🧥 Introduction: The Flannel Fallacy

1. The Hidden Trap

In my 20 years of textile manufacturing, I have seen the “Flannel Season” make or break fashion brands. But the biggest mistake I see buyers make isn’t about the plaid pattern or the color—it’s about the fiber composition.

2. A Real-World Lesson ($$$ Mistake)

I once had a client order 50,000 yards of “Heavyweight Flannel” for a winter shirt program. They chose 100% Polyester Flannel to save $0.50 per yard.

The shirts were incredibly warm, yes, but they trapped sweat like a plastic bag and pilled after three washes. The returns rate nearly killed their season.

3. So, what is the difference?

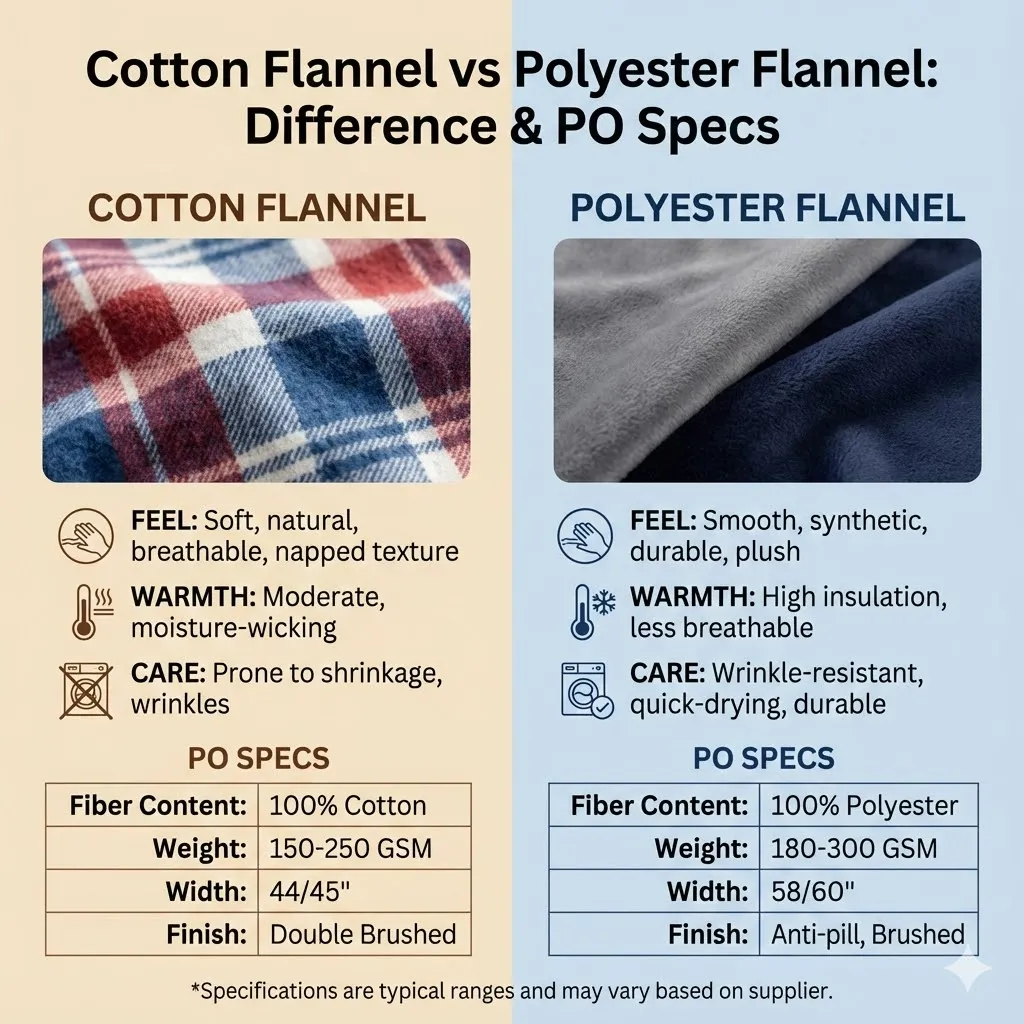

In short:

- ☁️ Cotton Flannel: Is breathable, soft, and improves with age, making it ideal for shirts and premium bedding.

- 🔥 Polyester Flannel: Is cheaper, more durable, and traps more heat, making it better for blankets, outerwear, and budget-friendly uniforms.

📘 Your Factory-Floor Manual

This guide is your technical manual. We will move beyond the basics to compare pilling risks, shrinkage specs, and printing capabilities, giving you the exact PO templates you need to source safely.

☁️ What Is Cotton Flannel?

1. The Definition

Cotton flannel is a woven fabric, typically plain or twill weave, made from cotton yarns that are brushed (napped) on one or both sides to raise fine fibers for a soft, fuzzy handfeel.

2. Common Specs

Usually ranges from 130 GSM (Lightweight) to 300+ GSM (Heavyweight).

3. The Key: Why it Works

The fuzz creates air pockets that trap body heat, but the cotton core allows moisture to escape.

🔥 What Is Polyester Flannel?

1. The Definition

Polyester flannel is a synthetic fabric made from polyethylene terephthalate (PET) fibers, often knit or woven, which is mechanically brushed to create a thick, plush pile that mimics wool or cotton.

2. Common Specs

Ranges from 150 GSM (Micro-fleece style) to 400 GSM (Blanket weight).

3. The Key: Plastic & Heat

It is essentially plastic spun into yarn. It is hydrophobic (repels water) and retains heat aggressively.

🧶 Composition & Structure: How They Are Made

1. Fiber Content

Typically 100% cotton, sometimes blends.

Typically 100% polyester (filament or spun), sometimes blended.

Two suppliers can both say “flannel,” but one is a lightly brushed plain weave for shirts, and another is a heavy high-loft brushed fabric for blankets. If you don’t lock construction + brushing level + weight range, you’ll get a different handfeel in bulk.

2. Weave & Knit Structure

- Cotton Flannel: Usually plain weave for classic shirts; sometimes twill for a stronger, slightly heavier feel.

- Polyester Flannel: Can be woven or knit. Knits often feel stretchier and bulkier, but may pill more.

3. Finishes That Change Performance

“You cannot just buy greige. You buy the finish.”

- Sanforizing: To stop shrinking.

- Mercerizing: For strength and luster.

- Anti-Static: To stop clinging.

- Anti-Pilling: Crucial for spun poly.

🚨 Factory Floor Warning

Many buyers send us a swatch of “Super Soft Poly Flannel” and ask us to match it with Cotton. It’s physically impossible.

Polyester can be brushed into a “high pile” (like fur). Cotton brushing is always lower and flatter. Don’t confuse the two textures.

⚖️ Cotton Flannel vs Polyester Flannel — Quick Answer

| Field | Cotton Flannel | Polyester Flannel |

|---|---|---|

| Best for | Pajamas, shirts, baby/kids wear, breathable bedding | Low-cost warm loungewear, blanket throws, lining, cold-weather items |

| Feel/Look | Natural soft, “cozy” hand; matte | Can be very soft too; sometimes slightly slicker or more “fuzzy” look |

| Breathability | Higher (better heat comfort) | Lower unless open structure; may feel warmer/hotter |

| Shrinkage risk | Medium (needs pre-shrink control) | Low (but heat distortion possible) |

| Wrinkle resistance | Medium–low | High |

| Pilling risk | Low–medium (depends on fiber length & brushing) | Medium–high (especially very fuzzy, low-twist surfaces) |

| Colorfastness risk points | Reactive/vat wash fastness usually stable; darker shades need crocking control | Disperse dye risks: rubbing + heat-related migration/sublimation in some processes |

| Printability | Very good: DTG/screen/reactive printing common | Great for sublimation (if 100% poly), also screen/pigment possible |

| Cost level | Medium | Often lower (varies by microfiber/yarn/finish) |

| Lead time / MOQ | Custom color/finish = moderate MOQ; greige/stock often faster | Stock polyester flannel often easier; special yarn/anti-pilling may raise MOQ |

| Factory note | Write shrinkage + handfeel + nap direction into the PO | Write pilling grade + anti-static + heat limits into the PO |

✋ Handfeel & Appearance: What You’ll Notice

1. Surface Texture

- ☁️ Cotton Flannel: Soft, matte, natural fiber “dry hand,” often feels less “static-y.”

- 🔥 Polyester Flannel: Can be extremely plush; sometimes feels slightly slick underneath the fuzz depending on yarn/finish.

2. Drape & Stiffness

- ☁️ Cotton Flannel: Flannel usually has a natural drape; heavier ones feel structured.

- 🔥 Polyester Flannel: Can feel lofty (more body) or slippery drape depending on knit vs woven and microfiber vs regular.

3. Opacity (See-Through Risk)

- ☁️ Cotton Flannel: Shirt-weight flannel is generally opaque enough, but light colors in light GSM may show through.

- 🔥 Polyester Flannel: Flannel for lining can be thin—if you’re using it for shirts, specify opacity expectations.

4. Noise / “Crisp” Level

- ☁️ Cotton Flannel: Tends to be quieter and “softer sounding.”

- 🔥 Polyester Flannel: Some constructions can have a slight “swish” or crispness (more noticeable in lighter weights or certain weaves).

⚖️ Performance Comparison (Breathability / Shrink / Pill / Fade)

1. Breathability & Heat Comfort

Cotton flannel is usually more comfortable in warm indoor environments; Polyester flannel feels warmer but can trap heat.

Cotton absorbs moisture and releases it; polyester doesn’t absorb much, so comfort relies more on structure and finishes.

- Pajamas, kidswear, bedding: Favor Cotton.

- Cold climates / Outer layers / Lining: Polyester can be better.

2. Shrinkage & Dimensional Stability (Wash/Heat)

Cotton flannel has higher wash shrinkage risk; Polyester flannel has lower wash shrinkage but is heat-sensitive.

Cotton fibers swell and relax in laundering; polyester can distort under high heat/pressing.

If you need stable sizing with minimal shrink complaints, polyester is easier—unless your customers use high-heat drying/ironing.

3. Pilling & Abrasion

Polyester Flannel is more likely to pill if you chase ultra-fuzzy softness; Cotton Flannel can pill too, but usually less if fiber/yarn is good.

Fuzzy surfaces + weak surface fibers + friction = pills. Polyester pills can be more visible and “harder” pills.

For high-friction areas (pants seat, cuffs), demand a pilling grade requirement and consider anti-pilling finish.

4. Colorfastness (Wash / Rub / Light / Chlorine)

Both can be stable, but risk points differ:

- Cotton Flannel: Dark shades need wet rubbing control and proper wash fastness spec.

- Polyester Flannel: Disperse dye can face heat-related migration/sublimation in some workflows (especially if heat pressing, transfers, or high-temp finishing).

If your product includes heat processes (heat press labels, sublimation printing), Polyester Flannel needs extra heatfast controls.

5. Wrinkle & Recovery

Polyester Flannel is easier care and less wrinkly; Cotton Flannel wrinkles more.

If you sell “no-iron / travel friendly,” polyester is the safer base.

6. Strength & Tear (Workwear vs Fashion)

Polyester Flannel typically has higher strength-for-weight; Cotton Flannel can be strong but depends on yarn and weave.

For heavy duty abrasion, specify abrasion/tear tests and let data decide—not fiber stereotypes.

🧭 Use-Case Guide: Choose Cotton Flannel or Polyester Flannel For Your End Product

Use this decision table to map your product to the right fabric.

| End-Use Product | Recommended Fabric | Recommended Spec | Risk Warning |

|---|---|---|---|

| Mens Plaid Shirt | 100% Cotton | 150-180 GSM Twill | Must control shrinkage <3% |

| Workwear Shirt | 65/35 TC Blend | 200 GSM Heavy | Balance durability vs. spark risk (poly melts) |

| Winter Pyjamas | 100% Cotton | 130 GSM Plain | Poly pyjamas cause “night sweats” |

| Promo Blanket | 100% Polyester | 280 GSM Knit | Static electricity is high |

| Kids Wear | 100% Cotton | 140 GSM Double Brush | Poly is not fire-resistant (unless treated) |

| Outdoor Jacket Lining | Polyester | 160 GSM | Must use anti-static finish |

📊 Industry Case Study

A major US bedding retailer faced a 15% return rate on their “Cozy Winter Sheets” line, which was 100% Polyester. Customers complained about “waking up sweaty” and “rough pills.”

📉 The Fix: They switched to a CVC (60 Cotton / 40 Poly) blend the following year. Returns dropped to 3%, proving that even a partial addition of cotton significantly improves moisture management.

Source: Generalized industry example.

🎨 Cotton vs Polyester Flannel: Printing & Dyeing

1. Dyeing Methods (Reactive / Vat / Disperse)

- ☁️ Cotton Flannel:Reactive dyeing is common. Deep colors require good fixation and washing-off to control crocking.

- 🔥 Polyester Flannel:Disperse dyeing is typical. You must control shade stability and consider heat exposure risks.

2. Printing Methods (Digital / Screen / Sublimation)

- ☁️ Cotton Flannel:Great for screen printing and reactive/digital methods (depending on base preparation).

- 🔥 Polyester Flannel:Best for sublimation when 100% polyester.⚠️ Note: Fuzzy surfaces can soften image sharpness—always do strike-off approvals.

3. Dark Colors vs. Light Colors

- 🌑 Cotton Darks:Watch wet rubbing (crocking) and residual loose dye.

- 🌑 Polyester Darks:Watch dye migration under heat and shade consistency across lots.

🧪 How to Test Quality: Cotton vs Polyester Flannel (AATCC/ISO/ASTM)

1. What to test for BOTH (The Baseline)

- ⚖️ GSM/weight & width consistency

- 📏 Wash shrinkage / dimensional change

- 🎨 Colorfastness to washing + rubbing (dry/wet)

- 🧶 Pilling (especially after laundering)

- 💪 Tear/tensile (woven) or bursting (knit)

- 📐 Fabric skew and seam slippage (for woven shirts)

- 👀 Shade control: lab dip / shade band / bulk approval

2. Tests where Cotton Flannel is the focus

- ☁️ Shrinkage control (warp/weft): Critical due to natural fiber relaxation.

- 🌑 Crocking on dark colors: Risk of dye rub-off on deep shades.

- ✋ Handfeel consistency after washing: Monitoring “brushing loss” (fuzz falling off).

3. Tests where Polyester Flannel is the focus

- 🧶 Pilling grade: Critical for high friction use (synthetic fibers are strong anchors for pills).

- ⚡ Static/anti-static need: Mandatory check for comfort.

- 🔥 Heat exposure sensitivity: Crucial for pressing/heat transfer workflows.

4. Sampling Plan (Protocol)

- 🎨 Lab dip vs. Strike-off: Lab dip for solid colors; Strike-off for prints/complex visuals.

- ✅ Shade band approval: Must be signed off before bulk production begins.

- 📦 Bulk Continuity: “Top of roll + Middle + End” shade check for lot consistency.

📝 What to Write in the PO / Spec Sheet (Critical Module)

Below are two copyable templates. For the same end-use, they lock in the specific key risk points for Cotton Flannel vs Polyester Flannel.

Construction: woven [plain/twill] flannel

Brushing/Nap: [one-side/two-side], nap direction requirement

GSM: target ___ + tolerance ±__%

Usable width: ___ + tolerance

Shrinkage limit: warp ≤ __% / weft ≤ __% (after specified wash method)

Colorfastness minimums: washing ≥ __ ; rubbing dry/wet ≥ / ; light ≥ __

Pilling grade: ≥ __ (if required for pants/blankets)

Shade control: lab dip + shade band; lot control policy

Inspection: 4-point system, max points per 100 yd/m = ___

Packaging: roll length, face-to-face rolling, core ID, labeling

Construction: woven/knit flannel + structure stated

Brushing/Nap: level defined (avoid “very soft” only)

GSM: target ___ ±__%

Usable width: ___

Pilling grade requirement: ≥ __ (test method specified)

Anti-static finish: required/optional + performance expectation

Shrinkage/heat stability: define dimensional change + heat exposure conditions

Colorfastness: washing + rubbing + light targets; heat migration risk noted if applicable

Shade control: lab dip/strike-off + bulk shade continuity

Inspection: 4-point system; defect list emphasizing fuzz/pilling/nap marks

Packaging: roll setting to avoid nap damage and pressure marks

⚖️ If you’re choosing between them, which spec lines MUST change?

- ☁️ Cotton Spec Focus:

Emphasize Shrinkage Limits + Rubbing Fastness (especially dark colors) + Nap Direction. - 🔥 Polyester Spec Focus:

Emphasize Pilling Grade + Anti-Static + Heat Stability/Migration. - ⚠️ Critical Warning:

For BOTH, you must lock Construction + Brushing Intensity + GSM Tolerance.

Otherwise, you will get “Same Name, Different Product.”

⚠️ Common Defects: Cotton vs Poly (And How to Avoid)

☁️ Defects More Common in Cotton Flannel

White specks in dyed fabric.

Plaid lines not straight after washing.

🔥 Defects More Common in Polyester Flannel

Fabric sticks to itself.

Permanent lines from heat setting.

🏭 Factory Experience: QC Check

We inspect flannel using the 4-Point System. Knowing the material helps your QC look for the right problems:

- Cotton Flannel: The most common deduction is “Irregular Brushing” (one side fluffy, one side flat).

- Polyester Flannel: The most common deduction is “Barre” (horizontal streaks).

💰 Cost Drivers / MOQ / Lead Time: What Changes?

1. What makes Cotton Flannel more expensive?

- Better Cotton Grade: Using longer staple fibers and higher yarn quality.

- Density & Tolerance: Higher density requirements and tighter quality tolerances.

- Dyeing Process: Deeper dye shades with stronger wash-off requirements.

- Finishing: Extra softening/enzyming + strict shrinkage control.

2. What makes Polyester Flannel more expensive?

- Yarn Choices: Microfiber, cationic, or special performance yarn choices.

- Functional Finishes: Anti-pilling + anti-static finish packages.

- Brushing: Higher loft brushing with strict pilling control.

- Printing: Special printing routes (e.g., high-quality sublimation with strike-off approvals).

3. MOQ & Lead Time Expectations

Lowest MOQ, Fastest lead time.

Moderate MOQ, Fairly quick.

Highest MOQ + Longer lead time (due to lab dips, approvals, finishing queue).

✅ Decision Checklist: Which One to Choose?

🤔 If you care most about breathability + skin comfort…

🤔 If you care most about easy care + wrinkle resistance…

🤔 If you need deep dark shades with low rubbing transfer…

🤔 If you need lowest shrink complaints…

🤔 If you need sublimation printing…

🤔 If your end-use has high friction (pants/blankets)…

🙋♀️ FAQ (People Also Ask)

1. Is polyester flannel as soft as cotton flannel?

It can be, especially microfiber polyester. However, extreme softness often comes with higher pilling risk unless an anti-pilling finish is specified.

2. Which is warmer: cotton or polyester flannel?

Polyester often feels warmer-for-weight due to lower breathability. Cotton feels warmer in a “breathable cozy” way and is usually more comfortable indoors.

3. Does cotton flannel shrink more?

Yes. Cotton flannel typically has a medium-to-high wash shrinkage risk. You must set warp/weft shrink limits and specify the test method in the PO.

4. Does polyester flannel pill more?

Often yes, particularly very fuzzy finishes (medium-high risk). A pilling grade requirement and anti-pilling finish can reduce complaints.

5. Can I sublimate on flannel?

Sublimation works best on 100% polyester flannel. Note that fuzzy surfaces may reduce sharpness, so strike-off approval is recommended.

6. What’s the best flannel for kidswear?

Usually cotton flannel for skin comfort and breathability. If using polyester, consider safety factors like anti-static and pilling controls.

7. Is “flannelette” the same as flannel?

They’re often used interchangeably, but in sourcing you should treat them as potentially different finishes/weights. Lock your specs, not just the names.

8. What should I always write in a flannel PO?

Construction + Brushing level + GSM tolerance + Shrink limits + Colorfastness minimums + Pilling grade (if relevant) + Shade control.