An Insider’s Guide to Denim Fabric Defects: A Procurement Playbook

As a fabric industry professional with 20 years of experience, I also started out in fanric sales. Back then, I not only had to sell products but also personally handle fabric procurement. Therefore, I fully understand the pressures faced by procurement teams.

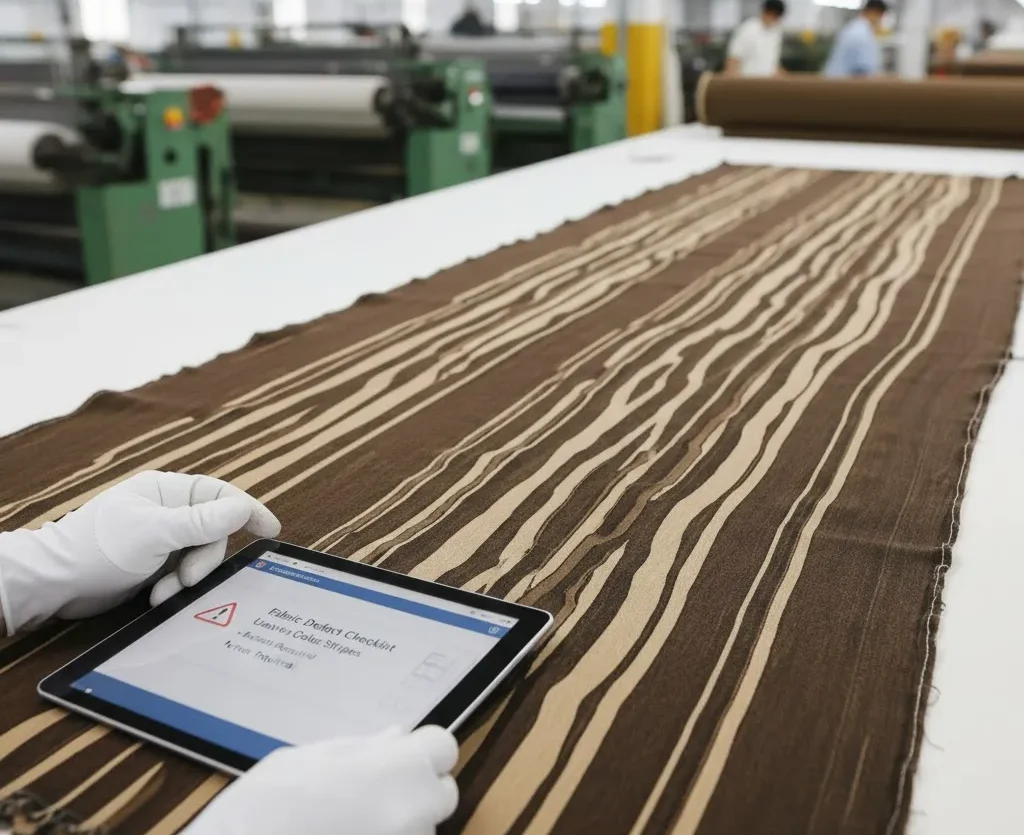

The procurement team’s job isn’t just to negotiate prices; it’s to ensure the safety of the entire production line. A seemingly minor flaw on a specification sheet or sample reel can lead to significant production delays, rejection of a fabric batch due to quality issues, and ultimately, significant financial losses.

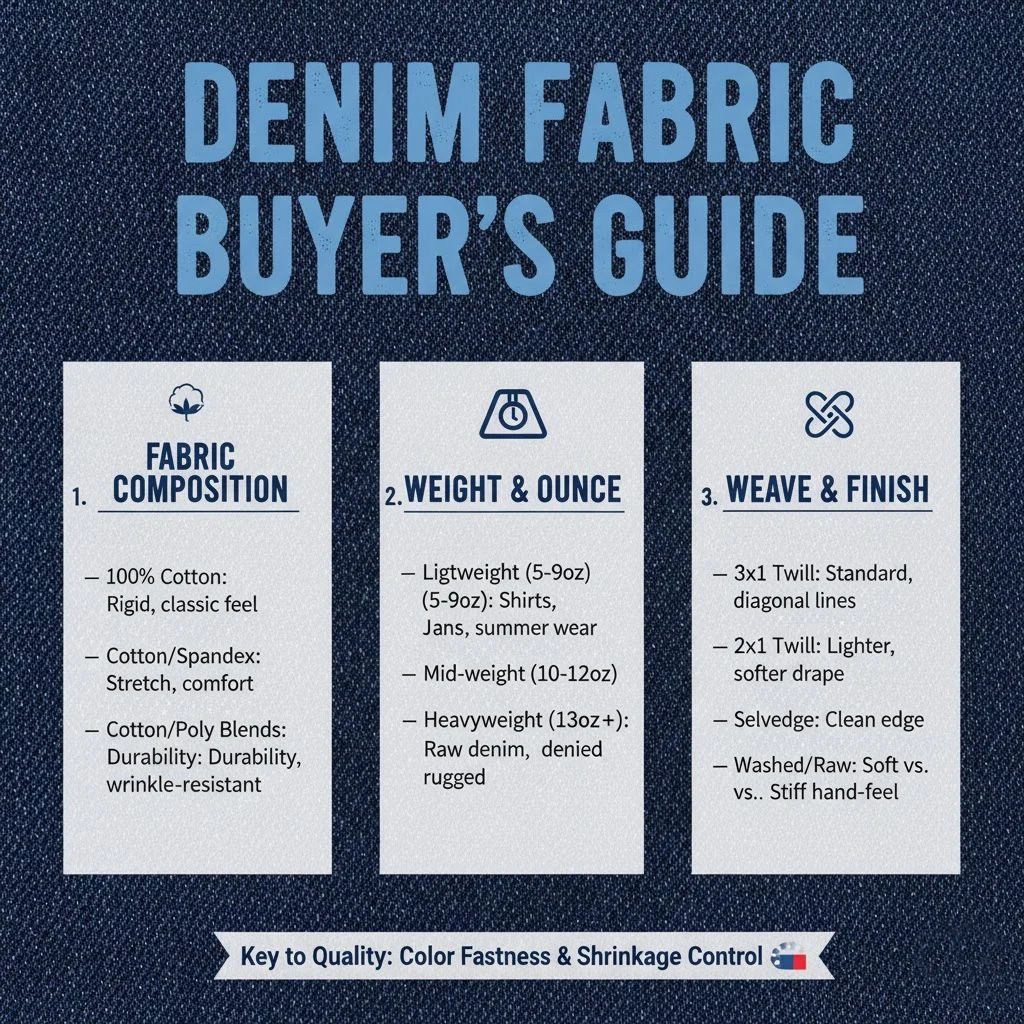

Therefore, identifying denim fabric defects is also a lesson that purchasers must take! Before you can spot flaws, however, you need a solid grasp of the material itself. Once you have that foundation, learning to identify potential issues becomes much easier.

This guide isn’t theoretical fluff pulled from textbooks. It’s built on the practical, day-to-day challenges and solutions we deal with right here on the factory floor.

I’m going to share the insider knowledge our own QC teams use, translating complex textile issues into actionable insights you can use immediately when evaluating samples or inspecting bulk goods.

My Goal is Simple:

To equip you, the procurement professional, with the expertise to assess denim quality confidently, communicate defect concerns precisely with mills (like ours!), and Ultimately, protect your production pipeline and your company’s bottom line. Let’s get started.

Setting the Standard: Understanding Defect Classification & Tolerance

First of all, as a fabric factory for more than 20 years, I need to state the fact that zero defects is an unattainable, cost-prohibitive goal in mass production. The real objective is to define, identify, and control defects within an acceptable tolerance level. This is where industry standards come into play.

Most factories and brands currently use a grading system similar to the four-point scale, or set acceptable quality limits (AQLs) based on standards such as ANSI/ASQ Z1.4. These systems classify defects based on their severity (minor, major, severe) and set a threshold for the number of defects allowed in a specific batch or lot.

Note: Understanding these denim quality standards is fundamental.

It’s less about finding if there are defects, and more about knowing which defects matter and how many are acceptable for your specific product’s quality tier and price point.

Common Weaving Defects: Flaws Born on the Loom

These defects originate during the fabric weaving process itself. They are often the most fundamental and can impact both the look and structural integrity of the final garment. Here’s how to check denim quality right from the raw fabric stage:

Neps & Slubs (Small Knots & Thicker Yarn Sections)

What they are: Neps are small, tangled knots of fibers, appearing like tiny white specks on the fabric surface. Slubs are thicker, elongated sections within the yarn itself.

How to Spot: Easily visible upon close inspection, especially on darker indigo fabrics where the white neps stand out. Slubs create noticeable thick lines in the weave.

Potential Impact: While sometimes intentionally created for a textured look (“slub denim”), unintentional neps and large slubs are generally considered aesthetic defects. Severe neps can sometimes create weak points in the yarn.

Factory Insight:

In our mill, excessive neps often point to issues in the early stages of yarn spinning, maybe related to the raw cotton quality or carding process. Slubs, if not intentional, usually indicate an irregularity during spinning. We monitor yarn quality rigorously to minimize these.

Barre Marks (Horizontal Streaks/Bands)

What they are: Noticeable horizontal bands or streaks running across the fabric width where the color or texture differs slightly.

Common Causes: Often caused by inconsistencies in yarn tension, yarn thickness variations between cones used on the loom, or slight differences in dye uptake if dyed yarns are mixed.

How to Spot: Lay the fabric flat under good, even lighting. Look across the width for repeating band patterns. They can be subtle.

Impact: Considered a major aesthetic defect, especially noticeable on large pattern pieces like jacket backs or full trouser legs. This is one of the key denim weaving defects we train inspectors to catch early.

Skewing / Bowing (Fabric Distortion)

What they are: Skewing is when the weft (horizontal) yarns are no longer perpendicular to the warp (vertical) yarns, causing the fabric’s grainline to slant diagonally. Bowing is when the weft yarns dip or curve in the center of the fabric width.

How to Spot: Lay the fabric flat. Place a T-square or right-angled ruler along the selvedge (edge). The weft threads should run perfectly parallel to the ruler’s horizontal edge. Any deviation indicates skew or bow.

Impact: A critical defect. If fabric is skewed or bowed, garment panels cut from it will twist or hang incorrectly after washing, leading to poor fit and high return rates.

Broken Picks / Ends (Missing or Broken Threads)

What they are: A broken pick is a missing or broken weft yarn; a broken end is a missing or broken warp yarn.

How to Spot: Appears as a thin line or gap running horizontally (broken pick) or vertically (broken end) in the fabric weave.

Impact: Weakens the fabric structure at that point and is a clear visual defect. Depending on size and location, it may necessitate cutting around the flaw, reducing fabric yield.

Dyeing & Finishing Defects: Imperfections in Color and Wash

These flaws arise during the dyeing of the yarn or fabric, or during the later garment washing and finishing stages. What causes streaks in denim dye? Often, it’s inconsistencies in the process.

Color Streaks / Shading (Uneven Dye Application)

What they are: Noticeable variations in color depth or hue, appearing as streaks, patches, or bands across the fabric or garment.

Causes: Can result from improper dye mixing, uneven tension during dyeing, temperature fluctuations, or issues with chemical application.

How to Spot: Inspect under standardized lighting (like a D65 lightbox). Compare different areas of the same roll or different garments from the same batch.

Impact: A major aesthetic flaw, leading to inconsistent product appearance.

Color Bleeding / Crocking (Poor Color Fastness)

What they are: Crocking is the transfer of color from the denim onto another surface (like skin, upholstery, or other clothes) through rubbing. Bleeding is the loss of color when the fabric gets wet.

How to Spot: Perform a simple rub test using a clean white cloth (both dry and slightly damp). Check the care label or supplier test report for fabric color fastness test grades (referencing standards like ISO 105-X12 for Crocking).

Impact: A major quality issue that leads to customer complaints and potential damage to other items. While some indigo crocking is expected initially, excessive bleeding or low grades are unacceptable.

In-House Test Data: Verifying Performance

Quality isn’t just about looks; it’s about measurable performance. Here are typical results from our in-house lab for our standard 12 oz indigo denim, ensuring it meets key denim quality standards:

| Parameter | Average Reading | Observation |

|---|---|---|

| Fabric Weight (GSM) | 340 – 450 g/m² | Heavier denim shows higher durability and body |

| Tensile Strength (Warp) | > 420 N | Measured on internal tensile tester |

| Colorfastness to Wash | Grade 4-5 | Excellent indigo retention after 5 cycles |

All data were generated using calibrated GSM cutters, dynamometers, and colorfastness testers. We maintain strict record sheets for every batch.

Uneven Washing / Abrasion Marks

Image of uneven wash-wear marks on denim.

What they are: Inconsistent or patchy results from stone washing, enzyme washing, or hand-sanding processes. This answers what does uneven wash mean?

How to Spot: Compare different garments from the same wash batch, or different areas of the same garment (e.g., left leg vs. right leg). Look for obvious differences in the level of abrasion, color lightness, or pattern application.

Impact: Results in inconsistent product appearance within a batch, a sign of poor process control in the laundry.

Finishing Residues (Chemical Stains or Odors)

What they are: Lingering chemical smells or visible stains (often yellowish or brownish) resulting from incomplete rinsing or neutralization after chemical treatments (like bleaching or resin application).

How to Spot: Smell the fabric. Inspect closely for discolored patches, particularly around seams or thick areas where chemicals might pool.

Impact: Can cause skin irritation for the end consumer and indicates poor finishing practices. High-quality production includes thorough rinsing and adherence to standards like OEKO-TEX® STANDARD 100 for chemical safety.

Sewing & Construction Defects: Issues Arising During Garment Assembly

Even perfect fabric can be ruined by poor sewing. While technically garment defects, buyers inspecting finished goods must also check these common sewing problems in jeans:

Skipped Stitches / Broken Stitches

What they are: Gaps in the sewing line where the needle failed to form a stitch, or where the thread has broken.

How to Spot: Visually inspect all seams, especially high-stress areas like the crotch, waistband, and pocket attachments. Gently pull on seams to check integrity.

Impact: Severely weakens the seam, leading to premature unraveling and garment failure. A critical defect.

Seam Puckering (Gathered or Wavy Seams)

What they are: Rippling or waviness along a seam line, caused by uneven fabric feeding or incorrect sewing tension.

How to Spot: Lay the garment flat. Seams should lie flat and smooth. Puckering is visually obvious.

Impact: Primarily an aesthetic defect, giving the garment a low-quality appearance. Can sometimes affect fit if severe.

Misaligned Pockets / Components

What they are: Pockets, belt loops, labels, or other components that are sewn on crooked, unevenly spaced, or not symmetrical.

How to Spot: Visually check the placement and alignment of all sewn-on parts relative to seams and garment edges.

Impact: Major aesthetic flaw, indicating careless construction.

Incorrect Stitch Count (SPI – Stitches Per Inch)

What they are: The number of stitches per inch of seam is too low or inconsistent.

How to Check: Use a small ruler to count the stitches within one inch along a major seam (like the inseam or outseam). Consistent SPI is crucial.

Impact: Low SPI results in weaker seams. Inconsistent SPI looks unprofessional.

A Practical Inspection Checklist: Your Quick Reference

Here is a simplified denim inspection checklist summarizing the key points:

Weaving Defects:

- [ ] Check for excessive Neps/Slubs.

- [ ] Scan for Barre Marks across the width.

- [ ] Verify Grainline (check for Skew/Bow).

- [ ] Look for Broken Picks/Ends.

Dyeing/Wash Defects:

- [ ] Check for Color Streaks/Shading variations.

- [ ] Perform Dry & Wet Crocking test.

- [ ] Compare garments for Wash Consistency.

- [ ] Smell for Chemical Odors, look for residues.

Sewing Defects:

- [ ] Inspect Seams for Skipped/Broken Stitches.

- [ ] Look for Seam Puckering.

- [ ] Check Alignment of pockets, loops, etc.

- [ ] Verify Stitch Count (SPI) consistency.

Beyond Identification: Communicating & Preventing Defects

Identifying defects is reactive; preventing them is proactive. How to prevent defects in denim production? It starts with clear communication and robust processes.

The Power of a Detailed Tech Pack & Approved Samples

Your tech pack is the blueprint. It must clearly define not just the design, but also the acceptable quality standards. An approved pre-production sample serves as the “golden standard” that bulk production must match. Ambiguity in specs is an invitation for defects.

Establishing Clear Quality Standards in Your Contracts

Your contract with the supplier should explicitly state the AQL levels, the inspection method (e.g., 4-Point System), and the consequences for failing an inspection (e.g., rework, discount, rejection). This sets clear expectations from the outset.

(For a comprehensive look at managing the supplier relationship and the entire sourcing workflow, please refer to our Denim Fabric Sourcing Guide).

Conclusion: Quality is Not an Accident

Identifying denim fabric defects is a critical skill for anyone involved in bringing denim products to market. It requires a keen eye, a systematic approach, and a solid understanding of how the fabric is made.

Rigorous inspection, clear communication, and partnering with quality-conscious manufacturers like ourselves are essential for building a brand known for its consistency and value. We believe in transparency and stand behind our quality control processes.

(We maintain rigorous Quality Control Standards throughout our production line. If you have specific quality requirements or need assistance developing your inspection protocols, please speak with our technical team.)

FAQ – Frequently Asked Questions for Buyers

What are common flaws/defects in jeans/denim?

Common denim defects fall into three main categories: Weaving Defects (like neps, slubs, barre marks, skewing), Dyeing & Finishing Defects (color streaks, poor color fastness, uneven washing, chemical residues), and Sewing Defects (skipped stitches, seam puckering, misaligned components).

How do you check denim quality before buying fabric?

Check key properties like ounce weight (for substance), fiber content (100% cotton vs. stretch), weave quality (look for uniformity, no excessive neps/slubs/barre), and color fastness (request lab reports for crocking, washing, and light fastness). Also analyze craftsmanship details like selvedge quality and dye depth.

What do common denim weaving defects (slubs, neps, barre) look like?

Neps are small, tangled fiber knots appearing as tiny white specks. Slubs are thicker, elongated sections in the yarn, creating visible thick lines. Barre marks are noticeable horizontal bands or streaks across the fabric width where color or texture differs slightly. (Ideally, the article would include images for visual reference).

What causes streaks in denim dye?

Color streaks or uneven shading in denim dye are typically caused by inconsistencies during the dyeing process. This can include improper dye mixing, uneven tension on the fabric as it passes through the dye bath, temperature fluctuations, or problems with chemical application.

What are common sewing problems in jeans?

Common sewing problems include skipped or broken stitches (weakening seams), seam puckering (wavy seams due to tension issues), misaligned components (like pockets or belt loops sewn crookedly), and an incorrect or inconsistent stitch count (SPI), which affects seam strength and appearance.

What does uneven wash mean in denim finishing?

Uneven wash refers to inconsistencies in the color fading or abrasion effects applied during the wet process (like stone washing or enzyme washing). It means some areas of the garment, or different garments within the same batch, show noticeably different levels of lightness, abrasion patterns, or overall color tone.

What is an acceptable defect level for denim (AQL / 4-Point System)?

There’s no single universal level; it depends on the brand’s quality standards and price point. However, the industry commonly uses the 4-Point System for fabric inspection and AQL (Acceptable Quality Limit) standards (like AQL 2.5 or 4.0 for major/minor defects) for garment inspection to define the maximum number of permissible defects per batch.

Is there a standard denim inspection checklist?

While many factories and brands develop their own detailed checklists, a standard inspection covers key points in Weaving (neps, slubs, barre, skew), Dyeing/Wash (color consistency, streaks, fastness), and Sewing (stitch integrity, alignment, puckering, SPI). Our article provides a practical checklist summarizing these points.

How can defects be prevented in denim production?

Defect prevention relies on clear communication and robust processes. Key steps include: providing detailed tech packs with precise specifications, approving physical reference samples and pre-production samples rigorously, establishing clear quality standards in contracts, sourcing from reliable suppliers with good quality control systems, and conducting thorough in-line and final inspections.