🚢 Introduction: Why is proper storage of denim important?

In the global textile trade, the most expensive phone call a brand director or sourcing manager can receive isn’t about a raw material price increase—it’s about a logistics disaster.

(Factory Real Experience)

As a fabric supplier, the call I dread most is not about price negotiation, but about ‘catastrophe.’ I vividly remember a call from a client: a shipment of premium jeans worth $200,000 had spent 30 days at sea. Because of a minor leak in the container seal and uncontrolled internal humidity, 40% of the cargo arrived covered in white mildew, rendering it unsalvageable. That single incident wiped out the season’s profit margin.

This tragedy highlights a critical truth: Successful sourcing is only the starting point. Professional procurement management requires vigilance over every step after the product leaves the factory gate.

This guide is not a household laundry tip sheet; it is a professional manual for risk avoidance and inventory management. We will focus on two core missions:

- The B2B Storage Guide: How to scientifically protect your denim inventory in the warehouse and during logistics using data-driven methods.

- The B2B2C Care Guide: How to craft professional, legally compliant care labels to protect your end customer and your brand’s reputation.

(To understand why denim’s cotton fibers are so susceptible to environmental damage, read our foundational guide: what-is-denim-fabric)

📦 Part 1: The B2B Storage Guide (Protecting Your Inventory)

Once the fabric is delivered, it enters your custody. This is where it faces its first major risks. Scientific storage management is the only way to ensure your millions of dollars in inventory do not depreciate while sitting on the shelf.

⚠️ The 3 Great Enemies of Stored Denim

To defend your stock effectively, you must understand the enemy. The biological and chemical characteristics of raw cotton fiber and indigo dye expose your inventory to three primary threats:

💧 1. Moisture: The Invisible Destroyer

Cotton fiber is hydrophilic, meaning it aggressively absorbs moisture from the air. When the warehouse RH alert threshold textiles is breached—typically when Relative Humidity (RH) exceeds 65%—the cotton fabric becomes a fertile breeding ground for Mold and Mildew. This is not just surface dirt; it is a biological attack that degrades the cellulose fiber.

👖 2. Friction: The Cause of “Crocking”

Indigo dye has naturally poor indigo crocking test AATCC 8 results because the dye molecules sit on the surface of the yarn rather than penetrating the core. During transport and handling, constant vibration and stacking pressure cause deep indigo denim to rub against itself or adjacent light-colored items. This results in Crocking (color transfer), which can ruin hangtags, pocket linings, or even other garments in the same box, leading to a dye transfer complaint handling SOP.

☀️ 3. Light: The Source of Irreversible Fading

Indigo is highly light-sensitive. Prolonged exposure to sunlight or even strong fluorescent warehouse lighting causes the dye molecules to oxidize and break down. This results in UV exposure fading, often appearing as yellowed “shade bands” along the fold lines of fabric rolls. Once this happens, the fabric is often considered dead stock.

🏭 How to properly store denim rolls to prevent damage?

For fabric mills and garment factories, the storage of raw material rolls is the first line of defense. To prevent irreversible damage to your raw material, warehouse teams must follow this strict protocol:

Step 1: Establish Environmental Controls

Configure your warehouse HVAC system to maintain a specific denim storage temperature range of 15-25°C. Crucially, install industrial dehumidifiers to keep the best humidity for denim storage consistently below 60% RH. This is the primary defense against mold germination.

Step 2: Elevate the Inventory (No Floor Storage)

Never store fabric rolls directly on a concrete floor, as concrete wicks moisture from the earth into the fabric. You must utilize pallet storage for fabric rolls or heavy-duty racking systems. Ensure every roll is elevated at least 10-15cm off the ground to create an essential airflow buffer.

Step 3: Maintain Light-Proof Shielding

Indigo is sensitive to light oxidation. Ensure every roll retains its original black film wrap for denim rolls or opaque plastic packaging. If a roll is opened for sampling, it must be re-sealed immediately to ensure 100% protection from UV rays and fluorescent warehouse lighting.

Step 4: Enforce FIFO Rotation

Denim is organic; it ages. Strictly enforce a FIFO inventory for textiles (First-In, First-Out) management system. Organize your racking so that older stock is easily accessible. Aim to use or ship fabric within 6-12 months to prevent yellowing (oxidation) or the degradation of elastane fibers in stretch denim.

📊 (In-House Data & Experience)

In our own warehouse, we don’t guess; we measure. We install 2 humidity data logger for warehouse units on every stack of fabric rolls.

Last rainy season, we had a batch of 12 tons of deep indigo denim. The data loggers revealed a critical insight: in the bay where the nighttime RH peaked at 68%, we found slight mildew spots developing on the paper tube ends by day 6. In contrast, in the bay where the RH peak was controlled at 58%, the rolls remained perfectly clean.

Since then, we treat “nighttime peaks” as our red-line management metric, not just daily averages. We also replaced all low-level solid shelving with perforated decks to improve vertical airflow. The results were immediate.

🧥 How to Store Finished Denim Garments

Once the fabric is cut and sewn, the value density increases, and so does the risk. You are now protecting a finished asset.

1. Preventing Mold in Cartons

📉 Technical Benchmark: The Threshold for Mold

Preventing mold growth is paramount. White papers on AATCC 30 antifungal test textiles from authoritative testing bodies like SGS indicate that mold grows exponentially on cotton fabrics at humidity levels above 65% and temperatures above 25°C.

✅ The Solution: Scientific Desiccant Use

Place a sufficient amount of desiccant for clothing storage (silica gel or clay) in every carton. Do not guess; use a container desiccant calculation textile formula based on carton volume and shipping duration.

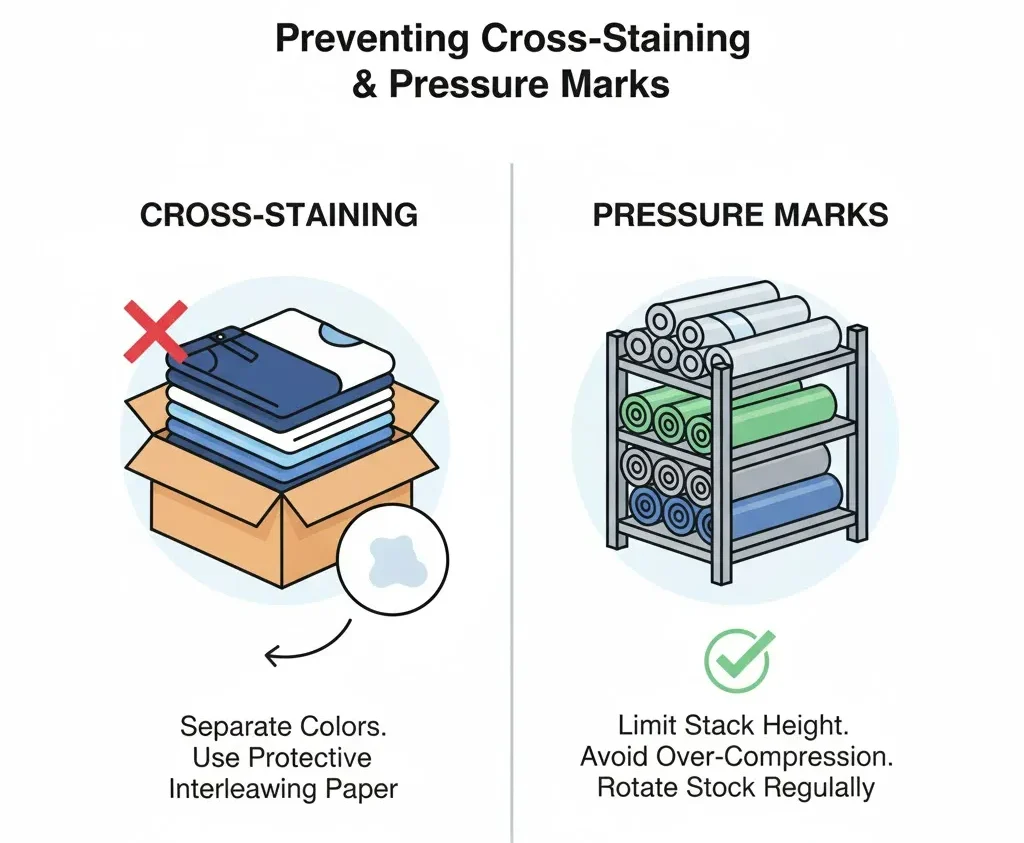

2. Preventing Cross-Staining & Pressure Marks

✅ The Solution: Packaging Protocol

- Independent Packaging: Use an individual polybag with vents for every single garment. This is the only sure way to prevent indigo dye bleeding and cross-staining between garments in the same box.

- No Compression: Do not over-compress cartons to save shipping space. Carton compression damage denim increases internal pressure, which exacerbates friction and leads to permanent “pressure marks” or crocking lines on the fold.

⚠️ From the Field: The Costly “Container Rain” Lesson

A high-end retailer we know faced a logistics disaster when their shipment of Fall/Winter denim jackets suffered from “Container Rain.” Due to a lack of desiccants and a sudden temperature drop at sea, condensation formed on the container roof and rained down on the cartons.

Because the cartons were not lined with waterproof sheets, the moisture penetrated. The entire batch arrived at the port with visible mold spots. They had to undertake a massive mildew on denim removal warehouse claim process, involving professional ozone cleaning and repackaging. This resulted in a 15% direct cost increase and missed delivery deadlines.

In our risk management protocol, mildew and shade variation caused by improper storage are considered the most regrettable form of denim-fabric-defects-guide (warehouse loss) because they are 100% preventable.

🏷️ Part 2: The B2B2C Care Guide (Protecting Your Customer & Brand)

Your responsibility doesn’t end at the warehouse loading dock; it extends to educating your end consumer. An incorrect or vague Care Label is the second leading cause of customer complaints and returns (after fit).

1. Why Your Care Label is a Legal & Brand Protection Tool

The types-of-denim-washing determines the final aesthetic, but the care label protects that aesthetic.

- Legal Risk: In the USA, the FTC (Federal Trade Commission) Care Labeling Rule mandates that manufacturers must provide accurate, complete care instructions backed by a “reasonable basis” (testing). In Europe, ISO 3758 (Textile Care Labeling Code) is the standard. Providing incorrect care label wording is a liability.

- Brand Protection: If a customer ruins their jeans because you didn’t warn them about shrinkage, they blame your brand quality, not their laundry habits.

2. Mandatory Instructions for RAW DENIM

This section addresses the how to wash raw denim queries. Since raw denim is unique (stiff, shrinks, bleeds), standard instructions are insufficient.

⚠️ The Bleeding Warning

You must manage expectations about color transfer.

Why: This protects you against dye transfer complaint handling SOP issues.

📏 The Shrinkage Warning

Address does raw denim shrink directly.

🧼 The Method

3. Mandatory Instructions for Washed & Stretch Denim

This category, often containing elastane, is the most frequently ruined by consumers using heat.

🌊 Washing & Drying

Why: Cold water minimizes fading and prevents denim color transfer to other clothes.

🚫 The Critical Prohibition

Why: This is the answer to heat damage elastane jeans. High heat destroys the elastane fibers, causing the jeans to lose their recovery and “bag out” at the knees. This instruction is vital for reducing returns on stretch denim fabric products.

(To understand the fundamental difference between raw and washed denim as they leave the factory, and why their care needs differ, read our guide on how-raw-denim-becomes-washed-denim-proces.)

🏁 Conclusion: Your Responsibility Extends Beyond the PO

Professional denim brands excel not just in sourcing, but in the entire lifecycle management of the product. Scientific warehousing protects your profit margins from invisible threats like humidity, while accurate care guides protect your brand reputation from preventable consumer errors.

📝 Summary

Protecting your denim investment requires a systematic process: from warehouse RH alert threshold textiles management to anti-friction packaging, and finally to legally compliant care labels.

🚀 Call to Action

We provide more than just top-tier fabric; we offer full-chain technical support. To understand how we control quality from the very source, read our denim fabric sourcing guide.

If you face challenges with storage damage, mold prevention, or drafting compliant care labels for your market, contact-us today. Our supply chain experts are ready to consult with you.

❓ FAQ (Frequently Asked Questions)

What is the ideal humidity for a denim warehouse?

The best humidity for denim storage is consistently below 60% RH (Relative Humidity). Once humidity exceeds 65%, the risk of mold germination increases dramatically. We recommend using industrial dehumidifiers and installing digital humidity data logger for warehouse systems for constant, 24/7 monitoring of micro-climates within the racks.

How to prevent raw denim from bleeding/crocking?

You cannot stop the bleeding completely, as it is a natural characteristic of indigo dye. However, you can control it. The most effective method to recommend to customers is a cold soak raw denim (before wearing) to wash out excess surface dye and starch. Always advise the customer to wash the garment inside-out, separately, in cold water, and air dry. This minimizes indigo crocking and protects other garments.

How to maintain the freshness of raw denim jeans without washing?

Since raw denim enthusiasts often avoid washing for months to achieve high-contrast fade patterns, odor can be an issue. The best method to combat odor build-up without water is temperature control. Instruct consumers to turn the jeans inside-out and place them in a sealed plastic bag in the freezer for 24-48 hours. This process kills most odor-causing bacteria without affecting the fit, the indigo color, or the rigid hand-feel.

How to store finished garments to prevent cross-staining?

Friction is the enemy. During shipping, vibrations cause garments to rub against each other. The best practice is to individually poly-bag each deep indigo or dark garment before boxing. This creates a physical barrier that prevents the loose dye from rubbing onto adjacent light-colored seams, hangtags, or garments during movement and shipping.

Can I dry clean denim jeans?

We do not recommend it. Dry cleaning solvents (like perchloroethylene) can strip the natural oils from the indigo dye and the cotton fiber itself. This can make the fade look flat and uninteresting (“chemical fade”) and leave the fabric feeling stiff and dry. Your care label should always recommend Wet Clean (Water Wash) to maintain the authentic character of the denim.