The Ultimate Pure Cotton Fabric Guide

The “100% Cotton” label is everywhere, from our most comfortable t-shirts to our softest bed linens, serving as a hallmark of natural comfort.

However, behind this simple label lies a complex and fascinating world stretching from the cotton field to the loom.

Your Expert Companion

This guide will serve as your expert companion, systematically demystifying everything about cotton fabric, transforming you from a casual consumer into a knowledgeable connoisseur.

So, what exactly is cotton?

Essentially, cotton fabric is a textile made from the seed fibers of the cotton plant, which undergo a series of processes including spinning and weaving. As a pure natural fiber, it possesses three innate and highly desirable qualities:

Excellent Breathability

allowing the skin to breathe freely

Superior Softness

hypoallergenic and gentle to the touch

Good Absorbency

helping to keep the body dry and comfortable

What determines the quality of pure cotton?

The single most critical factor that determines the quality of pure cotton is the physical length of its fibers.

Staple Length

Short Staple

↓ Higher Quality ↓

Long Staple

It’s a simple yet crucial metric: the longer the fiber, the stronger, smoother, and finer the yarn that can be spun from it. Consequently, fabrics made from long-staple cotton will far surpass those made from short-staple cotton in terms of softness, luster, and durability.

A Systematic Cotton Fabric Guide to Classification

The world of cotton fabric is rich and diverse. To understand it clearly, we can systematically classify it based on three core dimensions: the raw material’s origin, the textile processing techniques, and the final weave or knit structure.

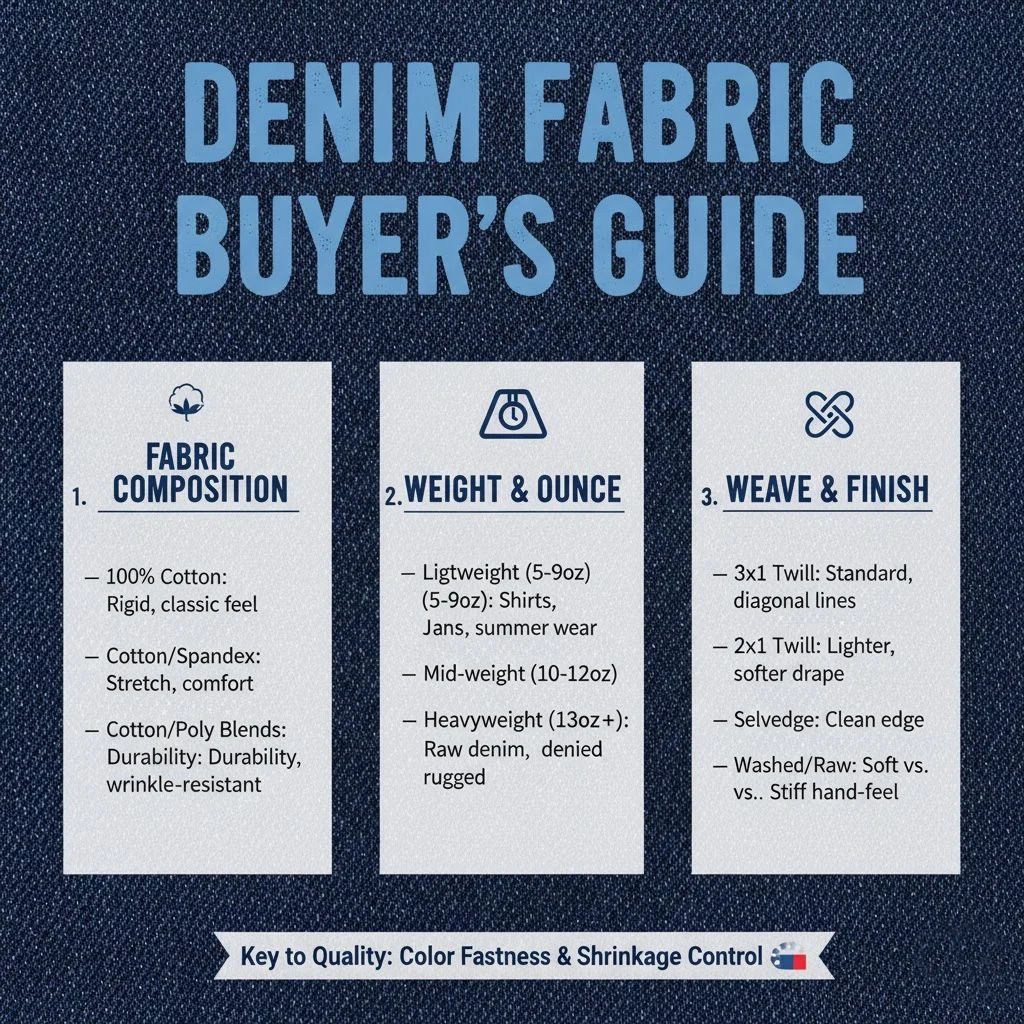

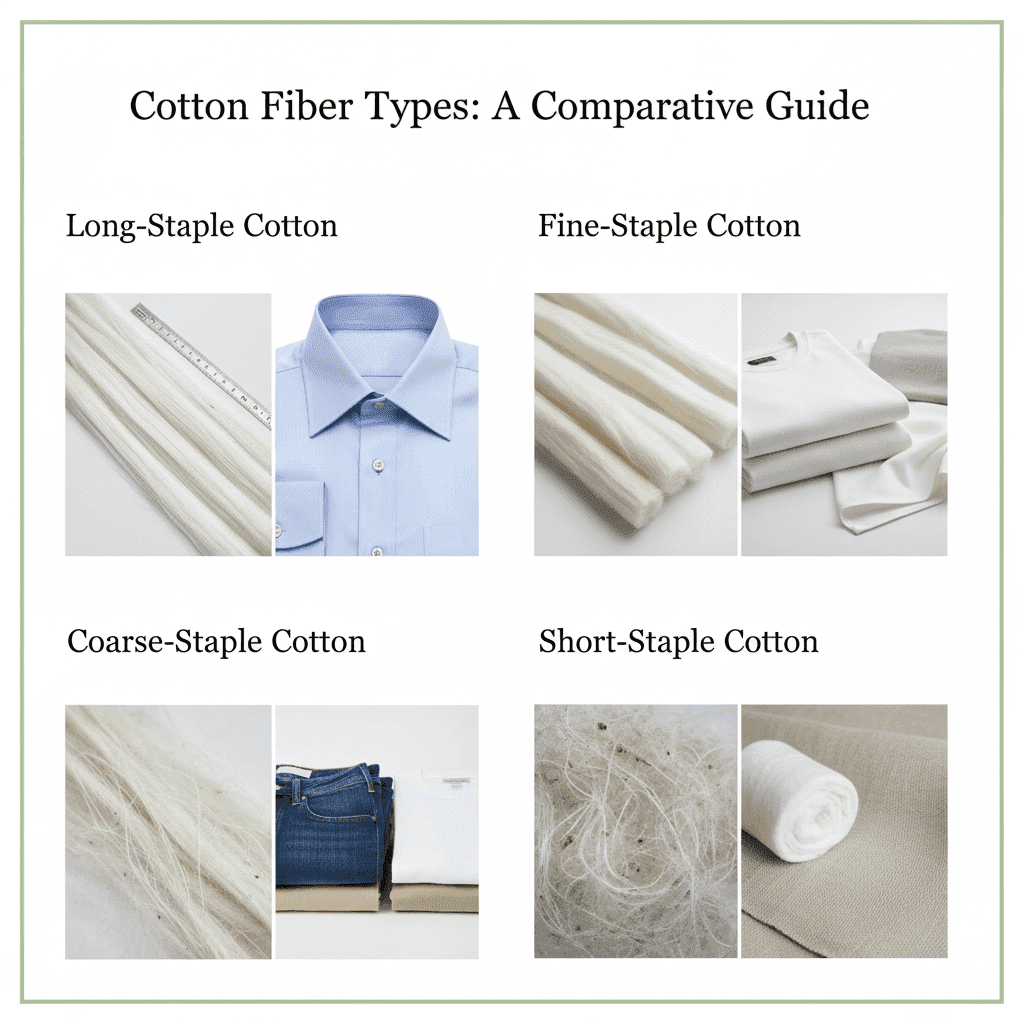

Classification by Raw Material: The Four Tiers of Staple Length

This is the most important and fundamental classification, directly determining the fabric’s “genetic” quality.

Long-Staple Cotton:

Fibers are 32mm and longer. This is the top tier of cotton, with rare and limited production. Due to the extremely long fibers, its yarn is strong, fine, and has a silk-like luster. It is primarily used for luxury goods like high-end bedding, premium dress shirts, and polo shirts. Famous examples include Egyptian and Pima cotton. (Read more: The Ultimate Showdown: Egyptian vs. Pima Cotton).

Fine-Staple Cotton:

Fibers range from 25–31mm. This is the backbone of mainstream high-quality cotton fabrics, also known as medium-long staple. Its overall performance is excellent, with superior softness, strength, and luster. It is the ideal choice for branded apparel, high-quality T-shirts, and premium home textiles, offering a great balance of quality and value.

Coarse-Staple Cotton:

Fibers range from 16–25mm. This is the most common and widely produced type of cotton, also known as Upland cotton. Its shorter fibers provide moderate performance and serve as the foundation for the vast majority of everyday cotton products, such as standard T-shirts, casual pants, and mass-market bedding.

Short-Staple Cotton:

Fibers are shorter than 16mm. Because the fibers are too short, the resulting yarn is weaker and has a rougher surface, making its applications very limited. It is generally not used for apparel and is primarily found in cotton batting, fillings, or low-cost industrial cloths.

Classification by Spinning Process

Different processing techniques can further unlock or enhance the potential of the raw cotton.

Carded Cotton:

This is the standard, fundamental spinning process. During carding, the cotton fibers are aligned and most impurities are removed. However, some shorter fibers remain, resulting in a fabric that can have a slightly rougher texture. It is the common choice for standard, everyday cotton goods.

Combed Cotton:

This is an additional, more refined step that occurs after carding. It uses fine-toothed combs to remove any remaining short fibers and impurities. As a result, combed cotton fabric has a very clean surface, an exceptionally smooth hand-feel, and is highly resistant to pilling, making it a hallmark of high quality.

Mercerized Cotton:

This is a chemical finishing process, typically applied to high-quality combed cotton yarns or fabrics, that causes them to transform. By treating it with an alkaline solution, the cotton fibers swell and become rounder and more uniform. Mercerization imparts a significant silk-like luster, improves color vibrancy and fastness, and increases the fabric’s dimensional stability and strength.

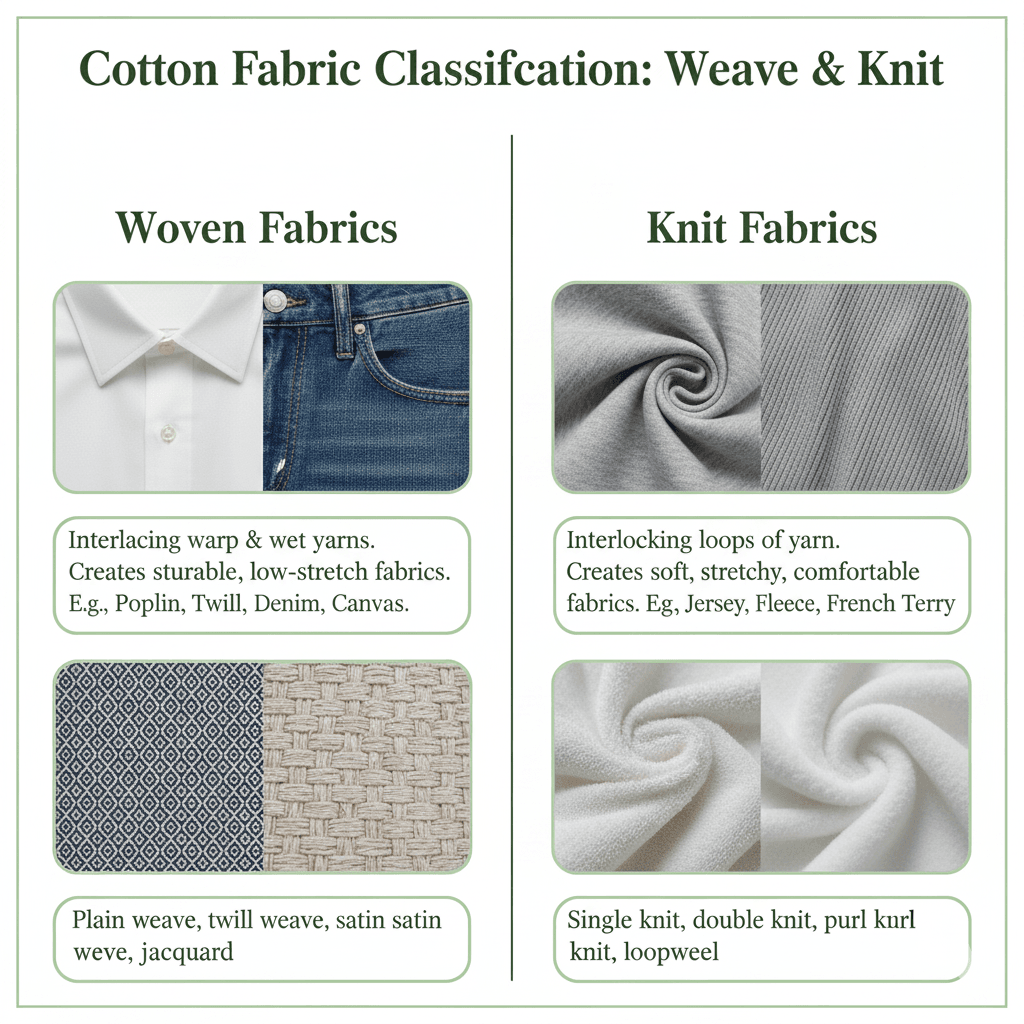

Classification by Weave/Knit

This is the key to a fabric’s final form, elasticity, and style.

Woven Fabrics:

Made by interlacing two sets of yarn (warp and weft) at right angles. The structure is stable and typically has no stretch. They tend to be crisp and structured. Common types include:

- Poplin: Tightly woven with a smooth, fine surface. The classic choice for dress shirts.

- Twill: Characterized by a diagonal rib pattern. It’s more durable and thicker than poplin; denim is the most famous example.

- Sateen: Has long floating yarns on the surface, creating a luxurious, satin-like sheen and a very soft feel. A top choice for premium bedding.

Knit Fabrics:

Formed by interlocking loops of a single yarn, similar to knitting a sweater. This structure gives knits natural stretch, softness, and comfort. They are ideal for casual and close-fitting garments. Common types include:

- Jersey: The most common knit fabric, used for T-shirts. It’s soft, breathable, and drapes well.

- Pique: Features a textured, waffle-like pattern that is more breathable and structured than jersey. The signature fabric for high-quality polo shirts.

From Wardrobe to Home: Cotton Fabric Uses

With a clear understanding of the categories, we can now match the right fabric to the right application.

What are the best cotton fabrics for apparel?

- High-End Dress Shirts: High-yarn-count combed poplin made from long-staple or fine-stapstaple cotton.

- Quality Casual T-Shirts: Combed jersey made from fine-staple cotton.

- Classic Polo Shirts: Breathable piqué knit made from fine-staple cotton.

- Jeans/Work Jackets: Durable heavyweight twill (denim) made from coarse-staple cotton.

- Luxury Pajamas/Robes: Exceptionally soft sateen or combed jersey made from long-staple cotton.

What are the advantages of cotton in home textiles?

In the home, cotton is beloved for its unparalleled comfort and safety. High-thread-count sateen made from long-staple or high-quality fine-staple cotton is the standard for five-star hotel bedding, providing a silky and healthy sleep experience. In the bathroom, the absorbency of cotton towels is superior to other fibers, with softness directly linked to the quality of the raw cotton.

Becoming a Smart Buyer: A Purchasing Guide for Novices

You now have all the core theoretical knowledge. The final step is to learn how to apply this knowledge to actual purchasing decisions, allowing you to choose with confidence.

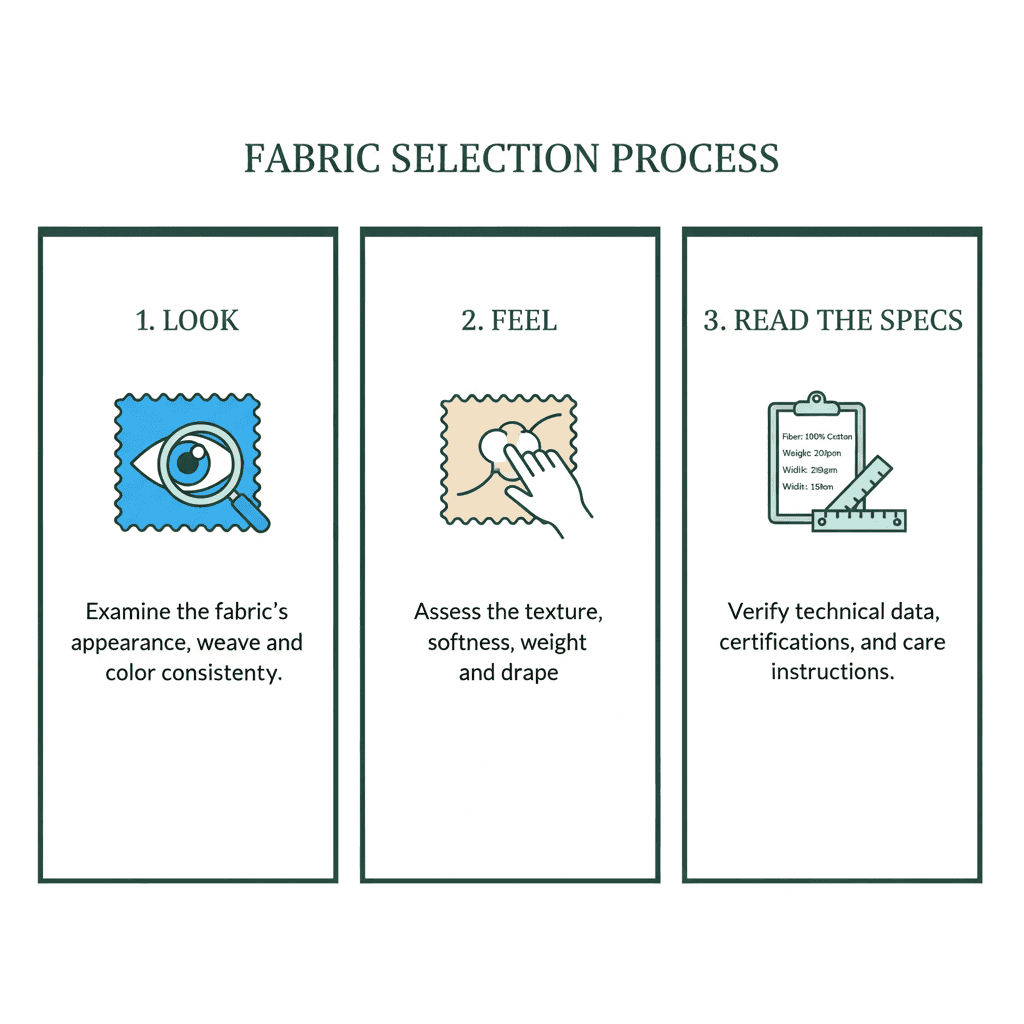

When faced with a piece of cotton fabric, how should I evaluate it?

When you get a sample, you can quickly assess its quality with a simple three-step process:

1. Look

Hold the fabric up to the light. Check for an even, clean surface, free of slubs, inconsistencies, or defects. Fabric made from longer fibers typically has a more natural, gentle luster.

2. Feel

Touch the fabric repeatedly with your palm and fingers. Assess its softness, smoothness, and thickness. Combed fabrics will feel noticeably smoother.

3. Read the Specs

This is key for objective information. Focus on the two metrics we’ll cover next: “Yarn Count” and “GSM.”

Understanding “Yarn Count” and “GSM”

Yarn Count and GSM are two of the most common objective metrics:

Yarn Count (S): Refers to the fineness of the yarn. A higher number means a finer yarn, resulting in a more delicate and smoother fabric that requires higher quality raw cotton.

GSM (Grams per Square Meter): Refers to the weight of the fabric. A higher number means a thicker and denser fabric, which is generally more durable and less transparent.

What key questions should I ask a supplier for the first time?

To sound professional and get all the necessary information, in addition to price and Minimum Order Quantity (MOQ), be sure to ask:

Raw Material Grade

What grade of cotton is used? (Long-staple / Fine-staple / Coarse-staple)

Yarn Process

Is it combed or carded? What is the yarn count?

Fabric Specs

What is the exact GSM and usable width?

Finishing Processes

Has it been mercerized or pre-shrunk?

Quality Standards

What are the shrinkage rate and color fastness standards?

Conclusion

We hope this detailed cotton fabric guide has served as a reliable companion on your journey. The core logic for selecting high-quality cotton fabric is simple:

1. First, define your purpose;

2. Then, understand the categories by material, process, and weave;

3. And finally, make an informed decision by interpreting the key specifications.

If you’re ready to start your next project, feel free to browse our product collections or contact our fabric consultants for professional service.

Frequently Asked Questions (FAQ)

1,What is the difference between Yarn Count and Thread Count?

Yarn Count and Thread Count (TC) are related but different concepts. Yarn Count describes the fineness of a single yarn (higher number = finer yarn). Thread Count, typically used for woven bedding, is the total number of yarns (warps and wefts) within one square inch of fabric.

You could say that a high yarn count is a prerequisite for achieving a high thread count, but they measure different things.

2,Does all 100% cotton fabric shrink?

Yes, shrinking is a natural characteristic of the cotton fiber. The fibers swell when wet and contract when they dry. However, high-quality fabrics are often pre-shrunk (a process called Sanforizing), which greatly minimizes the shrinkage in the final garment.

Care Tip:

To further reduce shrinking, it is best to wash in cold water and tumble dry on low heat or line dry.