The Fabric Weight Spec Sheet, Demystified: A Supplier’s 2025-2026 Guide

Hello, I’m a fabric supplier with over 20 years in this industry. I’ve seen countless promising brands make costly mistakes based on one simple thing: misunderstanding the numbers on a spec sheet.

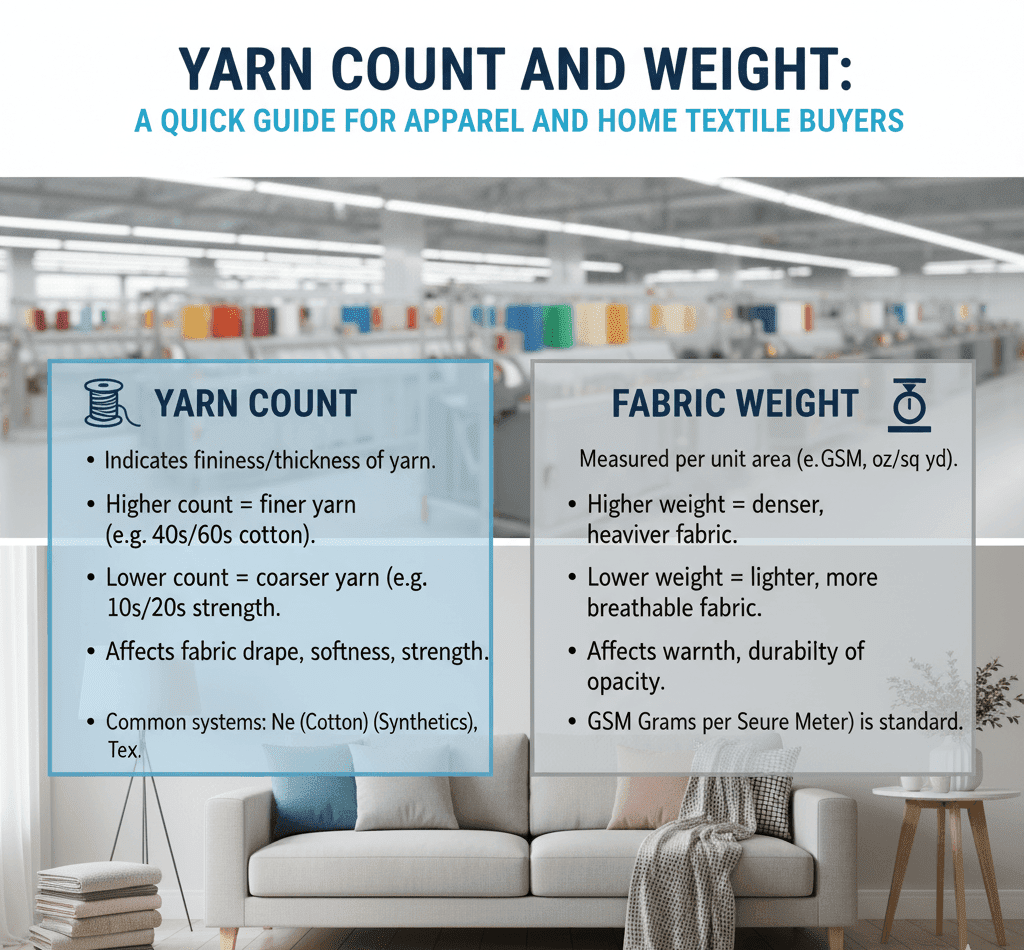

Two numbers, in particular, cause the most confusion: Yarn Count and GSM. This comprehensive fabric weight guide is the conversation I wish I could have with every new client. We’re going to move past dense definitions and give you the practical, real-world knowledge you need.

My goal is to make sure that after reading this, you can look at any fabric spec sheet and know exactly what it means for your product, your customer, and your bottom line.

What is GSM in Fabric? (The Measure of Substance)

GSM stands for Grams per Square Meter. It is a direct, objective measurement of a fabric’s density and weight. Simply put, it means “How much does this fabric weigh per square meter?”

Think of it like paper: a flimsy 80 GSM sheet is standard printer paper, while a 300 GSM sheet is a thick, substantial piece of cardstock. GSM clothing is a quick way to gauge a garment’s heft and quality feel.

Generally speaking:

120-160 GSM

This lightweight fabric is ideal for a summer T-shirt or shirt.

200-280 GSM

This medium-weight fabric is typically used for premium T-shirts and polo shirts.

300-400+ GSM

This heavier fabric is used for sweatshirts, hoodies, and jackets.

What is Yarn Count in Fabric? (The Foundation of Fineness)

Yarn count is a numerical value that indicates the fineness or thickness of a yarn. In simpler terms, it tells you how thin the thread is. For cotton and many other staple fibers, the most common system is the English Count (Ne), denoted by “S”.

Think of it like different types of pasta: a 10S yarn is like a thick spaghetti noodle, while an 80S yarn is like a delicate angel hair pasta strand.

Yarn count works on a proportional basis: the higher the number, the finer the yarn.

10S Yarn

Is thick and stiff, perfect for thick canvas or denim.

40S Yarn

Is finer and used for high-quality T-shirts.

80S or 120S Two-Ply Yarn

Is extremely fine and is designed for luxury dress shirts.

Understanding the different yarn count types and how to calculate yarn count based on weight and length is the mark of a true professional, but for buyers, simply knowing that “higher S = finer yarn” is the most important takeaway.

How Do Yarn Count and GSM Actually Work Together?

This is the most critical concept for any product developer. The yarn count and gsm relationship is not a simple one-to-one correlation. They are two independent but interacting variables you must balance.

It’s like baking a cake:

Yarn Count is your Ingredient Quality

(like using premium, finely milled flour vs. coarse, standard flour).

GSM is the Final Density of the Cake

(how much flour you pack into the pan). You can use the finest flour (high yarn count) to bake a very light, airy cake (low GSM) or a dense, heavy pound cake (high GSM).

The magic is in the combination.

The Biggest Misconception: Is Higher Always Better?

In my 20 years of experience, the most common and costly mistake I see is buyers chasing high numbers.

To this end, I’d like to point out that, whether it’s fabric weight or thread count, higher is definitely not better.

The best fabric isn’t the one with the highest numbers, but the one with the right numbers for the product’s intended use, target customer, and price point.

For example:

- ✗A 400 GSM t-shirt would be a failure—too thick, too hot, and too expensive.

- ✗A 120 GSM towel would be a disaster—thin, non-absorbent, and cheap-feeling.

The goal isn’t to maximize the specifications, but to optimize them.

How to Calculate or Measure Yarn Count and GSM

While your supplier will provide these specs, knowing how to verify them empowers you.

How to Measure GSM (A Practical Guide)

You can easily do this yourself to check a sample.

Tools You’ll Need:

- A digital gram scale (accurate to 0.01g)

- A circular fabric swatch cutter OR a ruler and sharp fabric scissors.

The Steps:

- Place your fabric on a flat surface. If using a cutter, press down firmly to cut a perfect circular sample.

- If using scissors, carefully measure and cut a 10cm x 10cm square. This is exactly 1/100th of a square meter.

- Place the cut sample on your digital scale and record the weight in grams.

- Take the weight and multiply it by 100. The result is the fabric’s GSM. For example, if your 10x10cm swatch weighs 2.2 grams, your fabric is 220 GSM.

How to Calculate Yarn Count

How to calculate yarn count is a more complex lab process, but understanding the logic is key. For the English Cotton Count (Ne) system:

The formula is based on a fixed weight (1 pound) and a fixed length unit (a “hank,” which is 840 yards). The yarn count is the number of 840-yard hanks that it takes to weigh exactly 1 pound.

Example:

If it takes 40 hanks (40 x 840 = 33,600 yards) of a yarn to weigh 1 pound, that yarn’s count is 40S.

This is why a higher number means a finer yarn—you need much more length of it to make up the same weight. You won’t perform this calculation, but now you understand the science behind the number. For more on textile testing standards, you can refer to organizations like ASTM International, which sets standards like ASTM D1059.

The Buyer’s “Cheat Sheet” for Common Fabrics

To make this practical, here is a quick-reference fabric weight chart I’ve developed.

| Product | Common Yarn Count (S) | Common GSM Range | My Experience-Based Advice |

|---|---|---|---|

| Basic T-Shirt | 26S – 32S | 160 – 180 | Good for promotional or mass-market tees. Focus on consistency. |

| Premium T-Shirt | 32S – 60S | 190 – 240 | This is the sweet spot for brands. A yarn count for t-shirts in the 40S range with 190 GSM feels soft and drapey; a 26S with 230 GSM feels structured and durable. |

| Hoodie/Sweatshirt | 21S – 32S | 300 – 500+ | GSM for hoodies is king. Below 320 is standard, 350+ feels premium, and 450+ is luxury heavyweight. |

| Luxury Bed Sheets | 60S – 120S | 120 – 160 | Don’t focus on GSM here; focus on high yarn count and thread count. The fabric should feel light and breathable, not heavy. This is where thread count vs yarn count becomes a critical topic. |

| Bath Towels | 16S – 21S (Two-Ply) | 500 – 800 | This is what is a good gsm for bath towels. 500 is good, 650+ is where true hotel-level luxury and absorbency begins. |

Simple Sourcing Tips & Mistakes to Avoid

Here is some simple advice to save you time and money.

Sourcing Tips

- Be Hyper-Specific: When you request a quote, provide your exact target specs. This shows you are a professional and leaves no room for error.

- Always Get a Sample: Never approve production based on a spec sheet alone. The “hand-feel” is a critical, unquantifiable metric that you must experience yourself.

- Request a Wash Test: Ask your supplier for wash test results for shrinkage and color fastness. Reputable suppliers will have this data. For more industry insights, check out publications like Sourcing Journal.

Mistakes to Avoid

- The “High Number” Trap: Don’t automatically assume a 60S shirt is better than a 40S shirt for your brand. The 60S shirt will be more expensive and might be too delicate for your target customer. Match the spec to the market.

- Forgetting Fiber Quality: The specs on this guide assume good quality cotton. A 200 GSM fabric made from premium Pima will be infinitely better than a 200 GSM fabric from low-grade cotton. Always specify the fiber type! This is a key lesson from our Pima vs. Egyptian Cotton Guide.

- Ignoring Finishing: A fabric can be “sanforized” (pre-shrunk) or have a softening finish applied. These processes can affect the final weight and feel, so always ask your supplier about the finishing.

Conclusion

Mastering fabric weight is about learning to speak the language of textiles. Yarn Count is the language of fineness; GSM is the language of substance. They are the two most powerful tools at your disposal for engineering a product that perfectly matches your vision and your customer’s expectations.

Use this guide as your foundation, always ask your supplier the right questions, and trust your hands. This guide is a cornerstone of our Textile Sourcing Hub; we’re here to help you succeed.

Ready to put this knowledge into practice? Contact our fabric experts today to discuss the perfect specs for your next collection.

Frequently Asked Questions (FAQ)

Q1: What is the difference between Yarn Count and Thread Count?

A: Yarn Count measures the fineness of a single yarn (the thread itself). Thread Count measures the density of a woven fabric by counting the number of threads in one square inch. A high yarn count (finer threads) is what makes a high, comfortable thread count possible.

Q2: Which GSM fabric is good for all-season use?

A: A mid-weight fabric in the 190-250 GSM range is incredibly versatile. It’s substantial enough for a high-quality t-shirt that’s not sheer, but not so heavy that it can’t be worn in moderate weather. This range offers a great balance of durability, comfort, and year-round appeal.

Q3: How much does GSM affect the price of a fabric?

A: GSM has a direct and significant impact on price. Since fabric is often purchased by weight (e.g., dollars per kilogram), a higher GSM fabric literally contains more raw material per square meter. Assuming all other factors are equal, a 250 GSM fabric will be more expensive than a 180 GSM fabric.