🧵 Introduction: The “Double-Brushed” Trap

In my 20 years of textile manufacturing, the most common misconception I encounter is that “Double-Brushed” always equals “Better.”

⚠️ The Costly Mistake

Buyers often send tech packs requesting “Double-Brushed Flannel” for a heavy winter work shirt, assuming it will just be softer.

They face a wave of returns because the fabric pilled at the elbows and the tear strength dropped so low that pockets ripped out.

🤔 Single Brushed Flannel vs Double Brushed Flannel Which should you choose?

Offers superior warmth and softness (gold standard for pajamas/sheets), but comes with a significantly higher pilling and shedding risk.

Retains more structural integrity and durability, making it the smarter choice for outerwear shirts and linings where abrasion resistance is key.

✅ Your Factory-Floor Manual

We will move to analyze pilling grades, shedding control, and shrinkage specs, giving you the exact PO templates you need to source safely.

🧶 What Is Single-Brushed Flannel?

1. The Definition

It is a woven fabric (usually cotton or blend) that has been mechanically brushed or napped on only one side—typically the weft face (the “back” side that touches the skin).

2. The Structure

The face side remains smooth, showcasing the clear weave pattern (plaid or solid), while the back side is fuzzy and soft.

3. Factory Term

Often called “Single Napped” or “Inside Brushed.”

☁️ What Is Double-Brushed Flannel?

1. The Definition

It is a fabric that has been brushed on both the face and the back side.

2. The Structure

Both sides are fuzzy, obscuring the weave pattern slightly but creating maximum “loft” (air trapping) for warmth.

3. Factory Term

Often called “Double Napped” or “Two-Side Brushed.”

4. The Trade-off: Pilling Risk

Does double brushed flannel pill more than single brushed?

Because there are more loose fiber ends on the surface exposed to friction.

⚡ Quick Answer: Single vs Double Brushed Comparison

Use this table to quickly decide single brushed flannel vs double brushed flannel difference for your product.

| Feature | Single-Brushed Flannel | Double-Brushed Flannel |

|---|---|---|

| Feel | Smooth face / Soft back | Plush, fuzzy, & soft on both sides |

| Warmth | Medium (Traps some air) | High (Traps max air/dead space) |

| Breathability | High (Clear weave) | Medium (Nap blocks airflow slightly) |

| Pilling Risk | Low-Medium (Face is stable) | High (Both sides have loose fibers) |

| Shedding Risk | Low | High (Must control lint loss) |

| Shrinkage | Moderate (3-5%) | Moderate-High (Structure is relaxed) |

| Appearance | Crisp, clear pattern | Soft, slightly “hazy” or “foggy” |

| Colorfastness Risk | Standard | High (Nap “whitening” on dark colors) |

| Typical GSM | 120 – 180 GSM (Light/Mid) | 150 – 300+ GSM (Mid/Heavy) |

| Best For | Shirts, Linings, Light Jackets | Pajamas, Flannel Sheets, Throws |

| Factory Note | “Specify ‘Brushed Back Side’ clearly.” | “Must define pilling grade requirement in PO.” |

☁️ How Brushing Changes Fabric (Why It Feels Different)

Brushing creates “loft” by physically breaking fibers on the yarn surface. This increases warmth but decreases strength.

1. Surface Fibers & Loft

The nap on the inside creates a micro-climate against the skin, while the smooth outside acts as a shield against pilling and abrasion.

The nap on both sides doubles the thickness (loft) without adding weight. It feels “spongy” and substantial.

2. Density vs. Brushing Intensity

Which matters more?

You cannot double-brush a low-density fabric (e.g., 40×40 / 100×60). The needles will tear it apart. To make good double brushed flannel, we must start with a tighter, higher-density construction.

Don’t just ask for “Heavy Brushing.” Lock the construction first.

🚫 Low-count fabric + Heavy brushing = Holes.

✨ High-count fabric + Heavy brushing = Luxury.

3. Brushing Stage in Process

Brushing happens after dyeing but before final finishing (stenter).

Brushing changes the color! It makes dark colors look lighter (“frosty”).

You must perform a handfeel reference sample review after brushing but before bulk cutting to check for flannel nap direction shading.

✋ Handfeel & Appearance: What You’ll Notice Immediately

1. Softness vs. “Smooth Back Side”

You feel the difference instantly. One side is cool/crisp; the other is warm/fuzzy.

It feels like a continuous cloud. There is no “cool side.”

2. Drape & Thickness

Shirt-friendly flannel drape recommendation is common because it falls cleaner. It doesn’t “stick” to other layers.

Feels thicker and stiffer due to the volume of the nap. It can “climb” or bunch up when worn under a jacket.

3. Nap Direction & Shading

The smooth face reflects light evenly.

Nap direction meaning in flannel fabric becomes critical.

⚖️ Performance Comparison (Warmth / Breathability / Pilling)

1. Warmth & Heat Comfort 🔥

Is double brushed flannel warmer than single brushed?

- ✅ Conclusion: Yes, significantly.

- ⚙️ Reason: The double nap creates two layers of dead air space insulation.

- 📝 PO Tip: For winter bedding, specify double brushed for maximum tog rating.

2. Breathability 🌬️

- ✅ Conclusion: Single-brushed breathes better.

- ⚙️ Reason: The unbrushed surface allows air to pass through the weave interstices more easily.

- 📝 Selection: For active shirts or summer pajamas, choose single-brushed.

3. Pilling Risk (Critical) 🧶

Does double brushed flannel pill more?

- ⚠️ Conclusion: Yes. It is the #1 complaint for flannel sheets pilling.

- ⚙️ Reason: Brushing creates millions of “free fiber ends.” Friction rolls these ends into balls.

- 📝 PO Tip: Specify anti-pilling finish and demand Grade 3.5 (ASTM D3512).

4. Shedding / Fuzzing 🌫️

- ✅ Conclusion: Double-brushed sheds more lint.

- ⚙️ Reason: More broken fibers = more lint in the dryer.

- 📝 PO Tip: Include a “Lint Loss” tolerance or require pre-wash at the factory to remove loose fly.

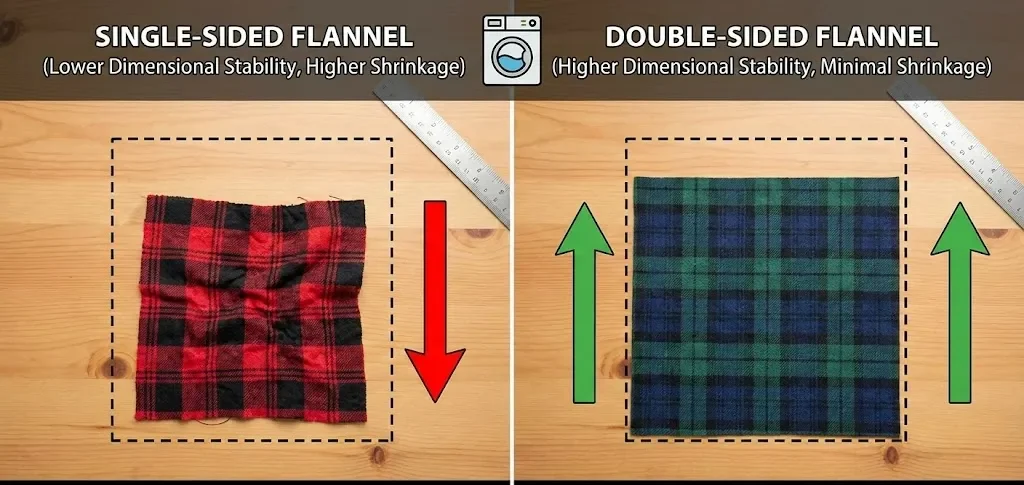

5. Shrinkage & Dimensional Stability 📏

- ☁️ Cotton Flannel: Shrinkage tolerance must be strictly controlled (Sanforized). Brushing relaxes the fabric, making it prone to shrinking.

- 🧪 Polyester Flannel: Less shrinkage, but high heat sensitivity.

- 🔗 Internal Link: See shrinkage data in our Weight Guide

6. Colorfastness (Whitening) 🎨

- ✅ Conclusion: Deep colors (Navy, Black) suffer from “Whitening” or “Frosting” on double-brushed fabric.

- ⚙️ Reason: The abrasion of brushing exposes the undyed core of the fiber or creates optical scattering.

- 📝 PO Tip: For black double-brushed flannel, set a strict rubbing fastness dry/wet test limit (Grade 3.0 wet).

🏭 Use-Case Guide for Factories (Garment vs Home Textile)

1. Garment Factory: Shirts / Overshirts / Pajamas 👕

- 👔 Shirts:

Best flannel for shirts single brushed or double brushed?

Single Brushed is better for standard shirts to prevent pilling on the outside. - 🧥 Overshirts:

Double Brushed is acceptable for heavy 300gsm “Shackets” where warmth is the priority, but use coarse yarns to reduce pilling. - 🌙 Pajamas:

Flannel for pajamas single vs double brushed?

Double Brushed is standard for comfort, but ensure the fit is loose to minimize friction pilling.

2. Home Textile Factory: Bedding / Throws 🛏️

- 🛌 Bedding:

Best flannel for flannel sheets single or double brushed?

Double Brushed is the industry standard. Customers equate “fuzziness” with quality here. - 🧶 Throws:

Always Double Brushed. - 🛡️ Prevention:

Flannel sheets lint shedding how to prevent? Use “Combed Cotton” yarns and an enzyme wash to remove weak surface fibers.

📊 End-Use Decision Table

| Product | Recommend | GSM Range | Brushing Level | Must-Test Items |

|---|---|---|---|---|

| Men’s Shirt | Single | 130-160 (Light/Mid) | Medium | Shrinkage, Seam Slippage |

| Pajama Set | Double | 140-170 (Mid) | Heavy | Pilling, Shrinkage |

| Bed Sheet | Double | 160-190 (Heavy) | Heavy | Shedding, Pilling, Skewing |

| Throw | Double | 200-300 (Heavy) | Heavy | Shedding, Colorfastness |

| Jacket Lining | Single | 120-140 (Light) | Light | Anti-Static, Rubbing |

📝 Key Specs Table (Buyer-Ready Comparison)

Copy this directly into your flannel fabric specification sheet template.

| Spec Item | Single-Brushed Spec | Double-Brushed Spec |

|---|---|---|

| Construction | Plain or Twill | Twill preferred (stronger base) |

| Brushing | Face: Smooth / Back: Brushed | Face: Brushed / Back: Brushed |

| GSM Tolerance | ± 5% | ± 5% |

| Width Tolerance | -0 / +1 inch | -0 / +1 inch |

| Shrinkage | Max 3% Warp / 3% Weft | Max 5% (unless Sanforized) |

| Pilling Grade | Min 3.5 (ISO 12945) | Min 3.0 (Harder to achieve) |

| Colorfastness | Wash 4.0 / Rub 3.5 | Wash 4.0 / Rub 3.0 (Wet) |

| Shade Control | Standard | Critical (Nap direction marking req) |

| Defect Std | 4-Point System | 4-Point System |

🧪 How to Test Quality (AATCC / ISO / ASTM)

1. Tests Both Should Pass ✅

- 📏 GSM/Width: ASTM D3776.

- 🧺 Shrinkage: AATCC 135 (3 wash cycles).

- 🎨 Rubbing: AATCC 8 (Crocking).

- 👀 Appearance: Visual check after 1 wash for nap streaks defect.

2. Tests Where Double-Brushed Needs Stricter Gates ⚠️

- 🧶 Pilling:

AATCC ISO pilling test for flannel fabric. Set the bar at Grade 3.0.Action: If it fails, reject. - 🌫️ Shedding:

Tumble dry a sample with a black cloth.Action: If the black cloth is covered in lint, fail. - 🌈 Shade Continuity:

Napped flannel color shading between rolls.Action: Check shading under D65 light.

3. Sampling Plan (Factory Workflow) 🏭

- 1️⃣ Lab Dip: Approve color on unbrushed fabric.

- 2️⃣ Golden Sample: Approve handfeel/brushing level on a 2-yard handfeel reference sample.

- 3️⃣ PPS: Wash test the Pre-production sample for shrinkage.

- 4️⃣ Bulk: Flannel fabric bulk approval process. Inspect 10% of rolls.

📜 Industry Standard: ASTM D3512

According to Standard D3512 for Pilling Resistance, napped fabrics are inherently prone to pilling.

- Double-Brushed: A rating of 3.0 (Moderate Pilling) is often the commercial acceptance limit.

- Single-Brushed: Fabrics are expected to achieve 4.0 (Slight Pilling).

📝 What to Write in the PO / Spec Sheet

📄 PO Template for Single-Brushed

- Item: Single Napped Cotton Flannel

- Brushing: Brushed Back Side Only / Face Side Smooth

- Level: Medium Nap

- Shrinkage: Max 3.0% Warp / 3.0% Weft (AATCC 135)

- Pilling: Grade 3.5 Min

- Handfeel: Match Approved Golden Sample #XYZ

📄 PO Template for Double-Brushed

- Item: Double Napped Cotton Flannel

- Brushing: Brushed Both Sides

- Level: Heavy Nap

- Pilling: Grade 3.0 Min (Strict adherence required)

- Shedding: Low Lint Loss Required (Enzyme Wash)

- Shade Control: Nap Direction Marking Required on Rolls; Shade Band Approval Required.

- Packaging: Suspended Roll Packing (to prevent crush marks).

⚠️ If Switching Single ↔ Double

- 📉 Change Pilling Gate:

Lower expectations from 4.0 to 3.0 for double. - 📐 Change Pattern:

Increase shrinkage allowance for double. - 📦 Change Packaging:

Double brushed crushes easily; do not vacuum pack tightly.

⚠️ Common Defects & Prevention Checklist

1. More Common in Single-Brushed

- 🌓 One-Side Shading:

Face side looks different from back side (normal, but must be consistent). - 〰️ Uneven Brushing:

Patches of unbrushed fabric on the back.

2. More Common in Double-Brushed

- 🧶 Pilling:

Balls forming even on the roll. - 🌫️ Heavy Fuzz Shedding:

Clouds of dust during cutting. - 📉 Nap Streaks:

Lines where the wire brush hit too hard. (Nap streaks defect on double brushed flannel). - 🔨 Pressure Marks:

Uneven brushing defect on flannel fabric caused by tight rolling.

3. ✅ Prevention Checklist

- [ ] Lock brushing level with golden sample handfeel approval.

- [ ] Perform brushed flannel wash test before bulk.

- [ ] Inspect for nap streak shading.

💰 Cost Drivers / MOQ / Lead Time

1. Why Double-Brushed Costs More 💸

“Why double brushed flannel costs more?”

- ⚙️ Process:

It requires two passes through the raising machine (one per side). - 📉 Yield Loss:

Brushing removes fiber.Example: To get a 160gsm double-brushed fabric, we might need to start with 180gsm of yarn. The “lost” 20gsm is waste.

- 🛡️ QC Risk:

Higher rejection rate for pilling or tearing defects.

2. MOQ & Lead Time ⏱️

1,000m | 15 days

3,000m | 30-40 days

5,000m | 45 days

✅ Decision Checklist (Final Summary)

(Better structure, crisp pattern).

(Traps max air/dead space).

(Set Min Grade 3.0 for Double).

(Standard for sheets & throws).

📊 Need to check weights?🔗 Internal Link: Compare Flannel Weights (GSM/OZ)

❓ FAQ: Common Questions

1. Is double-brushed flannel warmer than single-brushed?

Yes. Absolutely. The double nap creates a thicker insulation layer of trapped air (dead space).

2. Does double-brushed flannel pill more?

Yes. The increased surface area of loose fibers makes it much more prone to tangling and pilling.

3. Which is better for flannel sheets?

Double-brushed is the standard for sheets because maximum softness is the priority over structure.

4. Does brushing reduce durability?

Yes. Brushing physically breaks fibers. A heavily brushed fabric has lower tear strength than an unbrushed one.

5. How do you control nap direction and shading?

By marking the nap direction on the roll and ensuring all garment panels are cut in the same direction.

6. How to test flannel pilling quickly before bulk?

Use a “Rub Test.” Rub the fabric against itself or a wool fabric 100 times. If pills form immediately, reject the lot.

7. Can single-brushed feel as soft as double-brushed?

On the inside (skin side), yes. But it will never feel as “plush” or thick overall.