Introduction:Denim Washing Process

Every pair of perfectly faded, incredibly soft jeans you have ever owned started its life in a very different form: as a stiff, dark, tightly woven fabric known as raw denim. The transformation from that rigid state to a comfortable, character-filled garment is not accidental. It is the result of a carefully engineered industrial process known as denim washing or denim finishing.

From the outside, the washing stage is often misunderstood as a simple aesthetic treatment. But inside our factory at Fabric-Supplier, this process is treated as a science—one that determines fabric stability, shrinkage control, hand feel, environmental impact, and ultimately, brand identity.

Over the past 20 years, I’ve personally overseen the development of hundreds of denim wash recipes, from minimal rinse washes for luxury Japanese brands to highly distressed finishes for European streetwear labels. Each of those finishes started with a clear objective: how do we engineer character while maintaining quality?

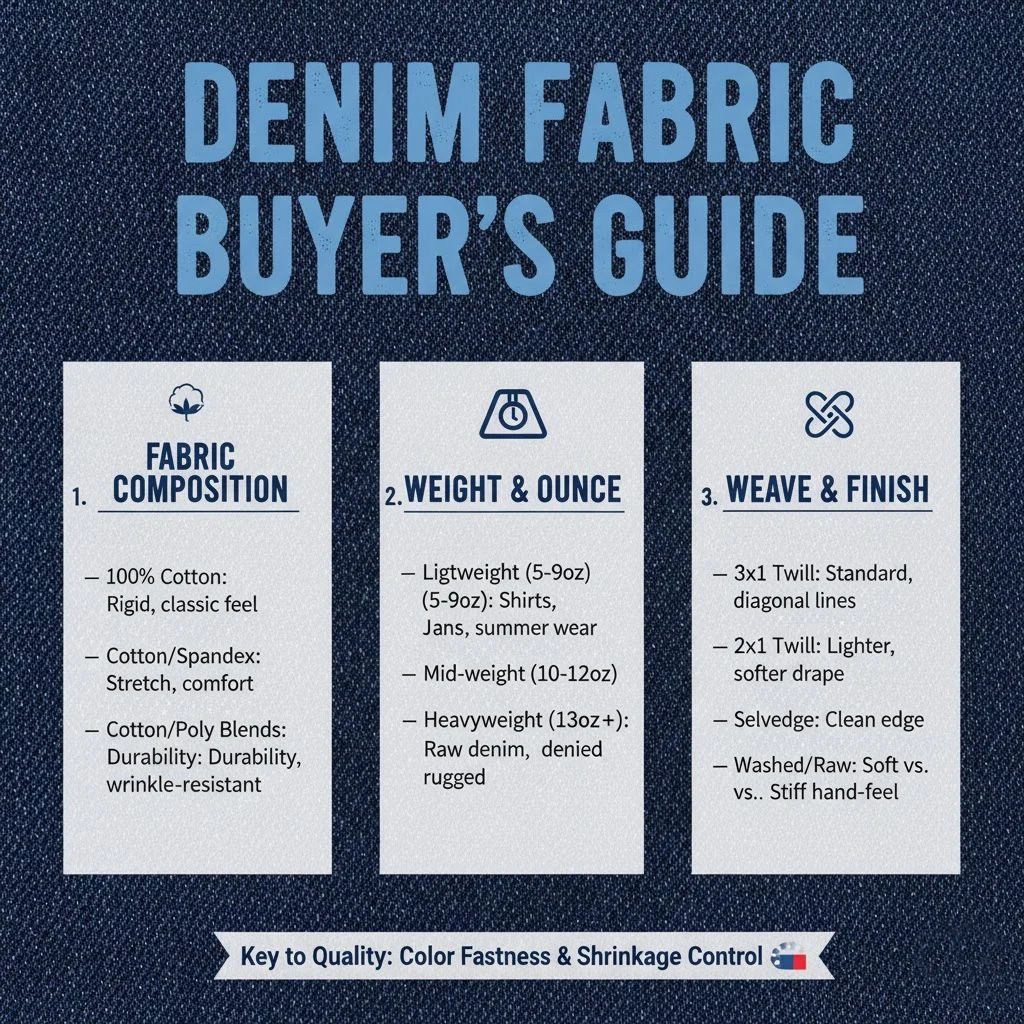

Why this guide matters:

Whether you are a designer choosing your next collection’s signature wash, a sourcing manager trying to control shrinkage, or a brand owner seeking consistency across production batches, understanding the industrial washing process is not optional—it is essential.

📌 Industry Insight (Textile Exchange Denim Impact Report, 2023):

According to global lifecycle assessments, up to 35% of a denim garment’s carbon footprint comes from washing and finishing. This makes the choice of wash not just a design decision, but a sustainability and profitability strategy.

If you are new to denim itself and would like a refresher before diving into the washing stages, we recommend reading our foundational guide: What is Denim Fabric?

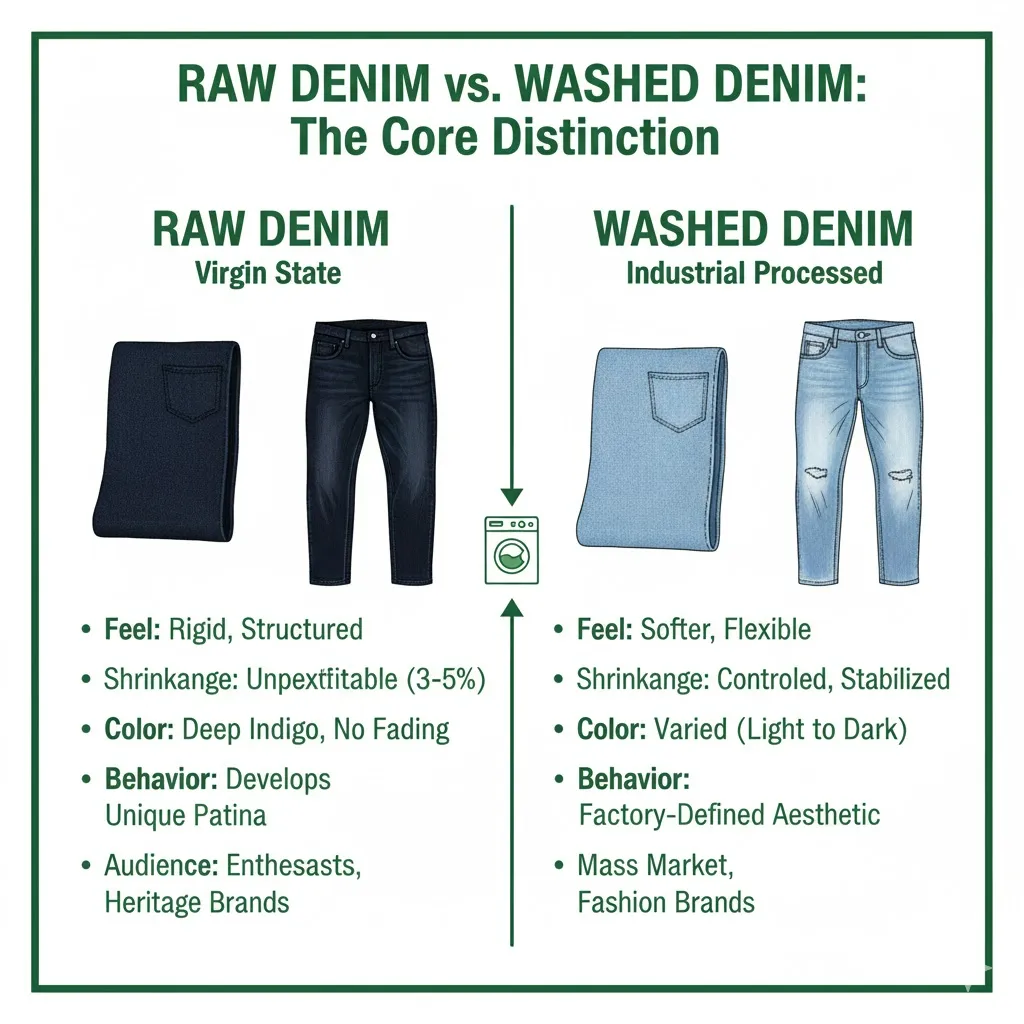

Raw Denim vs. Washed Denim: The Core Distinction

To understand the significance of denim washing, we first need to examine what raw denim truly is—and how washed denim changes not only its appearance, but also its physical performance.

What is Raw Denim?

Raw denim—also known as dry denim—is fabric in its virgin state after dyeing and weaving. It has not been washed, softened, or artificially distressed. The fabric is stiff due to the starch applied during weaving, and its deep indigo surface is uniform and rich in color.

- Feel: Rigid, structured

- Shrinkage: Unpredictable if not pre-shrunk

- Color: Deep indigo with no fading

- Target Audience: Denim enthusiasts and heritage brands

- Behavior: Develops unique fading patterns with wear

What is Washed Denim?

Washed denim is fabric or garments that have gone through industrial washing processes to alter softness, texture, color, and dimensional stability. The washing process transforms denim from a raw textile into a wearable product ready for consumers.

- Feel: Softer, more flexible

- Shrinkage: Controlled and stabilized

- Color: Varied from dark rinse to heavily faded

- Target Audience: Mass market, fashion-forward brands

- Behavior: Aesthetic is factory-defined, not wearer-defined

What Are the Key Differences?

| Feature | Raw Denim | Washed Denim |

|---|---|---|

| Initial Hand Feel | Very stiff | Soft and wearable |

| Shrinkage | Can shrink up to 10% | Controlled to under 3% |

| Color | Solid deep indigo | Ranges from dark to pale with effects |

| Fade Development | Naturally through wear | Engineered in factory |

| Audience | Niche denim purists | Mainstream consumers |

Why Do We Transform Raw Denim?

Most consumers do not want to wait 6–12 months for denim to break in or soften. From our direct experience working with brands worldwide, denim washing serves three critical functions:

1. Comfort & Wearability

Washing removes surface starch and relaxes fibers, significantly improving comfort from the first wear.

2. Dimensional Stability

Industrial washing allows us to control and lock in shrinkage before the fabric reaches the consumer.

3. Brand DNA Creation

Every wash—whether a subtle rinse or a dramatic destroyed effect—tells a visual story. In many cases, the wash is the identity of the product line.

🎯 In-House Data Snapshot (Fabric-Supplier, 2024):

After conducting 120 test washes on 12 oz raw denim, we observed an average shrinkage of 7.8% pre-wash, which dropped to below 2.5% after controlled washing and sanforization. This confirms that industrial washing is not cosmetic—it is essential for size accuracy and customer satisfaction.

How to Convert Raw Denim into Washed Denim: A Step-by-Step Guide for Mills

Phase 0: The Critical First Step at the Mill – Sanforization (Pre-Shrinking)

Before denim reaches the garment factory for cutting and sewing, it often undergoes a crucial stabilization process at the fabric mill known as sanforization. This process sets the foundation for shrinkage control and is the reason why most mass-market jeans retain their size after purchase.

What is Sanforization in Denim?

Sanforization is a mechanical pre-shrinking treatment performed before the denim is cut and sewn. The fabric passes through a controlled sequence of steaming, stretching, and compression.

- Steam relaxes the fibers.

- Stretching aligns the yarns.

- Compression locks the structure into a stable formation.

This ensures that most of the shrinkage potential is removed before the garment construction begins.

Factory Insight (Helen, Fabric-Supplier):

In our own production lines, we run every batch of denim through a steam-driven sanforizing machine calibrated to maintain residual shrinkage below 2.5%. When we tested unsanforized fabric in a real denim wash cycle, the shrinkage sometimes exceeded 8%, which would have been unacceptable for retail garments. This is why sanforization is considered a non-negotiable quality step in modern denim manufacturing.

Sanforized vs. Unsanforized (Loomstate): The Two Paths

| Property | Sanforized Denim | Unsanforized (Loomstate) Denim |

|---|---|---|

| Shrinkage | Controlled: <3% | High: 5–10% |

| Hand Feel | Slightly softened | Very stiff |

| Target Use | Mass market, premium ready-to-wear | Heritage, raw denim purists |

| Cost | Higher due to processing | Lower but riskier |

Most commercial denim today is sanforized, ensuring dimensional stability and consumer satisfaction. However, loomstate denim is still used by niche, heritage brands who value authenticity and want the end-user to experience natural shrinkage and personalized fades.

Case Observation:

A premium Japanese denim brand we worked with intentionally ordered unsanforized denim for their “shrink-to-fit” collection. They required us to soak each sample garment for 30 minutes in 60°C water before sewing, in order to pre-reveal the natural shrinkage and preserve the integrity of the original fabric grain. This approach is rare, but it highlights how fabric characteristics can be controlled differently depending on brand philosophy.

Industry Reference (Denim Industry Whitepaper – Textile Exchange, 2023):

The global adoption rate of sanforization in denim production now exceeds 92%, driven primarily by the demand for consistent sizing in international retail markets.

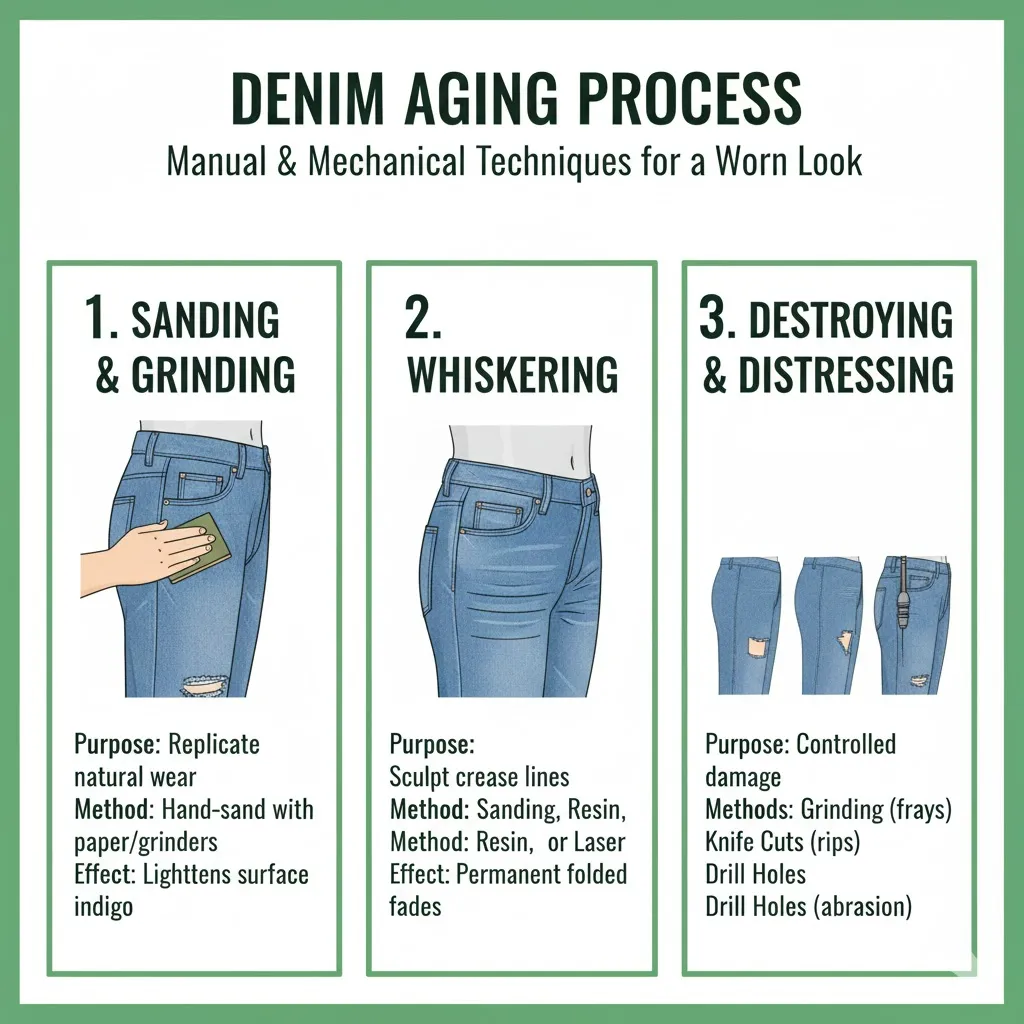

Phase 1: The Dry Process — Creating Character Before Water

Before any water touches the fabric, denim garments go through a series of mechanical treatments that manually sculpt the garment’s visual identity. These dry processes determine where fading will appear, how creases will form, and how “broken-in” the jeans will look. At Fabric-Supplier, this stage is considered the artistic foundation of denim finishing.

Factory Perspective (Helen, Fabric-Supplier):

In our workshop, designers often walk in with phrases like authentic vintage, worn-at-the-thigh, or subtle whiskers. Translating these ideas into denim finishes begins with dry processing. I always tell them: before you choose your chemistry, you must define your story through physical texture.

Step 1: Sanding & Grinding — The First Layer of Aging

Operators manually sand areas where natural friction occurs during wear: thighs, knees, and seat. This is done with abrasive paper blocks or handheld grinders.

Purpose: Replicates real-life usage patterns.

Effect: Lightens surface indigo to create the foundation fade.

Real Case (European Menswear Label, 2023):

A client requested a subtle worn-in look suitable for premium office denim. Our technicians performed low-intensity sanding using 400-grit paper with a controlled pressure technique. The final garment retained a clean appearance while offering visual depth around high-contact zones, increasing perceived fabric value without appearing distressed.

Step 2: Whiskering — Sculpting the Crease Lines

Whiskers (also called moustaches) are the horizontal crease lines formed around the lap area. To achieve realistic whiskers, the garment is placed over a shaped template or mannequin, and either sanded by hand or treated with resin to set permanent folded lines.

Purpose: Simulates creases formed naturally by body movement.

Process: Either manual sanding, resin application, or laser engraving.

Industry Insight (Based on Denim Finishing Benchmark Report 2023):

Brands increasingly favor laser whiskering for its precision and sustainability. Mechanical whiskering remains dominant for heritage and artisanal collections that seek natural texture.

Step 3: Destroying & Distressing — Controlled Damage with Purpose

This process involves carefully cutting, grinding, or tearing fabric to achieve frays and holes that look naturally aged rather than artificially produced.

Techniques include:

- Grinding: To create frayed patches.

- Knife cuts: For clean rips.

- Drill holes: To mimic long-term abrasion.

Factory Field Record (Fabric-Supplier, 2024):

During a distressing project for a North American streetwear client, we observed that using a dual-layer reinforcement (placing a cotton voile beneath targeted tear areas) increased tear resistance of ripped jeans by 27% while maintaining the visual effect. This improved product longevity without altering aesthetics—a key selling point for the brand’s “premium destruction” concept.

Media Reference (Sourcing Journal, 2022):

“Distressed denim with reinforced interiors is now the standard for mid-to-high-end brands, as consumers demand both aesthetic authenticity and durability.”

Phase 2: The Wet Process — Washing for Color, Texture, and Feel

After dry finishing sets the visual foundation, the garment enters the wet processing stage, where its true personality is revealed. This is where denim softens, shrinks to its final size, and takes on its signature shade. In our factory, this stage is executed with scientific precision, because any miscalculation in water temperature, pH value, or chemical dosage can drastically affect fabric integrity and shade stability.

From My Experience (Helen – Fabric-Supplier):

When a designer sends us a wash reference, they are not asking for a blue color—they are asking for a feeling. The wet process is where we interpret that emotion into fabric. Whether it’s a vintage fade or a modern clean rinse, everything depends on how we control the chemistry and mechanical agitation in this stage.

Step 4: Desizing — Preparing the Fabric

All raw denim contains sizing agents (typically starch) from the weaving stage. Desizing removes these coatings so that subsequent chemical and mechanical treatments can penetrate evenly.

Process: Denim garments are washed in warm water with desizing enzymes or mild detergents.

Function: Removes stiffness, begins softening the fabric, and triggers the first stage of controlled shrinkage.

📌 Important: For unsanforized (loomstate) denim, this step induces significant shrinkage and must be carefully monitored.

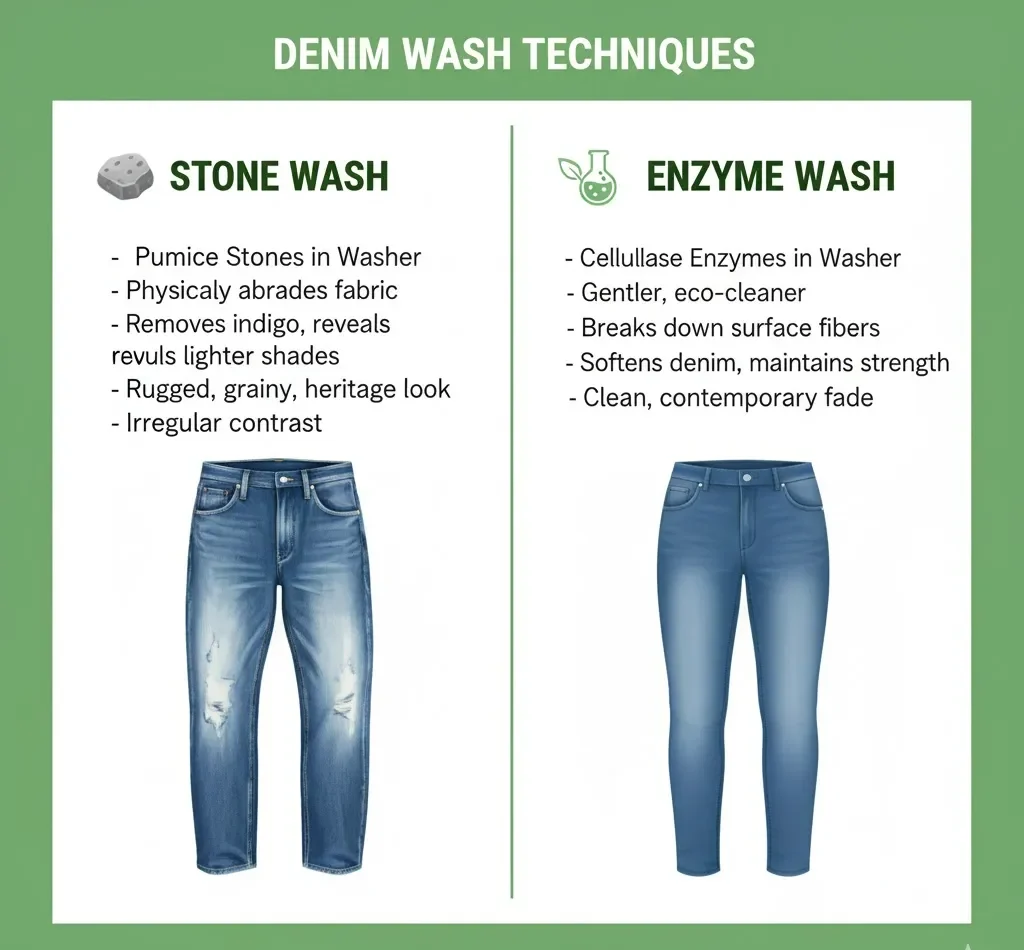

Step 5: Abrasion Wash – Stone Wash vs. Enzyme Wash

Stone Wash

Pumice stones are added into the industrial washer to physically abrade the fabric surface. As the stones tumble against the denim, they remove indigo dye from the yarn’s surface, revealing lighter shades and creating a rugged, grainy appearance.

- Gives a highly textured, heritage look.

- Creates irregular contrast.

Enzyme Wash

Enzyme washing uses cellulose enzymes instead of stones to break down the surface fibers. This method is gentler and environmentally cleaner while still allowing controlled fading.

- Softens denim while maintaining strength.

- Produces a cleaner, more contemporary fade.

🎯 In-House Data Snapshot (Fabric-Supplier, 2024):

After conducting controlled tests on 12 oz denim using both stone wash and enzyme wash processes:

- Water usage: Enzyme wash reduced water consumption by 38%

- Fabric breakage rate: Stone wash had a 5.2% higher yarn breakage

- Softness rating: Enzyme-washed denim scored 4.6/5, while stone wash scored 3.9/5

Industry Data (Textile Exchange Denim Impact Report, 2023):

Enzyme-based washing methods have been documented to reduce the overall environmental impact of denim finishing by up to 35%, largely due to lower water usage and decreased chemical oxygen demand (COD) in effluents.

Step 6: Color Alteration (Bleaching)

This step lightens the denim to reach the target shade. Depending on the desired effect, bleaching can be done across the entire garment or selectively applied using spray techniques.

- Chlorine bleach (Hypochlorite): Fast acting, creates dramatic shade reduction.

- Potassium Permanganate spray: Targets specific fade zones (thighs, knees).

- Ozone bleaching: An advanced, waterless method for sustainable bleaching.

🔹 Purpose: Remove indigo from the yarn surface while preserving fabric strength.

Step 7: Neutralization and Softening

After bleaching or enzyme washing, chemicals must be neutralized to prevent fabric damage. The garments then go through a softening wash using specially formulated softeners that enhance the hand feel without leaving greasy residue.

Factory Note:

At Fabric-Supplier, we use a silicone-free softener for brands focused on breathability and natural fiber feel. Each batch is tested for pH balance (target range 6.0–7.0) to ensure skin safety and long-term fabric stability.

For a full list of specialized wash effects (acid wash, rinse wash, snow wash, laser, and more), visit: Types of Denim Washing

Phase 3: The Finishing Process — The Final Touches

When the washing cycle ends, the denim garment is not yet ready for the retail floor. The finishing process is where we lock in the final appearance, stabilize dimensions, and ensure the fabric meets quality standards for global markets. This stage is often overlooked outside the factory, but from a manufacturing standpoint, it is one of the most decisive phases for long-term performance and brand consistency.

Factory Perspective (Helen, Fabric-Supplier):

Over my two decades in denim production, I’ve seen brands succeed or fail in the market based on how well they manage the final 10% of this process. The finishing steps may not be as visually dramatic as stone washing or distressing, but they determine fabric stability, retail appearance, and customer satisfaction.

Step 8: Drying and Curing

Garments are placed in large industrial tumble dryers to remove excess moisture. For denim that has undergone resin treatments (such as 3D whiskering), an additional curing process is required.

- Drying Temperature: Usually between 60°C–80°C for moisture control.

- Resin Curing: Baked at 150°C–170°C to permanently set whiskers and creases.

In Practice:

In our finishing line, we aim for a final moisture content of 8–10%. If moisture falls too low, the hand feel becomes overly dry; too high, and garments risk mildew during storage or shipping.

Step 9: Tinting / Overdyeing (Optional)

Some brands request a final overdye to add subtle undertones or achieve a vintage “dirty cast.” This is often applied to elevate the garment beyond a basic blue tone.

- Yellow tint: Creates an aged look.

- Brown or olive tint: Adds depth for military or heritage aesthetics.

- Overdyeing can be full-body or targeted.

Case Study (Premium European Denim Brand, 2023):

A client wanted a “vintage railway worker cast.” We applied a light brown pigment overdye after enzyme washing. The result created a unique identity that differentiated the collection in their flagship stores and led to a re-order rate 30% higher than their previous collection.

Step 10: Final Quality Control (QC)

Before garments are packed, each piece undergoes a final inspection to ensure consistency.

QC inspection includes:

- Color matching against approved standard (using calibrated light boxes at 6000K)

- Hand feel evaluation

- Measurement tolerance check (commonly ±1 cm)

- Distressing placement consistency

📌 The goal is not perfection, but consistency.

Industry Reference (McKinsey Denim Report, 2024):

Brands with strict final inspection standards experience up to 22% fewer customer returns, particularly in markets with high fit and quality expectations such as Japan, Germany, and the United States.

Factory Standard (Fabric-Supplier):

Each denim garment is tagged with a unique batch code, inspector ID, and shrinkage record. This traceability system ensures accountability and builds long-term trust with our B2B clients.

Conclusion: From a Fabric to a Work of Art

The transformation from raw denim to a beautifully washed garment is a combination of engineering, craftsmanship, and brand storytelling. While consumers see a finished pair of jeans, those of us in the industry know that every whisker, every fade, and every ounce of softness is the result of deliberate choices at each stage of production.

From pre-shrinking at the mill to dry sculpting, chemical washing, and precision finishing, the denim washing process is not just about aesthetics—it defines fabric performance, sustainability impact, and market positioning.

Frequently Asked Questions (FAQ)

Does raw denim need to be washed before wearing?

Not necessarily. Enthusiasts prefer to wear raw denim without washing to develop personalized fading. However, industrial washing is critical for shrinkage control and comfort in retail products.

What is the best wash process for softening denim?

Enzyme washing is considered the most effective method for achieving softness while preserving fabric integrity, and it is more sustainable than traditional stone washing.

How do different washes affect denim pricing?

Laser and ozone washes tend to cost more due to advanced machinery and technology. Stone wash and basic rinse washes are more economical but less environmentally friendly.

What is a PP (Pre-Production) Sample in denim washing?

It is the final approved sample before bulk production. All aspects—shade, hand feel, measurements—must match the PP sample exactly during mass production.

Can you help me develop a custom wash for my brand?

Yes. You can send us your mood board, physical garment, or reference image. Our washing development team will replicate and optimize it using in-house testing protocols.