🏭 The Cost of Vague Specs: A Factory Manager’s 20-Year Lesson

1. Blueprints vs. Lottery Tickets

In my 20 years managing textile production, I’ve seen thousands of purchase orders land on my desk. Some are meticulously detailed “blueprints” that leave no room for error. Others—too many, unfortunately—are vague “lottery tickets.”

2. The “Lottery Ticket” PO

Early in my career, I received exactly such an order from a mid-sized European fashion brand:

Color: White.

Quality: High.

Quantity: 5000m.

3. The Gap Between Expectation & Spec

They wanted “High Quality” white poplin for a summer shirt. We supplied a standard 133×72 40s poplin, the most common spec in the market. When the bulk arrived, they rejected it instantly.

- ❌“It’s too see-through!” they claimed.

- ❌“And it feels too crisp; we wanted soft!”

The problem wasn’t our fabric; it was the gap between their subjective expectation and their objective specification.

4. Locking in the Variables

We sat down with their sourcing team and explained: “High quality” is subjective.

- Solution A: If you wanted opacity, we needed a higher yarn count or density.

- Solution B: If you wanted softness, we needed a specific finish like Liquid Ammonia.

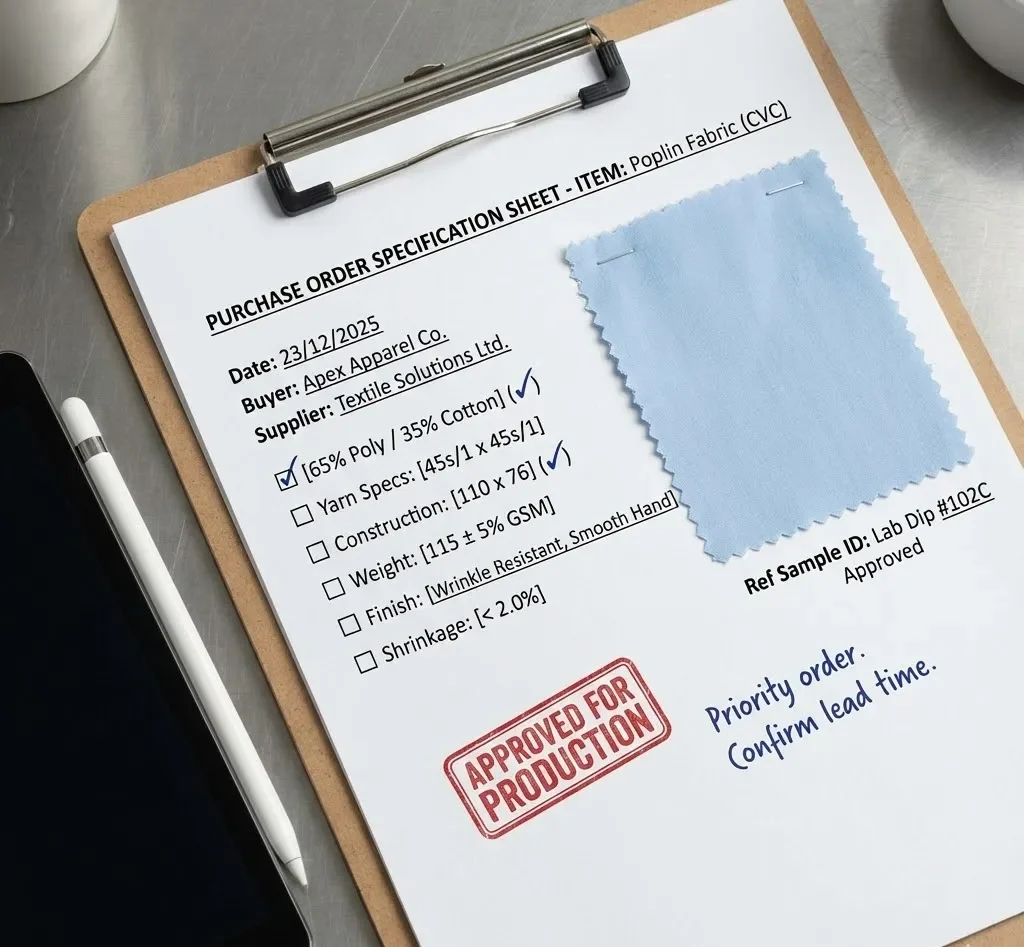

We reworked the order, rewriting their PO spec for Poplin Fabric together to lock in every variable. That brand is now one of our most stable partners, and their POs are now rigorous technical documents.

Note: we voluntarily bore the losses of the first batch of goods, and the customer appreciated our sincerity. Because of this, they have maintained a close working relationship with us to this day.

💡 Why I Wrote This Guide

This guide is the result of those hard-learned lessons. Whether you are sourcing for dress shirts, uniforms, or home textiles, I will teach you how to write a poplin PO spec that protects your brand, prevents disputes, and ensures the factory delivers exactly what you approved.

📄 What Is a Poplin Order Specification Sheet?

1. The Definition

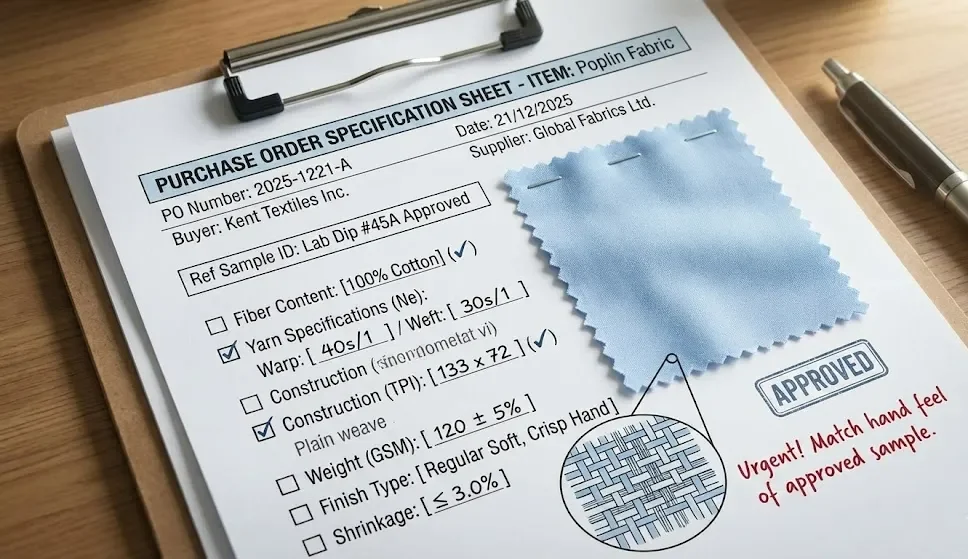

A poplin PO spec is a purchasing document that locks down fiber content, construction, GSM/width tolerances, finishing, shrinkage & colorfastness targets, inspection standard, and shade control—so bulk production matches your sample.

- 🌉It acts as the legal and technical bridge between your design concept and the factory’s loom.

- 🛠️How to build it: Start from the end-use (shirt/uniform/lining) → Specify construction + tolerances + tests + approvals in a copy-paste checklist.

2. Why Is It Critical?

Without a poplin fabric specification sheet, “quality” is just an opinion. With one, it is a measurable contract.

- ✅ With Spec: If the fabric shrinks 5% but your PO says “Max 3%,” you have grounds for a claim.

- ❌ Without Spec: If your PO is silent, the factory’s standard (which might be 5%) applies, and you have no recourse.

⚠️ What Makes Poplin Specs “Tricky”?

Before we dive into how to write poplin fabric specifications, you need to understand why poplin disputes happen in the first place.

1. Poplin Is Not One Fixed Fabric

Why poplin specs are tricky is that Poplin is a broad family, not a specific item. A US buyer might call a heavy 150gsm plain weave Poplin, while a UK supplier calls it Canvas.

- 🔄Variations: Differences come from yarn count, density, finishing (soft vs. crisp), and dyeing route (Continuous vs. Jig).

- ⚠️The Risk: If you don’t define the poplin fabric construction, the factory will use the most economical yarn and density that technically qualifies as “poplin,” leading to handfeel issues or white poplin opacity problems.

2. Most Disputes Come from Missing Tolerances + Test Method

Writing High Quality or Good Colorfastness is useless.

A factory might test shrinkage using a “Line Dry” method (which shrinks less), while your lab uses “Tumble Dry” (which shrinks more).

You must specify the tolerance (e.g., ±3%) and the test method (e.g., AATCC 135). Without these, you are speaking different languages.

🎯 Step 1 — Start with End-Use (Your Strategy)

Before filling out the poplin fabric spec sheet template, define your goal. Different end-uses require different priority specs.

| End-Use | Priority Specs | Critical Risks to Lock |

|---|---|---|

| Dress Shirt Poplin | Handfeel, Opacity, Smoothness | White poplin opacity spec, Wrinkling, Pilling |

| Uniform/Workwear | Durability, Colorfastness, Strength | Colorfastness to rubbing, Abrasion resistance |

| Lining/Medical | Stability, Cleanliness, Cost | Fabric width tolerance, Skewing, Dimensional stability |

| Printing Poplin | Absorbency, Whiteness, Stability | Strike-off approval, Print penetration, Shrinkage |

Not sure which type fits?

Read our Poplin Shirting Specs Guide

🧬 Step 2 — Write the Core Identity (Locking the DNA)

These four lines in your poplin fabric order specification sheet define exactly what the factory must weave. If these are wrong, no amount of finishing can fix it.

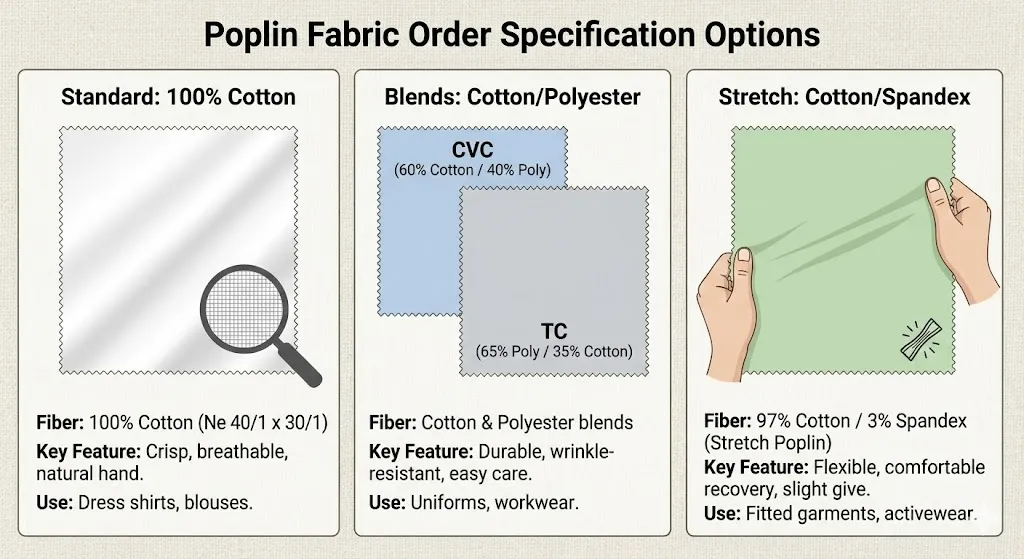

1. Fiber Content

- Standard: 100% Cotton

- Blends: 60% Cotton / 40% Polyester (CVC), 65% Polyester / 35% Cotton (TC).

- Stretch: 97% Cotton / 3% Spandex (stretch poplin specification).

📝 Note: Always include the fiber content tolerance (e.g., ±3% is standard, but some markets require 0 tolerance for labeling).

2. Weave

- ✔ Correct: Plain Weave (Poplin Construction)

- ✘ Wrong: Just Poplin Fabric (too vague).

3. Construction (The DNA)

- Format: Yarn count and density for poplin.

- Example: 40s x 40s / 133 x 72 (Warp x Weft / EPI x PPI).

Why: This locks the poplin fabric density and poplin fabric construction. It prevents the factory from using cheaper, coarser yarns.

4. Finish

Options: Mercerized (for shine), Sanforized (for shrinkage control), Peached (for softness), Wrinkle-Free (Resin).

Impact: A mercerized poplin specification creates a completely different fabric than a standard “Soft Finish” poplin.

📊 Step 3 — Key Specs Table (The Core Data)

This table is the heart of your poplin purchase order specification. Copy this structure directly into your tech pack.

| Spec Item | What to Write in PO | Buyer Notes (Risk Control) |

|---|---|---|

| Fiber Content | Shell: __% __ / __% __ | Blends need tolerance (e.g., ±3%) |

| Weave | Plain Weave (Poplin) | Don’t just write Poplin |

| Yarn Count | Warp: __, Weft: __ | Define yarn type: Combed/Carded/Compact |

| Density | EPI/PPI (e.g., 133/72) | Determines opacity vs GSM vs yarn count poplin |

| Weight | __ GSM (Tolerance ± 5%) | Fabric GSM tolerance is critical for yield |

| Width | __ cm/inch (Usable Width) | Fabric width tolerance (-0/+2cm) prevents cutting loss |

| Finish | Mercerized / Sanforized / Resin | Finish affects shrinkage/hand/color |

| Color | Lab dip approval required | Dark colors need strict rubbing spec |

| Shrinkage | ≤__% Warp/Weft (Method Specified) | Must specify wash method (Home/Industrial) |

| Inspection | 4-Point System, Max 20pts/100yd | Define fabric defect classification clearly |

🧪 Step 4 — Performance Specs (The “Pass/Fail” Rules)

This section tells the factory how the fabric must behave. Use the “Indicator + Standard + Minimum Grade” format.

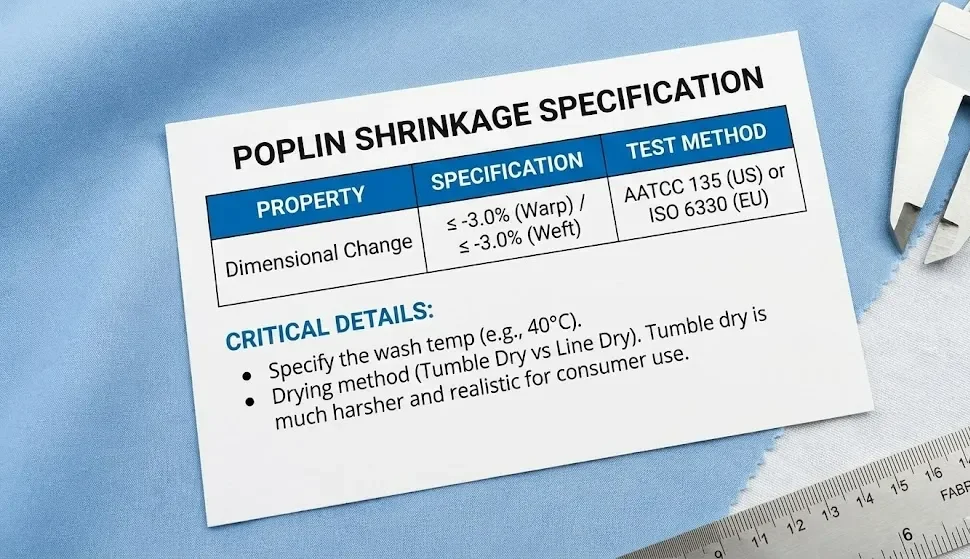

1. Shrinkage (Dimensional Stability)

How to specify poplin shrinkage:

- Spec: Dimensional Change: ≤ -3.0% (Warp) / ≤ -3.0% (Weft)

- Test Method: AATCC 135 (US) or ISO 6330 (EU).

- Critical Details: Specify the wash temp (e.g., 40°C) and drying method (Tumble Dry vs Line Dry). Tumble dry is much harsher and realistic for consumer use.

📢 Industry Standard: According to ISO standard 5077 for fabric dimensional change, testing must replicate the care label instructions. Specifying a test method like ISO 6330 ensures that “3% shrinkage” means the same thing in your lab as it does in the factory’s lab.

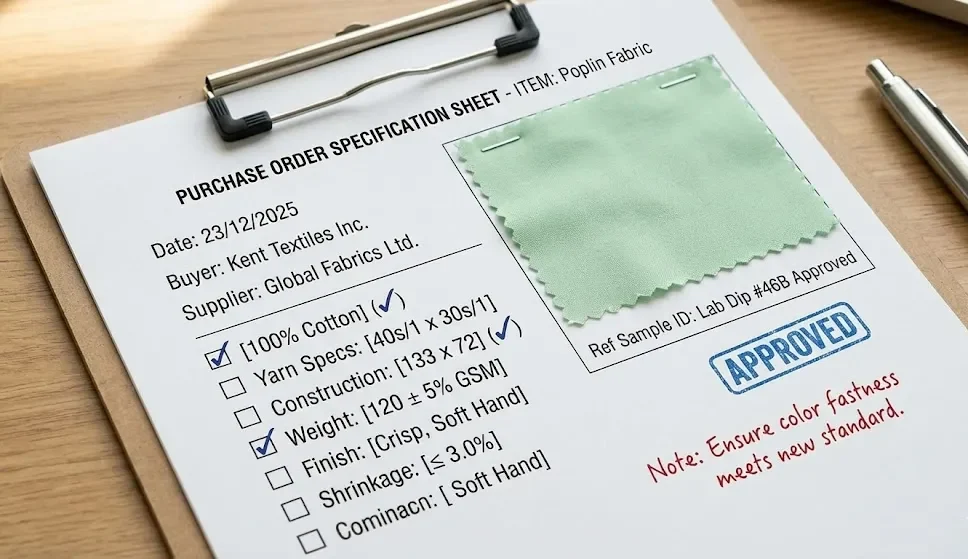

2. Colorfastness (Wash / Rub / Perspiration / Light)

Colorfastness requirements for poplin shirts:

- 🧼 Washing: ≥ Grade 4.0 (AATCC 61 / ISO 105-C06)

- 🖐️ Crocking: Dry ≥ 4.0 / Wet ≥ 3.0 (AATCC 8 / ISO 105-X12)

Note: For dark poplin (Navy/Black/Red), Wet Crocking 3.0 is a strict but necessary standard to avoid staining white pants. - 💧 Perspiration: ≥ Grade 4.0 (ISO 105-E04)

Note: Critical for dress shirts in the armpit area. - ☀️ Light: ≥ Grade 4.0 (ISO 105-B02)

Note: Important for uniforms worn outdoors.

3. Pilling / Abrasion (Durability)

Poplin pilling resistance requirement:

- 🧶 Pilling: Pilling Resistance: ≥ Grade 3.5 (ISO 12945 / ASTM D3512)

- 🛡️ Abrasion: Abrasion Resistance: ≥ 20,000 Cycles (Martindale ISO 12947)

💡 Note: Abrasion is vital for uniform/workwear poplin but less critical for dress shirts.

Learn more about these tests in our guide:

Colorfastness to Crocking Guide

🎨 Step 5 — Shade Control & Approvals (Avoiding the “Bulk Disaster”)

This is the most practical B2B module. Color variation is the reason for bulk rejection.

1. Lab Dip / Strike-Off

- 🧪 Requirement: Lab dip approval required before bulk dyeing.

- 🖨️ Printing: Strike-off approval required before bulk printing.

🛑 Action: Never authorize bulk production based on a digital file. You must sign off on physical fabric to check shade and print penetration.

2. Bulk Approvals (PPS / TOP)

- ✂️ PPS (Pre-Production Sample): PPS approval required before bulk cutting.

(What is it: A sample from the actual bulk fabric roll. Use this to verify handfeel and finish.) - 📦 TOP (Top of Production): TOP sample approval required before shipment.

(What is it: A garment or fabric piece taken from the final packed goods. Use this to verify packaging and final quality.)

3. Lot Control

- 🔒Clause: No mixing dye lots in one shipment (unless approved in writing).

- 🌈Shade Banding: Submit shade band for approval.

(Explanation: A card showing the color variation within the bulk: Lightest – Standard – Darkest. You approve the range.) - 💻Delta E: ΔEcmc < 1.0 (Digital color tolerance).

👮♂️ Step 6 — Quality Standard & Defect Rules (The Referee)

When you inspect the goods, what rules apply?

1. Inspection Standard

- 📏System: Inspection: 4-Point System (ASTM D5430)

- 🛑Limit: Max Points: 20 points / 100 sq yd (Standard for high-quality shirting).

- 🔍Sampling: AQL 2.5 (if using garment sampling logic).

2. Common Poplin Defects You Should Name in PO

Listing specific defects tells the QC what to hunt for:

- ❌ Barre / Shade Streak: Horizontal lines caused by yarn variation.

- ❌ Weft Slub / Thick-Thin Yarn: Lumps in the yarn that ruin the smooth poplin face.

- ❌ Bow / Skew: Distortion of the weft yarns (critical for stretch poplin).

- ❌ Oil Stain: From high-speed looms.

- ❌ Reed Mark: Vertical gaps from loom tension issues.

- ❌ Uneven Finish: “Harsh handfeel” due to poor softening application.

Visualize these defects in our guide:

Common Poplin Fabric Defects Guide

(Note: Poplin shares many defects with denim)

📝 Poplin PO Spec Sheet Template

Use this poplin fabric spec sheet template as your “Ultimate Deliverable.”

| Section Category | Specification Details |

|---|---|

| 1) Product / End-use |

|

| 2) Fiber Content |

|

| 3) Construction |

|

| 4) Weight & Width |

|

| 5) Finishing |

|

| 6) Dimensional Stability |

|

| 7) Colorfastness (minimums) |

|

| 8) Pilling / Abrasion |

|

| 9) Shade Control & Approvals |

|

| 10) Inspection & Defects |

|

| 11) Packaging & Marking |

|

| 12) Compliance (if required) |

|

⚠️ Common Mistakes When Writing a Poplin PO (The Pitfalls)

Even experienced buyers make these errors. Avoid them to ensure your poplin fabric sourcing specification is bulletproof.

1. Only writing “Poplin” without Construction

💥 Result: Factory uses coarse carded yarns and lowers the density to save cost. The fabric feels rough and cheap.

2. Writing GSM/Width without Tolerance

💥 Result: You get 56″ width instead of 58″, increasing your marker consumption and fabric waste.

3. Writing Shrinkage without Method

💥 Result: Factory tests with Line Dry (Passes). You test with Tumble Dry (Fails). You have no grounds to claim because the method wasn’t agreed upon.

4. Skipping Lab Dip / Shade Control

💥 Result: How to avoid shade variation in poplin bulk? Never skip this. Without a standard, Navy Blue can arrive as Purple Blue.

5. Specifying High Count without Measurable Metrics

💥 Result: High Count is marketing. “144×80” is engineering. Always use numbers that a QC inspector can measure.

🎯 Conclusion

1. More Than Paperwork

A poplin PO spec is not just paperwork; it is your product’s insurance policy.

2. Why We Love Detailed POs

In our factory, we love detailed POs. Why? Because a clear poplin fabric specification sheet removes the guesswork.

- ✅ It tells my weaving manager exactly which beam to warp.

- ✅ It tells my dyeing manager exactly which recipe to use.

- ✅ It tells my QC manager exactly what to reject.

3. From Buyer to Partner

By starting with the end-use, locking down the construction, defining the tolerances, and enforcing the test methods, you transform from a buyer into a technical partner.

Ready to lock in your poplin quality?

❓ FAQ: Common Questions on Poplin PO Specs

Q1: What is a realistic GSM tolerance for bulk poplin?

For standard cotton poplin, the industry standard tolerance is ± 5%. For example, if you order 120 GSM, any roll between 114 GSM and 126 GSM is considered acceptable.

🏭 Factory Note: Setting a tolerance tighter than 3% is risky for poplin because the finishing process (like mercerization or preshrinking) can slightly alter weight without affecting quality. Always specify this range in your poplin fabric quality agreement.

Q2: Which shrinkage test method should I use for poplin: AATCC or ISO?

It depends on your target market, but the key is consistency.

- 🇺🇸 US Market: Use AATCC 135. Be sure to specify the drying cycle (e.g., “Tumble Dry Low”) because tumble drying causes more shrinkage than line drying.

- 🇪🇺 EU/Asia Market: Use ISO 6330.

Why it matters: Why poplin disputes happen is often because the buyer tests with a harsh dryer while the factory tests with gentle line drying. Locking the method prevents this.

Q3: What is the difference between Lab Dip and Strike-Off approval?

These are both pre-production color approvals, but for different methods.

- 🧪 Lab Dip: Used for Solid Dyed poplin. It is a small swatch dyed in a beaker to match your Pantone standard.

- 🖨️ Strike-Off: Used for Printing Poplin. It is a sample of the actual print pattern on the fabric to check design registration, color, and penetration.

✅ PO Requirement: Your PO must state: “Bulk production cannot proceed without signed Lab Dip/Strike-Off approval.”

Q4: What is a “Shade Band” in fabric dyeing?

A shade band is a set of fabric swatches cut from the bulk production that shows the full range of color variation within that lot (e.g., Lightest acceptable, Standard, Darkest acceptable).

💡 Why you need it: How to avoid shade variation in poplin bulk? By approving a shade band before the goods ship. This ensures you don’t receive rolls that look like different colors when sewn together.

Q5: What is the difference between PPS and TOP samples?

- PPS (Pre-Production Sample): Fabric taken from the start of the bulk finishing. You approve this before the factory cuts the sewing markers.

- TOP (Top of Production): Finished goods or fabric taken from the final packed shipment. You approve this to verify that the packing and final quality match the PPS.

📦 Sourcing Tip: Always withhold final payment until the TOP sample approval is signed.

Q6: How do I specify opacity for white poplin shirts?

To avoid white poplin opacity issues (see-through fabric), do not just write “High Opacity.”

- ✔ Correct Spec: Specify a higher density construction (e.g., 144×80 instead of 133×72) or use 80s/2 ply yarns.

- ✔ Test: Add a clause: “Must pass opacity test against standard black/white grid card.”

Q7: Can I use the same PO spec for Dress Shirts and Uniforms?

No.

- 👔 Dress Shirt Poplin: Prioritizes handfeel (Mercerized), whiteness, and appearance.

- 👷 Uniform/Workwear Poplin: Prioritizes durability. You must add Abrasion Resistance (Martindale >20,000 cycles) and Pilling specs, which are less critical for occasional-wear dress shirts.

Q8: What inspection standard should I cite in the PO?

The most widely accepted standard is the 4-Point System (ASTM D5430).

- 🎯 Typical Target: For first-quality shirting poplin, set the limit at Max 20 points per 100 linear yards.

- 📝 Defects to Name: Explicitly list Barre, Weft Slubs, and Oil Stains as “Major Defects” in your poplin fabric QC checklist.