🧵 Introduction: The Hidden Cost of the Wrong Fiber

In my 20 years of textile manufacturing, I have seen brands lose millions of dollars simply because they chose the wrong synthetic fiber.

⚠️ The Cost of Confusion: Two Scenarios

I once worked with a major backpack brand that switched from Nylon to Polyester to save cost.

The Result: They faced a 30% return rate due to abrasion failure within just six months.

Conversely, I’ve seen activewear brands insist on Nylon for t-shirts.

The Result: The fabric held onto sweat odors and yellowed under store lights.

🧬 Beasts of a Different Nature

Nylon vs Polyester is the oldest rivalry in synthetic textiles. They look similar, they are both plastics, and they are often used interchangeably. But chemically and physically, they are beasts of a different nature.

✅ Your Sourcing Manual

This guide is not just a definition list. It is a sourcing manual. We will dissect the difference between nylon fabric vs polyester fabric from the fiber structure up, covering:

- Pilling risks

- Drying speeds

- UV resistance

- Cost drivers

…so you can write the perfect PO and avoid costly claims.

🧵 What Is Nylon Fabric?

1. The Definition

Nylon fabric is a synthetic thermoplastic polymer (polyamide) known for its incredible strength, elasticity, and abrasion resistance. It was the first fully synthetic fiber ever created.

2. Suitable For

Nylon jacket mens, swimwear, hosiery (stockings), high-performance activewear, nylon t shirt.

Backpacks, tents, nylon rugs, luggage, upholstery where high durability is required.

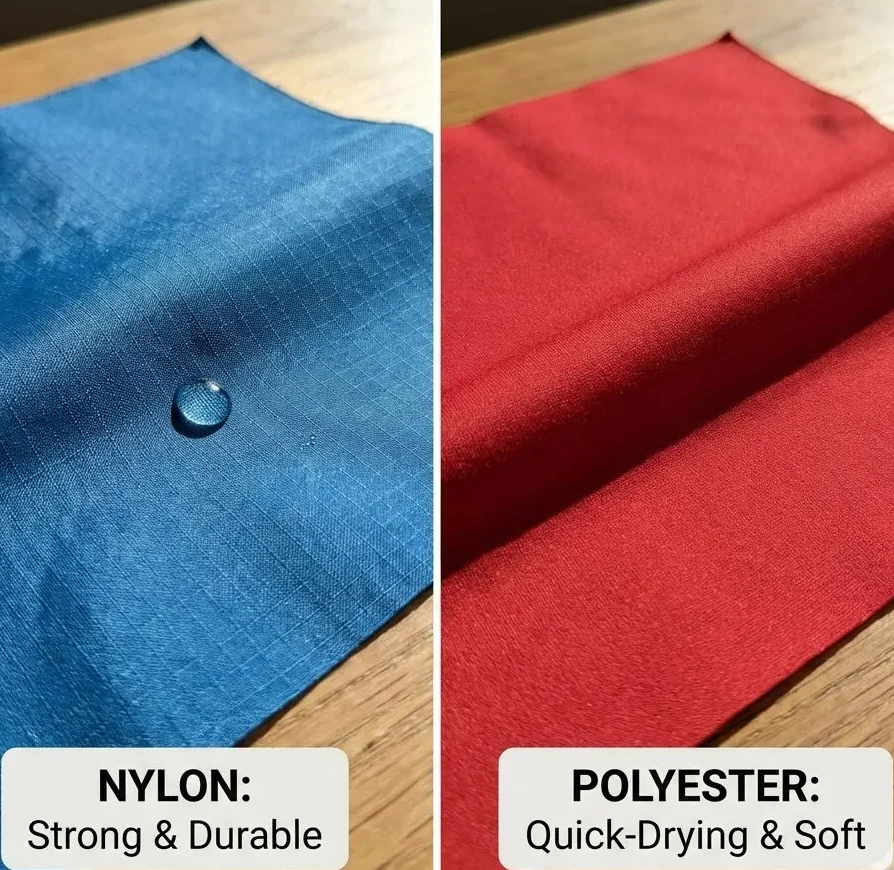

3. Key Trait 💪

It is the “Strong Man” of synthetics—hard to tear, hard to scratch.

🧵 What Is Polyester Fabric?

1. The Definition

Polyester fabric is a synthetic polymer made from purified terephthalic acid (PTA) and monotheluene glycol (MEG). It is the most widely used fiber in the world, prized for its wrinkle resistance, color retention, and affordability.

2. Suitable For

T-shirts, sportswear, fast fashion dresses, fleece jackets, uniforms.

Bed sheets, curtains, polyester carpet, outdoor cushions (due to UV stability).

3. Key Trait 🐴

It is the “Workhorse”—versatile, cheap, and easy to care for.

⚡ Quick Answer: Nylon vs Polyester Comparison Table

Use this table to quickly understand the difference between nylon and polyester performance.

| Feature | Nylon Fabric | Polyester Fabric |

|---|---|---|

| Appearance | Often glossier, smoother | Matte to semi-dull, mimics cotton/wool |

| Composition | Polyamide (Oil-based) | Polyethylene Terephthalate (Oil-based) |

| Handfeel | Smooth, silky, cool, sometimes “oily” | Dry, crisp, sometimes “plastic” or cotton-like |

| Breathability | Low (unless moisture-wicking finish) | Low (unless moisture-wicking finish) |

| Drying Speed | Fast (but absorbs 4% moisture) | Very Fast (absorbs only 0.4% moisture) |

| Wrinkle Resistance | Moderate | High (Resilient) |

| Pilling Risk | Moderate (Filament is low, Spun is high) | High (Especially Spun/Brushed) |

| Softness | High (naturally softer) | Moderate (can be engineered soft) |

| Luster | Higher natural shine | Lower natural luster |

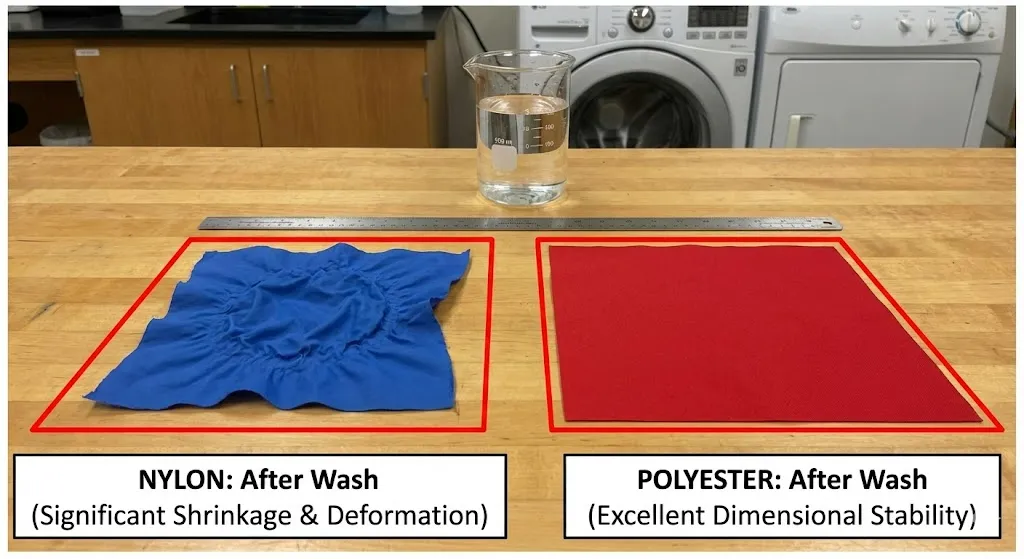

| Shrinkage | Moderate (Heat sensitive) | Low (Stable) |

| UV Resistance | Low (Yellows/degrades in sun) | High (Excellent for outdoors) |

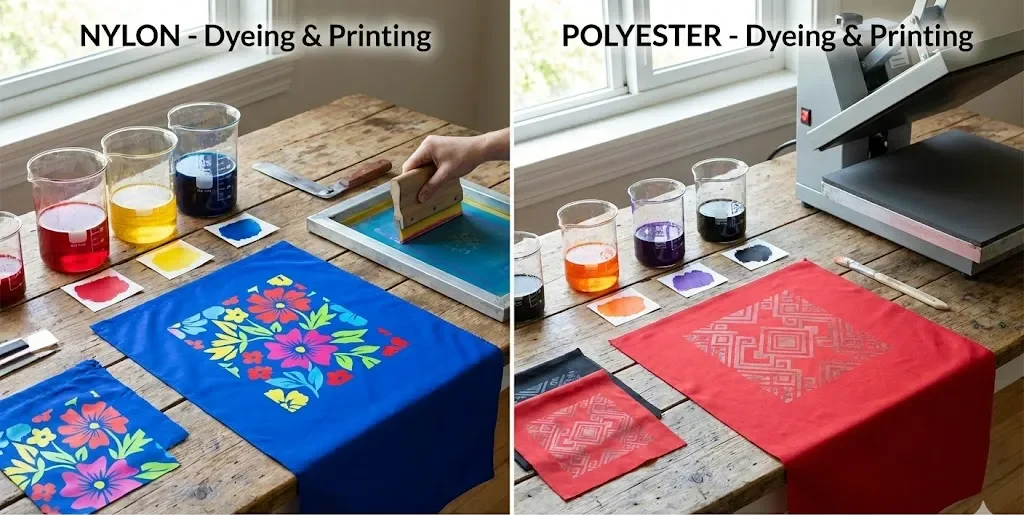

| Dyeing | Acid Dyes (Harder to control) | Disperse Dyes (Vibrant, Sublimation) |

| Cost | $$$ (More expensive) | $ (Cheaper) |

| Market Demand | High-end technical gear, swimwear | Fast fashion, basic sportswear, home |

🔍 Major Differences Detailed

1. Appearance

- Nylon Fabric: It naturally has a smoother, silkier surface. Standard nylon often has a high luster unless delustered.

- Polyester Fabric: It typically has a more matte appearance. Because it is widely used to imitate cotton (Spun Poly) or wool, it is often engineered to look less “synthetic.”

This is because nylon fibers have a rounder cross-section and a smoother surface that reflects light more directly. Polyester often uses trilobal or irregular cross-sections to mimic natural fibers, which scatters light and reduces shine.

Nylon generally looks more premium for outerwear (like down jackets or bombers) because of its fine denier and smooth drape.

Polyester can look “flat” or cheap if not processed with a high-quality finish, although high-end microfiber polyester is closing the gap.

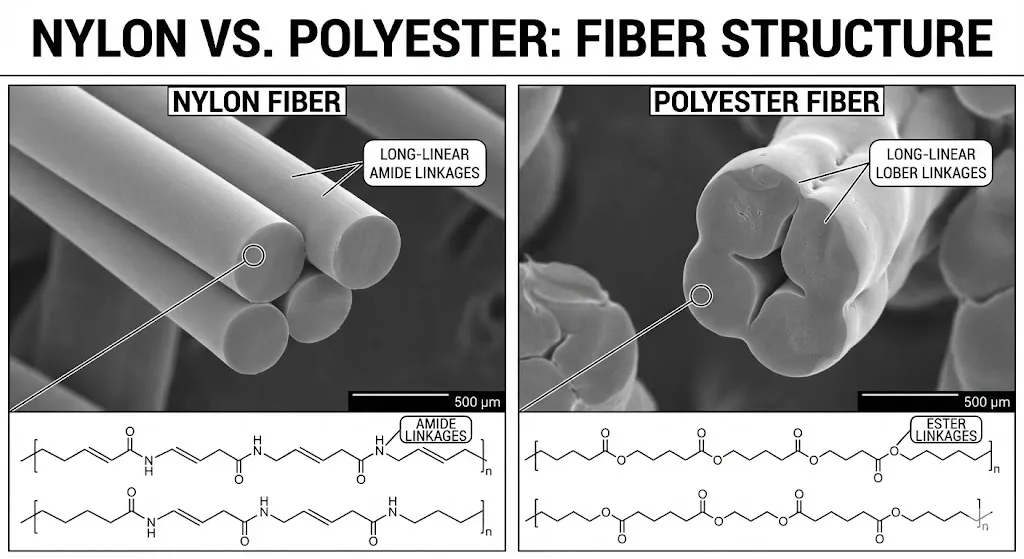

2. Composition

Nylon material is made from reacting diamine acid with dicarboxylic acid. It is a polyamide. Is nylon a polyester? No, they are chemically distinct.

According to Wikipedia on Nylon, it was the first commercially successful synthetic thermoplastic polymer, developed by Wallace Carothers at DuPont in the 1930s.

Polyester material is made from a chemical reaction involving coal, petroleum, air, and water. It is a polymer composed of ester functional groups.

Yes. Nylon absorbs about 3-4% of its weight in water, while polyester absorbs only 0.4%.

This makes nylon feel slightly more “natural” and less clammy against the skin, but it also means nylon takes longer to dry than polyester.

3. Process & Fiber Structure

- Nylon Fabric: Produced via melt spinning. The polymer chips are melted and extruded through a spinneret. The fibers are then drawn (stretched) to align the molecules, which gives nylon its exceptional elasticity and strength. Is nylon stretchy? Yes, naturally more so than polyester due to this molecular alignment.

- Polyester Fabric: Also melt spun, but the drawing process focuses on crystallization to create rigidity and wrinkle resistance.

- Nylon: Used for hosiery, parachutes, and shiny jackets. Smooth and strong.

- Polyester: Used for linings, windbreakers, and sportswear base layers.

- Nylon: Rare. Mostly used in blends (e.g., Nylon/Wool) to add strength.

- Polyester: Extremely common. Used to make polyester fabric t shirt that feels like cotton. High pilling risk.

- FDY (Fully Drawn Yarn): Smooth, flat, and shiny. Used for linings.

- DTY (Drawn Textured Yarn): Crimped, fluffy, and soft. This makes polyester feel like cotton.

Often, yes. A loose knit nylon clothes item will pill faster than a tight woven polyester item. You must balance fiber properties with construction.

4. Handfeel

- Nylon Fabric: What does nylon feel like? It feels cool, slick, and sometimes slightly “oily” or waxy (in a good way). It is softer to the touch than polyester of the same weight.

- Polyester Fabric: What does polyester feel like? It feels drier, crisper, and can feel “plastic-y” if low quality. Textured polyester (DTY) mimics the fuzziness of cotton.

This is because of Texturing. One fabric uses FDY (flat, slippery lining) and the other uses DTY (soft, fluffy fleece). They are chemically identical but physically opposite.

Nylon generally feels less plastic and more like silk. Polyester has fought hard to shed its “plastic” reputation through microfiber technology, but standard polyester still has that characteristic dry friction sound.

5. Breathability

Is nylon breathable? Technically, neither fiber is breathable (air permeable) on its own because they are solid plastics. However, nylon absorbs more moisture (hydrophilic tendencies), so it can feel less suffocating than polyester, which is hydrophobic and traps sweat vapor against the skin.

It is the lack of moisture absorption. Sweat stays on the skin instead of being absorbed by the fabric. Is polyester breathable? Only if the weave is open or if wicking finishes are applied.

- Structure: Use a mesh or open knit construction.

- Finish: Apply a Hydrophilic Wicking Finish (e.g., 3M Scotchgard) that spreads sweat across the surface for rapid evaporation.

6. Drying Speed

- Nylon Fabric: Dries fast, but slower than polyester because it holds onto water molecules inside the fiber structure.

- Polyester Fabric: Dries very fast. Water sits on the surface and evaporates instantly.

Because “Quick Dry” means water leaves the fabric, not necessarily that it leaves your skin. If the fabric relies solely on hydrophobicity, sweat beads up between your skin and the shirt, creating a “greenhouse effect.”

Actually, polyester is notorious for holding body odors (oleophilic – absorbs oils). Nylon is somewhat better, but all synthetics struggle with odor compared to Merino wool or cotton.

Body oils bind to the hydrophobic surface of polyester and attract bacteria.

7. Wrinkle Resistance

Polyester wins. It is inherently resilient. You can wash a polyester shirt and wear it without ironing. Nylon is good, but it can crease if left in a hot dryer or crushed in a suitcase.

Nylon has a lower melting point than polyester. If you iron it too hot, you melt the surface fibers, creating permanent “shine marks” or fusing the creases.

For nylon, we often add a mild resin finish or use high-twist yarns to improve recovery. For polyester, heat setting during the stenter frame process locks the fabric flat permanently.

8. Pilling

Generally, Nylon pills less than polyester because nylon fibers are incredibly strong and flexible. However, Spun Nylon (used in wool blends) pills badly. Is nylon a good fabric? Yes, its resistance to pilling makes it ideal for high-friction areas like backpack backs or inner thighs of leggings.

Polyester fibers are strong but brittle. When loose fiber ends (from DTY yarn or brushing) tangle into balls, they are too strong to break off. They stay attached, forming ugly pills. Which pills more? Polyester, especially in soft knits.

- Use High Twist Yarns: Tightly twisted yarn holds fibers in place.

- Singeing (Gas): Burn off surface fuzz.

- Enzyme Wash (Bio-Polish): Eat away loose fibers (mostly for cellulosic blends, but chemical etching exists for synthetics).

- Heat Setting: Stabilize the fabric surface.

9. Softness

- Nylon Microfiber: Feels like “buttery” skin. Think of high-end yoga leggings (Lululemon Align uses Nylon blends).

- Polyester Microfiber: Feels like “peach skin” or suede. Soft, but drier.

- Winner: Nylon is naturally softer.

It mechanically breaks surface fibers to create fuzz. This increases softness drastically but also skyrockets the pilling risk.

10. Luster

As mentioned, the round cross-section reflects light. Nylon jacket mens styles often exploit this for a technical, sporty look.

- Yarn Selection: Specify “Full Dull” (FD), “Semi-Dull” (SD), or “Bright” (BR) yarn in the PO.

- Chemical Delustering: Titanium Dioxide is added to the melt to reduce shine.

Use Full Dull (FD) yarn. Or, use a Taslan process (air-jet texturing) which gives nylon a matte, cotton-like appearance.

11. Shrinkage & Dimensional Stability

Yes. Nylon is more sensitive to heat and moisture relaxation. Without heat setting, nylon can shrink 5-10%. Polyester is very stable and rarely shrinks more than 1-2%.

Nylon. Ironing nylon requires a low setting. Polyester can withstand higher heat (e.g., for sublimation printing).

- Nylon: “Max 3% Warp / 3% Weft (AATCC 135, Low Heat Dry).”

- Polyester: “Max 1% Warp / 1% Weft (AATCC 135, Tumble Dry).”

12. UV Resistance / Yellowing

Polyester is the clear winner. The polymer structure reflects UV rays. Nylon degrades and weakens under prolonged sun exposure.

Yes, nylon clothes yellow and become brittle (UV degradation).

You must add UV Stabilizers during the dyeing process. Even then, for outdoor gear (tents/flags), Polyester is superior.

AATCC 16.3 (Colorfastness to Light). For outdoor gear, specify Class 4.0 after 40 hours.

13. Dyeing & Printing

Nylon uses Acid Dyes, which are tricky to control (streaks are common) but produce rich colors. Polyester uses Disperse Dyes, which require high pressure/temp but are very stable.

Is polyester better for sublimation? Yes. Sublimation requires 200°C heat to turn ink into gas. Polyester can handle this heat and the dye bonds chemically. Nylon would melt or turn yellow at this temperature.

- Nylon Fabric: Colorfastness to washing is the risk. Acid dyes can bleed in warm water.

- Polyester Fabric: Colorfastness to rubbing (crocking) is the risk. Excess dye sits on the surface.

- Nylon: Jig Dyeing (for woven) or Winch/Jet (for knits). Risk: Shade variation.

- Polyester: Jet Dyeing (High Temp/High Pressure). Risk: Crease marks.

14. Cost

Yes. Nylon is typically 30-50% more expensive than polyester.

The raw materials (caprolactam) are costlier, and the manufacturing process (melt spinning) is more energy-intensive.

Denier (finer is more expensive), Weave density (Taffeta vs Oxford), and Coatings (PU/PVC).

Yarn type (Microfiber/DTY costs more than FDY), Weight (GSM), and Functional Finishes (Wicking/Anti-bacterial).

- Nylon Fabric: MOQ is often higher (3000m+) because there are fewer stock colors. Lead Time is longer (30-45 days).

- Polyester Fabric: Huge stock market. MOQ can be 1 roll (100m) for stock colors. Lead Time is fast (15-20 days).

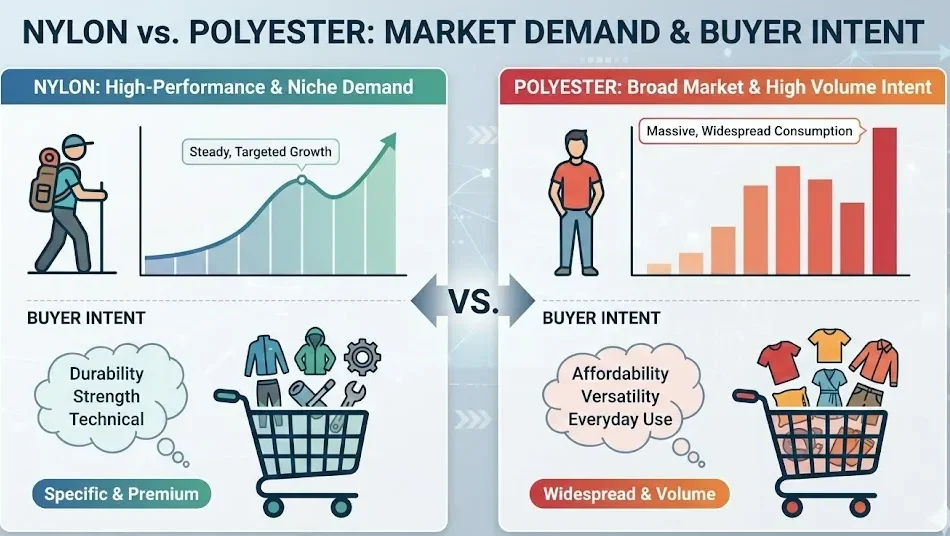

15. Market Demand / Buyer Intent

Because of the “Perceived Value.” Nylon feels softer, quieter, and stronger per weight. A nylon jacket mens bomber sells for $200; a polyester one sells for $80.

Cost and Sublimation. You can print crazy patterns cheaply, and the fabric is durable enough for mass market.

Polyester volume is winning, but Recycled Nylon (Econyl) is trending for sustainable luxury.

Polyester. Every mill makes it. Nylon requires specialized mills.

🧪 Nylon or Polyester Test Quality (AATCC/ISO/ASTM)

1. Tests for Both (Standard)

- 📏 GSM: ASTM D3776.

- 🧺 Shrinkage: AATCC 135.

- 💪 Tensile Strength: ASTM D5034.

- 📉 Tear Strength: ASTM D1424.

2. Tests Where Nylon Needs Attention ⚠️

- 🛡️ Abrasion:

ASTM D4966 (Martindale).Criteria: Nylon should exceed 20,000 cycles. - 🧶 Snagging:

ASTM D3939 (Mace Snag).Critical for filament nylon. - ☀️ Yellowing:

Phenolic Yellowing Test (Courtaulds).

3. Tests Where Polyester Needs Attention 🐴

- ☁️ Pilling:

ASTM D3512 (Random Tumble). - 💧 Wicking:

AATCC 79 (if activewear). - ⚡ Static:

AATCC 115.

4. Sampling Plan

- 1️⃣ Lab Dip: Approve color.

- 2️⃣ PPS: Approve handfeel and shrinkage.

- 3️⃣ Bulk: Shade band approval required before shipping.

📜 Industry Standard: ASTM D4966

According to Standard D4966 for Abrasion Resistance, Nylon fabrics consistently outperform Polyester fabrics of equivalent weight, often withstanding 2-3 times more cycles before failure.

⚠️ Common Defects & How to Avoid (Factory Troubleshooting)

1. More Common in Nylon

- 🧶 Snagging: Filament yarns pull out easily.🛠️ Fix: Tighter weave.

- 🔥 Shine Marks: Over-pressing at the factory.🛠️ Fix: Lower ironing temp.

- 🌈 Dye Unevenness (Barre): Yarn variation shows as stripes.

- 🛠️ Fix: Don’t mix yarn lots + run a barre test before bulk.

2. More Common in Polyester

- ☁️ Pilling: The number one defect.

- ⚡ Static: Fabric sticking together in cutting.

- 🎨 Heat Migration: Dye moving during storage.

3. ✅ Prevention Checklist

- [ ] Specify “Full Dull” yarn to avoid cheap shine.

- [ ] Require “Anti-Static Finish” for Polyester.

- [ ] Require “Grade 4.0 Pilling” in PO.

✅ Decision Checklist

(e.g., Backpacks, Luggage)

(e.g., Uniforms, Promo Items)

(e.g., Graphic Tees)

(e.g., Yoga)

(e.g., Flags, Cushions)

(UV resistant)

❓ FAQ (People Also Ask)

1. Is nylon stronger than polyester?

Yes. In terms of strength-to-weight ratio, it is superior. A 50D Nylon is stronger than a 50D Polyester.

2. Which is better for activewear?

It depends. For yoga/compression, Nylon is better (softer, stretchier). For running/sweating, Polyester is better (dries faster, wicks better).

3. Which dries faster?

Polyester. It holds almost no water.

4. Which pills more?

Polyester generally pills more, especially in spun or brushed forms.

5. Is nylon more breathable?

Slightly more than polyester because it absorbs some moisture, preventing that “plastic wrap” feeling.

6. Is polyester better for sublimation?

Yes. You cannot sublimate Nylon effectively.

7. Nylon 6 vs 6,6—does it matter?

Yes. Nylon 6,6 is stronger, has a higher melting point, and feels softer. It is the premium choice.

8. Which is better for backpacks?

Nylon. It resists tearing and abrasion much better. Nylon rugs vs polyester rugs follows the same logic: Nylon lasts longer.

9. Which is more UV resistant?

Polyester. Nylon rots in the sun.

10. Which is cheaper?

Polyester is significantly cheaper.

11. Which is more eco-friendly?

Both are plastics. However, Recycled Polyester (rPET) from bottles is widely available and scalable. Recycled Nylon (from fishing nets) is scarcer and more expensive.

12. Which is better for swimwear?

Nylon. It stretches better and feels softer against the skin, but it needs chlorine-resistant spandex to last.