Introduction: Making Strategic Sourcing Decisions

Successful denim fabric sourcing is more than finding a blue cotton fabric; it’s a strategic process that impacts your garment’s character, cost, and market position.

This is not a beginner’s introduction; this is a professional’s playbook. My goal is to equip you with the framework to navigate the sourcing process like a seasoned product manager, making decisions that are precise, profitable, and true to your brand’s vision.

We will deconstruct the critical stages, from quality assessment to post-purchase logistics, providing the expert insights needed to build a successful denim program.

Before You Source: Understanding the Fundamentals

A successful sourcing journey begins with a solid foundation of product knowledge. If you’re new to fabric sourcing, I strongly recommend first reading our article on what denim is to confirm your sourcing needs before understanding the specific sourcing process.

How to Choose High-Quality Denim: Professional Evaluation Criteria

The first step in any sourcing process is knowing what to look for. When a fabric sample lands on your desk, you need to be able to assess it with a critical, expert eye.

👷 Factory Experience: What We Inspect First

In our factory, we often start every denim evaluation with yarn count and weaving tension. We record GSM and thread density before dyeing to predict the final hand-feel and drape. When GSM drops below 11 oz, the denim tends to lose its backbone during washing, while heavier 14–16 oz qualities give that authentic, rugged texture buyers expect.

We also check the fiber composition closely. In our in-house blend tests, 98% cotton with 2% elastane shows the best balance between recovery and breathability for jeans production. 100% cotton styles, on the other hand, are preferred by heritage brands seeking the pure raw-denim fade.

Key Fabric Properties to Inspect

These are the objective, measurable qualities that define a denim’s performance.

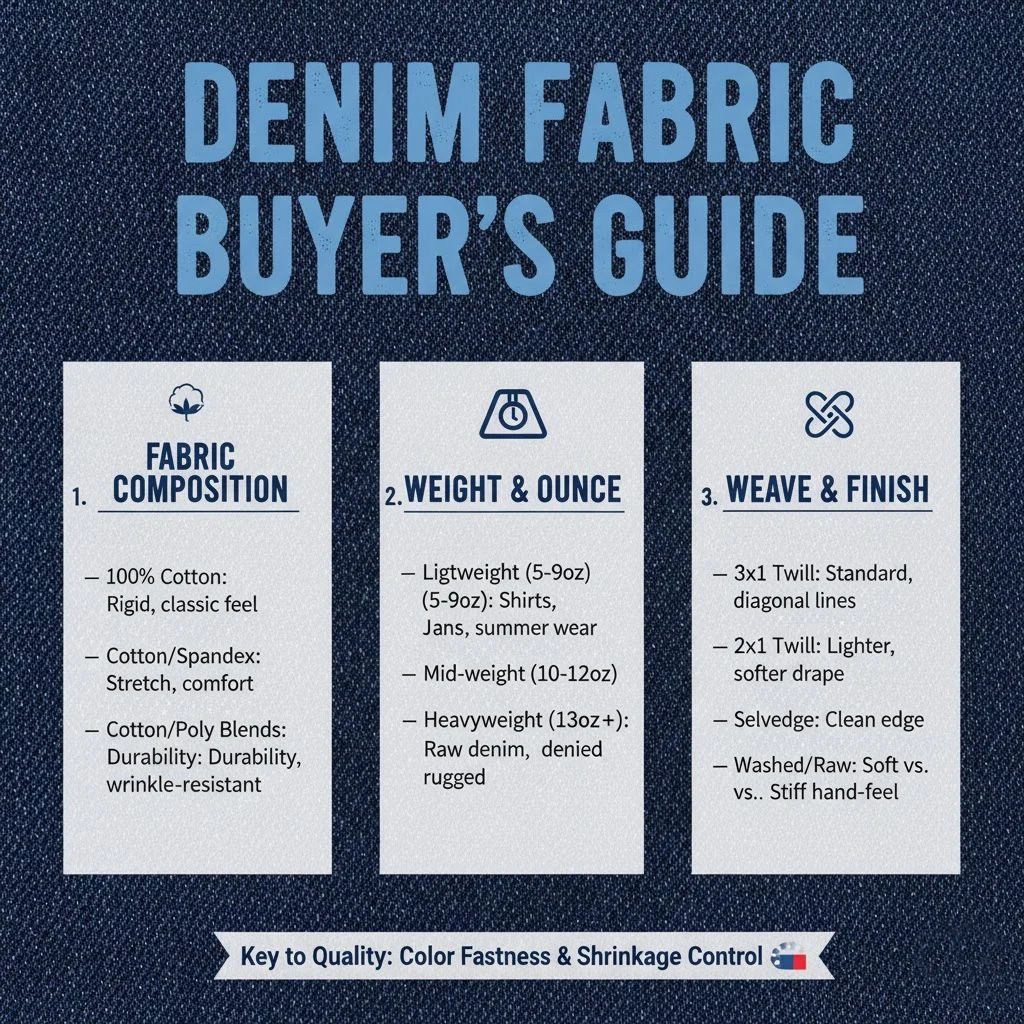

Ounce Weight (oz/yd²): The Fabric’s Skeleton and Feel

The most fundamental of denim fabric characteristics is its weight, measured in ounces per square yard. This metric, often governed by standards like ASTM D3776, dictates the fabric’s structure, drape, and seasonality. We categorize it into three main tiers:

- Lightweight (<12oz)

- Mid-weight (12-16oz)

- Heavyweight (>16oz)

Each serves a different strategic purpose. For an in-depth analysis of how weight interacts with yarn, see our Fabric Weight & Yarn Count Guide.

Fiber Content: 100% Cotton vs. Stretch Blends

The tag what fabric is denim made of almost always starts with cotton, but the modern answer is more nuanced.

- 100% Cotton: This is the heritage standard, offering maximum durability and the potential for authentic, high-contrast fading. It’s the only choice for vintage reproduction and “raw denim” purists. This is the classic denim fabric material.

- Stretch Denim Fabric: Typically a blend of 98-99% cotton and 1-2% elastane (Spandex/Lycra). This provides the comfort and close fit demanded by the mass market, particularly in skinny and slim-fit silhouettes. The key is to source stretch denim with good recovery to prevent bagging at the knees.

Weave Quality: Density, Defects, and Uniformity

Look closely at the fabric’s surface. A quality denim will have a tight, consistent twill weave with clearly defined diagonal lines. Hold the fabric up to the light; you should not see significant variations in thickness or slubs (thicker spots in the yarn), unless it’s an intentional “slub denim” design. Poor weave quality can lead to issues with durability and appearance after washing.

Color Fastness & Strength: A Critical Quality Indicator

Color fastness determines how well a fabric resists color loss, while tensile strength measures its durability. For denim, both are paramount. Our in-house lab uses calibrated GSM cutters, dynamometers, and colorfastness testers to generate data for every batch. We maintain strict record sheets and aim for these standards:

- Tensile Strength (Warp): We target a strength of > 420 N on our internal tensile testers, ensuring the fabric can withstand the rigors of production and daily wear.

- Colorfastness to Washing: Our standard is Grade 4-5, which indicates excellent indigo retention even after 5 wash cycles. This means the deep, rich color your customers fall in love with will last.

Core Craftsmanship Details to Analyze

Beyond the basic specs, these details signal a higher level of quality and craftsmanship. This is how to check denim quality like an expert.

1,Selvedge: The Mark of Heritage Craftsmanship

Selvedge denim fabric is woven on vintage shuttle looms, creating a clean, tightly woven edge that won’t unravel.

What to Look For in Quality Selvedge: Don’t just look for the edge itself. A high-quality selvedge fabric will feel noticeably denser and more substantial than wide-loom denim of the same weight. The weave should be tight and uniform right up to the clean edge.

2,Dyeing Process: The Depth and Character of the Indigo

Look at the color. True indigo ring-dyeing is the foundation for beautiful, natural fading.

What to Look For in Quality Dyeing: A high-quality indigo dye job is not a flat, uniform blue. Look closely at the yarns. You should be able to see a grinning effect, where the white core of the yarn is subtly visible through the deep blue surface.

3,Finishing Process: The Importance of Sanforization

Has the fabric been sanforized? This is a mechanical pre-shrinking process that provides dimensional stability.

What to Look For in Quality Finishing: A professional supplier will provide a specific, tested residual shrinkage percentage (e.g., shrinkage: <3% in warp and weft). This data-backed claim is a key indicator of a reliable manufacturer.

Note:But quality goes deeper than just the finished fabric. At a professional mill, it starts with the raw materials.

🧵 Material Selection Insights

When sourcing yarns, our team inspects ring-spun cotton slivers under magnification to ensure fiber uniformity. For elasticity, we specify low-shrink spandex from top-tier suppliers, guaranteeing recovery of over 95% after stretching. Before bulk production, we always weave a 10-meter pilot sample on our R&D loom to evaluate surface neps and selvedge alignment. This step helps our buyers avoid costly defects in full production runs.

Selecting Denim for Different Applications

The specifications you choose must align with your final product.

Apparel Applications

Denim Fabric for Jeans & Trousers

For a classic, all-season jean, a 12 oz denim fabric to 14 oz denim fabric is the industry sweet spot.

Jackets & Outerwear

Heavyweight denim for jackets is essential. Look for 13oz and up.

Shirts & Dresses

Here, you need lightweight denim, typically under 10oz.

Industrial & Home Applications

Upholstery

Requires extremely high durability and color fastness to light.

Workwear

The primary focus is on abrasion resistance and tear strength.

Sourcing Negotiations and Contract Essentials

Once you’ve identified the right fabric, the commercial process begins.

Key Negotiation Tactics

- Negotiate Beyond Price: Discuss payment terms, bulk discounts, and Incoterms (FOB vs. EXW).

- Leverage Your Volume: Share your projected annual volume with potential denim fabric suppliers.

- Discuss Quality Standards Upfront: Agree on the acceptable defect rate before signing the contract.

Essential Contract Points

Your purchase order must be precise. It should include detailed fabric specs, quality control standards (e.g., AQL 2.5), a firm delivery schedule, and testing requirements.

Verify Certifications and Traceability

A reputable supplier should be able to provide proof of their quality and ethical standards. This is a non-negotiable part of our process.

📜 Our Standards & Traceability:

Our denim production line is OEKO-TEX® Standard 100 Certified, ensuring it’s free from harmful substances. Our quality management for finishing and inspection is ISO 9001:2015 Certified. We operate an in-house traceability system from the yarn lot to the final roll barcode, and every roll that leaves our mill carries a printed QC label with inspector ID, batch number, and GSM reading for full transparency.

The Denim Sourcing Inspection Checklist

| Phase | Action Item | Key Deliverable / What to Check |

|---|---|---|

| 1. Development | Finalize design, target cost, and specs. | A detailed Tech Pack with all fabric info. |

| 2. Supplier Search | Research and vet potential mills. | Shortlist of 3 qualified denim fabric manufacturers. |

| 3. Sampling | Request and review fabric swatches. | Approved denim fabric swatch that meets targets. |

| 4. Lab Dips | Approve color standards under different lights. | Approved color sample (Lab Dip). |

| 5. Bulk Order | Issue a detailed Purchase Order (PO). | Signed PO with all terms and conditions. |

| 6. QC | Arrange for in-line and final inspections. | A passing QC Report based on agreed AQL. |

| 7. Shipping | Approve shipment and receive documents. | Bill of Lading, Commercial Invoice, Packing List. |

Common Denim Sourcing Mistakes to Avoid

Here are the top three costly errors to avoid:

Ignoring Total Cost of Ownership

A cheaper per-yard price is meaningless if the fabric has a lower yield, higher shrinkage, or fails QC.

Skipping a Rigorous Sample Approval Process

You must approve a bulk fabric swatch before they start cutting.

Vague Communication on Washes

“I want a light blue wash” is not a professional instruction. You must provide a physical reference garment.

What to Do After the Purchase Order?

Placing the order is just the beginning.

Quality Control (QC)

A professional fabric quality control process is non-negotiable. Hire a third-party inspection team.

Logistics and Customs

Coordinate with your freight forwarder well in advance. [Learn more about export clearance]

Denim Care and Storage in a Warehouse

Your investment must be protected.

Care Tips

Always recommend washing denim inside-out, in cold water, with like colors. Always hang to dry. For comprehensive instructions, our detailed guide is the perfect resource.

For detailed customer-facing tips, you can refer them to our comprehensive guide →

Storage Considerations

How to store fabric rolls is a critical aspect of inventory management. Store them horizontally in a clean, dry, and dark environment.

Conclusion: From Buyer to Strategic Partner

Mastering denim fabric sourcing is about evolving from a simple buyer into a strategic product developer.

We don’t just supply fabric; we partner with brands to build successful denim programs. You can learn more about our values on our About Us page.

FAQ – Frequently Asked Questions for Buyers

What is the most important metric when choosing denim?

While ounce weight is a fundamental starting point, there’s no single most important metric. A strategic buyer evaluates all denim fabric characteristics—weight, fiber, and weave quality—in relation to the final product’s goal.

How can I differentiate denim for different uses?

The primary differentiators are weight and fiber content. For performance, look for stretch denim fabric. For heritage jeans, prioritize 100% cotton and consider selvedge denim fabric. For shirts, look for lightweight denim under 10oz.

What are some practical negotiation tips?

Beyond price, negotiate on terms. Ask for a small discount for a larger upfront deposit, or better payment terms (e.g., Net 60) if you are a returning customer.

What are the most critical clauses in a sourcing contract?

The three most critical clauses are:

1-,Detailed product specifications with agreed tolerances.

2,The agreed-upon Quality Control standard (AQL) and consequences of failing an inspection.

3),A firm shipping date with defined penalties for delays.

What is the best way to store bulk denim fabric?

The best practice for denim fabric warehouse storage is to keep rolls horizontal on sturdy racking systems in a climate-controlled warehouse. For deeper insights on textile science, you can explore resources like the The Textile Institute.