🧥 Introduction: Denim Jacket Fabric Specifications

Before we jump into numbers, here is the critical distinction you must understand.

⚠️ A Denim Jacket Is Not Specified Like Jeans

Jackets use larger panels (back yoke, sleeves, collar stand), they show shade variation more easily, and they suffer from different stress points (elbows, armholes, pocket corners, hem).

If you copy a jeans spec and call it a jacket spec, you usually pay for it later—in crocking complaints, panel mismatch, seam puckering, or shrinkage that destroys symmetry.

🧵 Defining “Denim”

“Denim” itself has a precise meaning: it’s a warp-faced twill textile where the weft goes under two or more warp threads, creating the diagonal rib that visually defines denim.

📘 In This Guide, I Will Give You:

- Copy-paste spec “defaults” for three jacket styles.

- The step-by-step logic to adjust each parameter confidently.

- A denim jacket fabric spec sheet template you can hand to suppliers.

📏 Denim Jacket Fabric Specifications — Quick Answer

1. Best Default Spec for a Classic Trucker Jacket (Core Numbers)

If you want one “safe commercial” starting point that works for most classic trucker jackets, use this baseline and then tune by season and wash.

Trucker Jacket Default - Fiber: 100% cotton (or up to 1–2% elastane only if you want comfort-stretch).

- Weave: 3/1 twill (classic).

- Weight: 10–13 oz/yd² (≈ 340–440 GSM) — Keyword note: this is your “best denim weight for jackets” range for mainstream retail.

- Yarn count (typical): warp 7S–12S, weft 10S–16S (ring-spun preferred for vintage character).

- Width: 57/58″ (≈ 145–150 cm) or 59/60″ (≈ 150–152 cm) cuttable width confirmed.

- Shrinkage target: warp ≤ 3%, weft ≤ 3% (after agreed wash method).

- Rubbing fastness (crocking): Set targets using a recognized rubbing test method.

- Pick your jacket season (SS vs FW) → choose the weight inside 10–13 oz.

- Pick your wash look (raw / rinse / vintage) → decide how strict your crocking and shade band control must be.

- Decide “structure vs comfort” → choose 3/1 twill 100% cotton (structure) or add minimal stretch (comfort).

- Lock the numbers in a one-page spec and require lab dips + bulk cuttable approvals.

Note: Most disputes happen because buyers skip steps 2–4 and “approve by feeling,” then discover the fabric behaves differently after washing.

2. Best Default Spec for a Workwear Denim Jacket (Durability-First)

Workwear jackets are punished harder: abrasion from tool belts, repeated laundering, heavier trims, and seam stress. Your fabric should be tough before it’s pretty.

Workwear Default - Fiber: 100% cotton or cotton/poly blend (for dimensional stability/drying).

- Weave: 3/1 twill or broken twill (for torque control).

- Weight: 12–16 oz/yd² (≈ 410–540 GSM).

- Yarn count: warp 6S–10S, weft 8S–12S (coarser yarn = more toughness).

- Width: 150–160 cm preferred for marker efficiency.

- Performance emphasis: Specify targets for tear strength and abrasion resistance.

- Finish: Avoid aggressive softeners that reduce strength; keep finishing controlled.

Buyers often pick heavy denim and request an aggressive vintage wash. Heavy wash + heavy denim can kill strength faster than you expect. Workwear specs should explicitly describe wash assumptions and acceptance criteria.

3. Best Default Spec for a Fashion/Soft Denim Jacket (Comfort-First)

Fashion jackets often need softer drape, less “armor,” and better immediate comfort—especially for oversized, cropped, or women’s silhouettes.

Soft Denim Jacket - Fiber: Cotton + lyocell/Tencel (softness) or cotton + minimal stretch.

- Weave: 2/1 twill (often drapes softer than 3/1).

- Weight: 8–11 oz/yd² (≈ 270–380 GSM).

- Yarn count: warp 10S–16S, weft 12S–20S.

- Finish: Enzyme + controlled softening; avoid over-softening if you need shape retention.

- Risk emphasis: Panel shade mismatch shows more on fashion silhouettes → tighter lot control is needed.

Buyers often chase softness with heavy chemical softeners, then complain about seam puckering, panel mismatch, or weak crocking. Softness must be engineered, not guessed.

🧥 Start with the Jacket Type

Style and lining change the spec. You must define the jacket type first to determine the correct fabric parameters.

1. Classic Trucker Jacket: Structure, Fade, Balanced Comfort

A trucker jacket is basically the “denim jacket reference model.” It needs enough body to hold collar and yoke shape, but not so much weight that it becomes stiff and uncomfortable.

📋 What I specify first (in order):

- Weight: 10–13 oz baseline.

- Weave: 3/1 for classic.

- Dye method: Indigo for classic fade.

- Shrink and skew limits.

- Crocking targets: Because indigo rub-off is common.

If your brand story includes “heritage fade,” you’ll likely choose rope dyed indigo. Rope dyeing is associated with strong fade character, but you should expect higher rub-off risk and design your colorfastness requirements accordingly.

2. Workwear Jacket: Abrasion, Tear Strength, Durability

Workwear jackets aren’t judged by “nice fade.” They’re judged by “still alive after abuse”.

🛠️ What changes vs trucker:

- You usually push weight up (12–16 oz) and yarn coarser.

- You must define tear and abrasion performance clearly (method + target).

- Seam areas matter more: pockets, underarm seams, elbow zones.

3. Sherpa/Lined Denim Jacket: Bulk & Shrink Management

Lined jackets are where many fabric specs fail—because the outer denim and inner lining shrink and relax differently. If you don’t plan for that, you get twisting, puckering, and a jacket that hangs crooked.

🧶 Key Spec Shifts:

- Choose denim that is sanforized or otherwise shrink-controlled.

- Tighten lined denim jacket fabric shrinkage limits and require wash testing as a system (outer + lining), not only outer fabric.

- Confirm the denim can sew cleanly without needle lines, especially when thickness stacks at collar stand, cuffs, and hem.

4. Cropped/Oversized Fashion Jacket: Drape vs. Stiffness

Oversized silhouettes highlight drape and movement. Cropped silhouettes highlight shape and symmetry.

✨ Key Tradeoffs:

- Oversized: Often benefits from 2/1 twill or blends that soften drape.

- Cropped: Styles need better dimensional stability so the hem and body stay balanced.

- Shade Control: For fashion jackets, you must manage shade uniformity more strictly because wide surfaces show differences immediately.

⚖️ Recommended Denim Weight (oz/GSM) for Jackets

1. Lightweight Spring/Summer Jackets 🌤️

For warm weather, your denim should feel breathable and flexible, not sweaty and rigid.

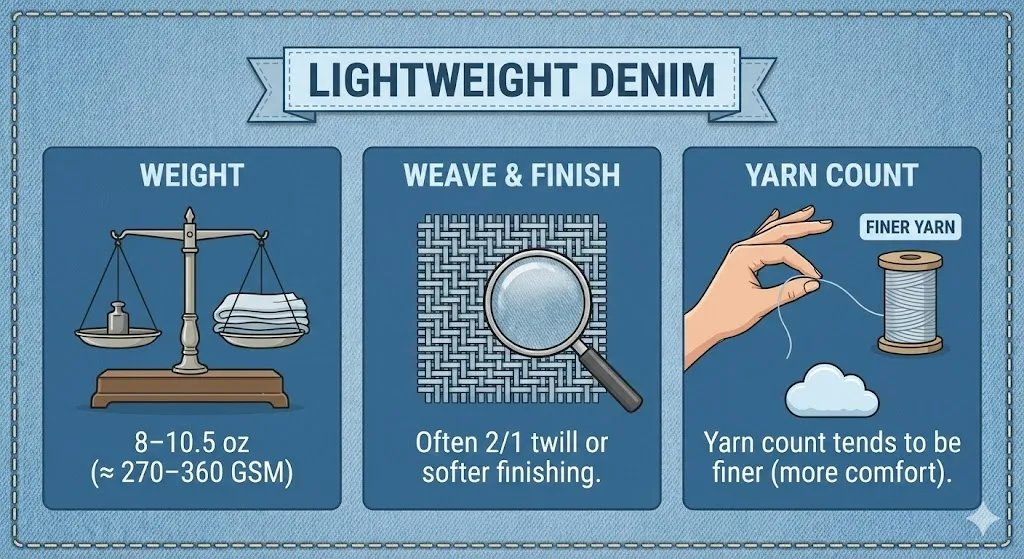

📉 Typical SS Range:

- 8–10.5 oz (≈ 270–360 GSM)

- Often 2/1 twill or softer finishing.

- Yarn count tends to be finer (more comfort).

Take a proto jacket pattern and drape the fabric on a hanger with the pattern panels clipped. If the fabric collapses too much, your collar will lose shape. If it stands too stiff, you’ll get a boxy look. This is the fastest pre-sampling filter before spending money on lab dips.

2. Midweight All-Season Jackets (Safest Commercial Range) 🧥

For mainstream retail, this is the sweet spot. Buyers often ask for denim jacket fabric weight oz gsm details here to compare factory offerings apples-to-apples.

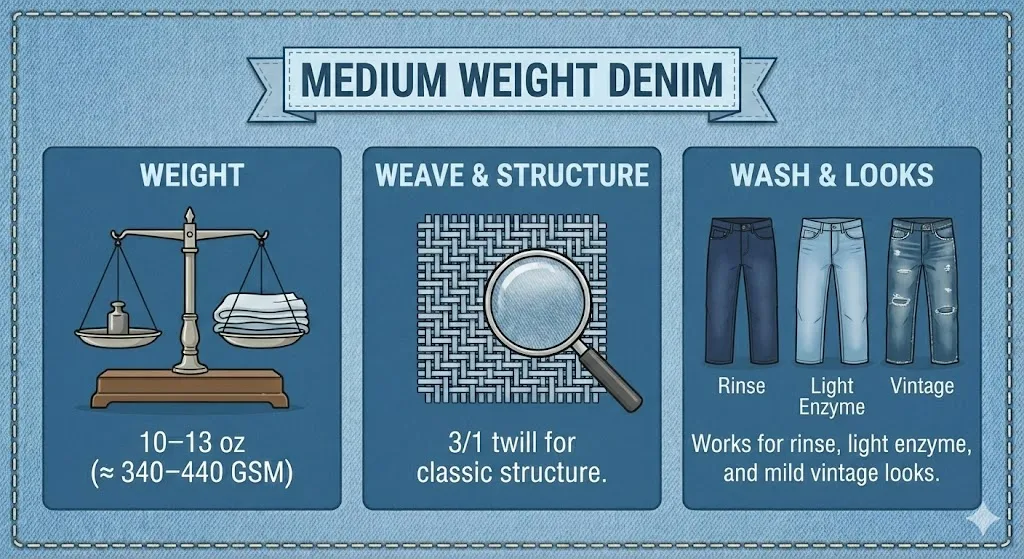

🎯 Typical Range:

- 10–13 oz (≈ 340–440 GSM)

- 3/1 twill for classic structure.

- Works for rinse, light enzyme, and mild vintage looks.

3. Heavyweight Workwear/Heritage Jackets ⚒️

Heavyweight makes sense if you want visible texture, strong structure, premium “break-in” storytelling, or true durability.

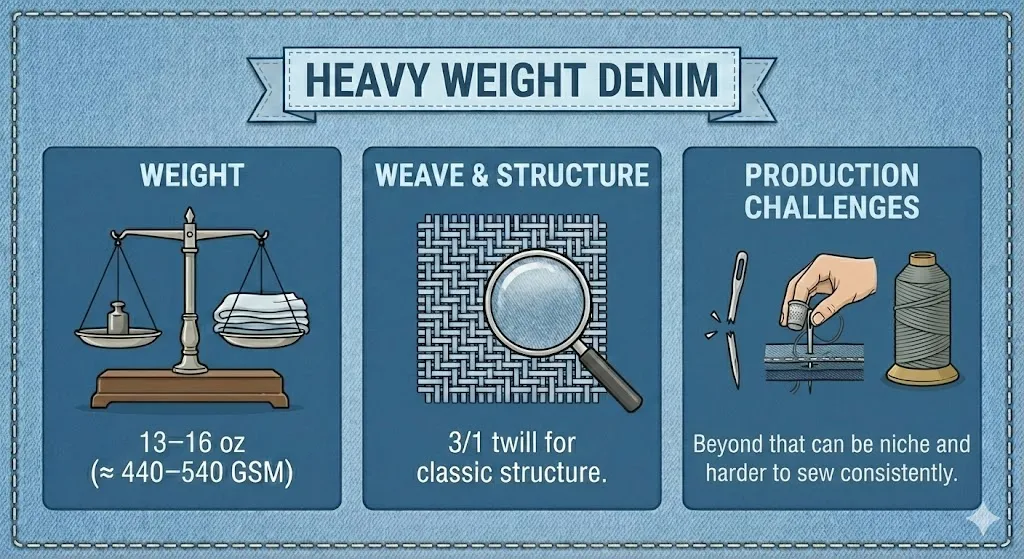

🛡️ Typical Range:

- 13–16 oz (≈ 440–540 GSM)

- Beyond that can be niche and harder to sew consistently.

Heavy weight + Aggressive wash = Strength loss + Seam issues. Decide which matters more: the wash look or the lifespan.

4. Why Jacket Weights Differ from Jeans (The Common Mistake)

People copy jeans specs because jeans are the most common reference. But the mistake is not “using jeans weight”—it is using jeans assumptions without jacket-specific controls.

🔍 Key Differences:

- Panel Size: Jacket back panels are larger and show shade variation more than jeans legs.

- Stress Points: Jeans stress the seat/knees; jackets stress elbows, underarms, and front placket edges.

- Construction Stacking: Jackets stack thickness at collar/cuffs/plackets, causing needle line risk.

🧵 Weave & Construction Specs (The “Jacket Hand-Feel” Engine)

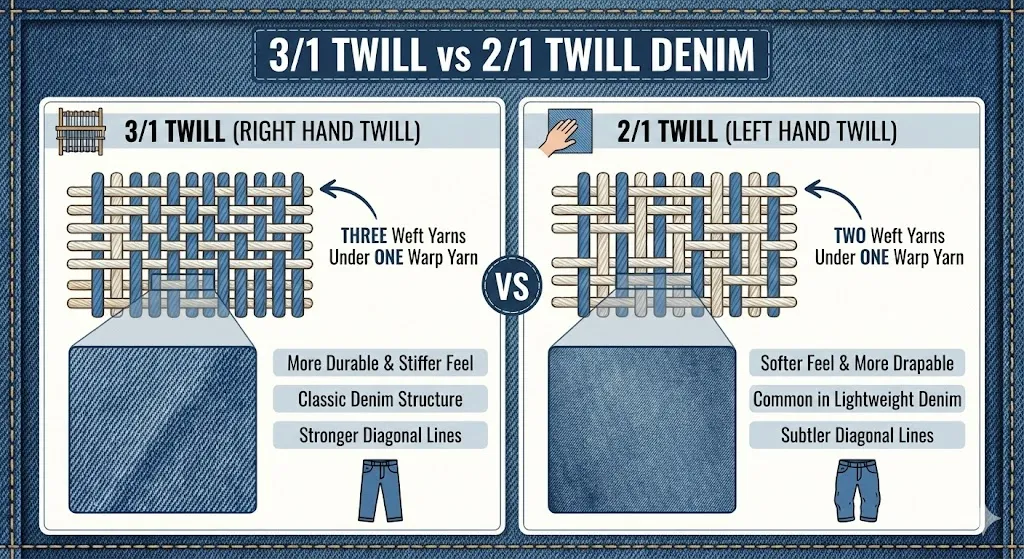

1. 3/1 Twill vs 2/1 Twill: Stiffness, Drape, Cost

This is your headline decision for “feel.”

- 3/1 Twill: Classic denim look and structure; often more rugged appearance.

- 2/1 Twill: Can feel softer and drape more; often used for lighter jackets and fashion.

- If your jacket has sharp yokes, flap pockets, and a structured collar → start with 3/1.

- If your jacket is oversized, cropped, or meant to layer lightly → consider 2/1.

2. Right-Hand vs Left-Hand Twill: Abrasion & Softness

Right-hand twill is common and tends to feel sturdy. Left-hand twill can feel smoother and may show wear differently. Don’t over-romanticize this choice; treat it as a style preference unless your customer has a very specific look target.

Ask the factory for both twill directions in similar weight, then wash both with your intended method. Choose the one that hits your look and comfort target after wash—not just in greige.

3. Broken Twill for Jackets: What It Actually Helps

Broken twill is famous in jeans for reducing leg twist. Jackets don’t have “leg twist,” but broken twill can still help:

- Reduce panel torque and skew tendency.

- Improve appearance stability after repeated washing.

- Reduce the visibility of the diagonal rib pattern (cleaner surface).

If your customer complains “the jacket hangs crooked after wash,” broken twill is a candidate solution—but you still must control shrink and skew properly.

4. Slub / Crosshatch: When Texture Sells vs. Backfires

Texture can be premium (vintage, artisanal), but it can also look like defects to conservative buyers.

Heritage storytelling, fashion silhouettes wanting visual richness, customers who love “character.”

Uniform programs, high consistency brand standards, low tolerance for barre or streaking.

If you specify slub, define it with measurable language (yarn type, variability tolerance) instead of “nice slub.” And plan stricter panel matching.

🧬 Fiber Composition & Stretch (What to Specify—and What to Avoid)

1. 100% Cotton: Best for Structure & Fade 🌿

For classic jackets, 100% cotton is still the easiest route to:

- Consistent shape maintenance.

- Authentic heritage look.

- Predictable, authentic aging.

Cotton is not “hard to fade.” Indigo fades because it sits on fiber surfaces; your fade story is more about dye method and finishing than “cotton vs not.”

2. Low-Stretch “Comfort” Denim: Acceptable % for Jackets 🧘

Stretch in jackets is usually minimal because excessive stretch causes growth at elbows and the jacket loses shape.

📉 Guidance:

- Elastane around 1–2% for subtle comfort.

- Prioritize recovery (snap-back) more than stretch amount.

- If you do stretch jackets, you must specify how to test stretch and recovery and define acceptable growth after repeated wear or wash.

3. Poly Blends: When You Want Stability or Cost Control 🏗️

Cotton/poly blends can reduce shrink and help dimensional stability. They can also help faster drying. But they may reduce “heritage fade character” and change hand feel.

✅ Use Blends When:

- It’s a uniform or workwear program.

- You need stable repeatability across lots.

- You want better shrink control.

4. Lyocell/Tencel Blends: Softness Upgrade & Tradeoffs ✨

Lyocell blends can feel noticeably softer and drape better—great for fashion jackets. But they introduce risks.

⚠️ The Tradeoffs:

- Different shrink/relaxation behavior.

- Higher risk of seam puckering if finishing isn’t tuned.

- Potential strength tradeoffs depending on blend and construction.

Pro Tip: Treat blends as “comfort engineering” and test them like a system (wash + sewing + wear simulation).

5. Stretch & Recovery Targets (So Elbows Don’t Bag Out) 📉

“Bagging at elbows” is one of the fastest ways a jacket looks cheap. If you add stretch, you need recovery rules.

🛠️ Step-by-Step Specification:

- Decide the jacket’s intended fit (regular vs slim).

- Decide if you truly need stretch. Many jackets don’t.

- If yes, specify:

- Stretch direction (weft, sometimes bi-stretch)

- Recovery requirement after a defined extension

- Acceptable growth after repeated cycles

If you don’t define recovery, you will receive fabric that “stretches nicely” but never returns.

🧵 Yarn Specs (Count, Spinning Method, and Why Buyers Argue)

1. Yarn Count Ranges for Jacket Denim (By Weight Tier)

Yarn count is where buyers and mills misunderstand each other because “12 oz denim” can be made with different yarn strategies.

- Light (8–10.5 oz): Warp 10S–16S, Weft 12S–20S

- Mid (10–13 oz): Warp 7S–12S, Weft 10S–16S

- Heavy (13–16 oz): Warp 6S–10S, Weft 8S–12S

2. Ring-Spun vs. Open-End: Real Effect on Hand-Feel & Look

Often gives a more premium, “hairy,” vintage character.

Can be more uniform and cost-efficient, but may feel less premium depending on the program.

If your brand story sells “heritage,” ring-spun is often worth it. If your program is uniform/workwear with strict consistency, OE may be acceptable if performance holds.

3. Slub/Uneven Yarn: How to Specify “Texture” Without Defects

Never write “nice slub.” That’s a dispute waiting to happen.

- Specify slub intent (subtle / medium / heavy).

- Require an approved standard swatch as reference.

- Define acceptance for barre, streaks, and panel matching.

- Require fabric inspection rules (and whether panel matching is required in cutting).

4. Compact/Combed Options: When Premium Jackets Need It ✨

Compact spinning and combed cotton can reduce hairiness and improve uniformity.

🏆 Use When:

- You want a cleaner surface.

- You need better consistency for fashion silhouettes.

- You want fewer random streaks.

“Premium doesn’t always mean ‘more texture.’ Sometimes premium means ‘cleaner and more controlled.'”

📐 Width, Usable Width, and Marker Efficiency

1. Standard Width for Denim Jackets (Why Cuttable Width Matters)

Suppliers love quoting “fabric width,” but cutters care about usable/cuttable width. Selvedge, edge defects, and skew can reduce usable width.

🛠️ Step-by-Step (What I Do):

- Ask for nominal width AND usable width.

- Require a bulk roll check: measure width every X meters.

- Require edge defect mapping if the factory has frequent selvedge issues.

- Calculate marker efficiency using usable width, not nominal width.

This saves money and avoids surprises in cutting.

2. Shrinkage Allowance: How It Changes Marker Planning

Shrink changes everything. Shrinkage is not a “lab note”—it is a production planning parameter.

- If fabric shrinks more than expected, your garment measurements drift.

- If shrink differs across lots, you get size inconsistency.

Your denim jacket shrinkage tolerance should be defined after the agreed wash method. For dimensional change testing after home laundering, AATCC TM135 is widely used for determining length/width changes under home laundering procedures.

3. When Narrow-Width / Selvedge Makes Sense

Selvedge jackets can be a premium story, but narrow width reduces efficiency and can increase cost.

✨ Choose it when:

- Your brand story demands it.

- You’re okay with higher cost.

- You plan cutting carefully to avoid panel mismatch.

“If the program is commercial retail, wide width is usually the smarter default.”

🎨 Dyeing Method & Shade Control (Prevent “Same Jacket, Different Blue”)

1. Rope-Dyed Indigo: Best for Fading, Higher Risk for Rub-Off

Rope dyeing is popular for fade potential, but indigo rubbing off is a real risk. That’s why you must specify denim jacket crocking test requirements and control finishing.

- ISO 105-X12: Specifies a method for determining colour fastness to rubbing (dry and wet). (Source: ISO)

- AATCC TM8: Specifically designed to determine the amount of color transferred by rubbing. (Source: members.aatcc.org)

2. Sulfur Black/Colored Denim: Shade Risks & Locking Them

Sulfur dye can be great for black denim jackets, but you must control:

- Undertone (green vs. red).

- Shading drift across lots.

- Wash effect changes.

- Define acceptable shade band range using approved standards.

- Prohibit mixing shade bands in one garment.

3. Overdye / Garment Dye: Style Wins vs. Consistency Risks

Garment dye can create amazing fashion colors, but it increases lot variation risk, trim staining risk, and unpredictable shrink/torque changes.

🛡️ The Requirement:

You must require garment dye trials before bulk approval and define acceptable appearance tolerance.

4. Shade Bands, Lot Control, Approvals (Lab Dip vs Bulk)

- Approve Lab Dip: Color/shade standard for indigo depth.

- Approve Bulk Cuttable: Fabric from bulk lot including hand feel.

- Approve PP Sample: With wash method identical to bulk.

- Approve TOP: From bulk production, final wash.

If you skip Step 2 and approve only the lab dip, you’re approving color in theory, not in reality.

✨ Finishing Options That Matter for Denim Jackets

1. Sanforized vs Unsanforized: What to Specify for RTW

Sanforized (Safer): Reduces residual shrinkage and improves dimensional stability. For most commercial RTW jackets, sanforized is the standard.

- Accept higher shrink and shape change.

- Define how the consumer should wash.

- Build measurement allowances into your pattern.

2. Softening & Enzyme Finishes: Comfort Without Killing Strength

Softening is where you can accidentally weaken the fabric. Enzyme and softeners improve comfort, but risky if uncontrolled:

- Too strong: Strength loss.

- Too uneven: Panel mismatch.

- Wrong chemistry: Poor crocking.

3. Resin/3D Finishes: Stiffness & Crease Retention

Resin creates a sharp, structured look and maintains creases, but comes with risks:

- Resin cracking over time.

- Reduced breathability.

- Difficult repair in laundry.

4. Coated Denim Jackets: PU/Wax Look

Coated denim looks premium—but it must be treated like a composite material. You must specify:

- Coating type (PU / Wax / Resin).

- Coating weight or hand-feel standard.

- Flex/crack resistance expectations.

- Laundering restrictions.

5. Brushed/Peached Jackets: Warmth vs. Pilling

Brushing increases warmth and softness but increases pilling risk. If your buyer expects a clean surface after wear, define pilling expectations and test method.

🧺 Washing & Garment Process Assumptions (Write Them Into the Spec)

1. Raw/Rigid Jacket Programs: What to Control

Raw jackets are “honest,” but they’re also unstable if you don’t plan them.

📋 Spec Must Include:

- Shrink and skew tolerances after an agreed wash.

- Rub-off/crocking targets.

- Consumer care instruction alignment.

- Clear approval based on post-wash measurements.

Indigo transfer is the #1 complaint in many dark denim programs. Recognized tests exist specifically to measure color transfer by rubbing.

2. Rinse/One-Wash Jackets: Safest Production Baseline

Rinse wash is the most stable baseline for commercial programs. It reduces extreme shrink surprises and makes hand feel more predictable.

💡 Strategy:

If your customer wants “not too stiff,” start here before moving to enzyme or heavy washes.

3. Heavy Wash/Distressed Jackets: Strength & Safety

Heavy wash makes jackets look great—but it’s destructive. If you want distressed effects, you must define:

- Acceptable strength loss range.

- Acceptable hole/abrasion mapping.

- Appearance tolerance (what “OK” looks like).

This is where you must think about worker safety. The denim industry has documented serious health risks linked to sandblasting processes (silica exposure and silicosis), leading to major concern and action in the industry.

Action: Don’t casually request processes that create unacceptable risk; specify safer alternatives and require compliance evidence.

4. Laundry Test Requirements Before Bulk

- Confirm your target appearance (photo + physical standard).

- Run 2–3 wash trials on bulk cuttable fabric.

- Measure shrink/skew and compare to tolerance.

- Run crocking and washing colorfastness tests.

- Approve wash recipe only after data matches appearance and tolerances.

- ISO 105-C06: Specifies methods for determining resistance of the colour to domestic or commercial laundering procedures.

- AATCC TM61: Designed to evaluate colour fastness to laundering under accelerated conditions.

🛡️ Performance Targets (Tests Buyers Should Require)

1. Dimensional Stability: Warp/Weft Shrinkage & Skew Limits

Dimensional stability is the foundation of fit and symmetry. You should state:

- Warp shrink limit.

- Weft shrink limit.

- Skew/torque limit (especially after the wash method you’ll actually use).

AATCC TM135 is intended to determine dimensional length/width changes after home laundering procedures.

2. Colorfastness: Washing, Rubbing, Perspiration, Light

Your denim jacket colorfastness requirements should always define:

- Which tests to perform.

- Dry vs wet rub requirements.

- Wash fastness requirement.

- (If relevant) Light fastness for outdoor/workwear.

ISO 105-X12 addresses colour fastness to rubbing (dry and wet).

3. Strength & Durability: Tensile, Tear, Abrasion

Here’s the key: don’t just say “strong.” This is how you convert “durable” into something enforceable in contracts:

- Tensile strength:

ISO 13934-1 describes a strip method to determine maximum force and elongation at maximum force of fabrics. - Tear strength:

ISO 13937-2 covers tear force using trouser-shaped test specimens (single tear method). - Abrasion:

ISO 12947 relates to Martindale abrasion testing (apparatus and related test methods).

4. Stretch & Recovery: Acceptable Elongation & Growth

If your jacket has stretch, you must define:

- The stretch %.

- The recovery.

- Acceptable growth after cycles.

Stretch without recovery is not comfort—it’s deformation.

5. Hardware & Trims Compatibility

Jackets use buttons, rivets, zippers, snaps. Indigo rub-off can stain pocketing or lining, and finishes can cause metal corrosion. So include:

- Trim wash test.

- Corrosion expectations.

- Staining checks.

🔍 Common Denim Jacket Fabric Defects (And How to Prevent Them in PO)

1. Barre, Streaks, and Shade Variation

These defects often come from yarn variability, dyeing inconsistency, or finishing differences. The real fix isn’t “try harder”—it’s structural.

✅ The Prevention Plan:

- Define defect types.

- Define acceptable levels.

- Define inspection rules.

- Restrict lot mixing.

2. Skewing & Torque: What to Test, How to Set Limits

Skew and torque can make panels twist after wash.

🛠️ Buyer Actions:

- Measure skew before wash and after wash.

- Define acceptable limits.

- Require corrective finishing if needed.

3. Poor Crocking: Set Grades + Finishing Fixes

Your outline might say “quality vibes,” but crocking (rub-off) is measurable. It isn’t a feeling; it’s a test score.

🧪 Standard References:

- AATCC TM8: Designed to determine the amount of color transferred by rubbing.

- ISO 105-X12: Provides a method for colour fastness to rubbing.

4. Uneven Hand Feel (Panel Mismatch): Controlling Softener & Lot Mixing

Causes: Fabric lots mixed in cutting, finishing batches differ, or softener pickup varies.

- “No mixing of finishing lots within one garment.”

- “Panels must be cut from same shade band.”

- “Softener route must match approved standard.”

5. Needle Lines & Seam Puckering

Common Causes: High tension warp + poor relaxation finishing, too stiff resin, overly heavy fabric with thin needle choice, or unstable shrink causing seam puckering after wash.

💡 Key Strategy:

This is exactly why your spec must link fabric parameters to sewing reality.

(Keyword: denim jacket sewing issues fabric causes)

📝 How to Write a Denim Jacket Fabric Specification Sheet (Template)

1. The One-Line Naming Formula

Use a one-line formula so factories and buyers speak the same language. This line prevents 70% of disputes.

“100% cotton / 3/1 twill / 12 oz (410 GSM) / warp 10S weft 12S / rope-dyed indigo / sanforized + light enzyme / 150 cm usable / rinse wash program.”

2. Detailed Specification Blocks

A. Construction Block

| Parameter | Requirement / Notes |

|---|---|

| Fiber Content | Define % with tolerance (e.g., 99% Cotton / 1% Elastane) |

| Weave Type | 3/1, 2/1, Broken Twill, etc. |

| Yarn Count | Warp/Weft (range or exact). (Internal link: Yarn Count Guide) |

| Density | EPI / PPI (if relevant for tightness control) |

| Weight | Include both oz/yd² and GSM with tolerance. |

| Width | Specify Nominal Width + Usable Width. |

B. Color & Dyeing Block

| Parameter | Requirement / Notes |

|---|---|

| Dye Method | Rope indigo / sulfur / overdye / garment dye. |

| Shade Code | Internal code or standard reference swatch. |

| Shade Control | Define shade band control rule & lot mixing restrictions. |

| Approval | Lab dip + Bulk cuttable. |

C. Finishing Block

| Parameter | Requirement / Notes |

|---|---|

| Shrinkage Method | Sanforized vs Unsanforized. |

| Softening | Softening route control requirement. |

| Coating/Resin | Coating type (PU/Wax) or Resin application. |

| Wash Suitability | Statement of use (e.g., Raw / Rinse / Vintage). |

D. Testing Block (Required Standards)

| Test Category | Standard Method | Target / Note |

|---|---|---|

| Washing Fastness | ISO 105-C06 | Define grade target. |

| Rubbing Fastness | ISO 105-X12 | Dry/Wet targets. |

| Dimensional Change | AATCC TM135 | Define method + tolerance. |

| Physical Strength | ISO Tensile/Tear/Abrasion | Define min force/cycles. |

3. Inspection & Acceptance

| Inspection System | e.g., 4-point system. |

| Defect Acceptance | Define classification and mapping rules. |

| Roll Length | Requirements for cutting efficiency. |

| Labeling | Lot number, shade band, finishing batch. |

4. Approval Workflow (Write this in the PO)

Prevent “approved in email, disputed in bulk” by enforcing this chain:

- Swatch Approval: (Initial Concept)

- Lab Dip Approval: (Color Standard)

- Bulk Cuttable Fabric Approval: (Hand feel & Production Color)

- PP Sample Approval: (Pre-Production Garment)

- TOP Approval: (Top of Production)

📋 Spec Ranges by End Use (Copyable “Spec Recipes”)

💰 Cost Drivers & Sourcing Notes (So Specs Match Budget)

1. What Increases Cost: Yarn, Dyeing, Finishing, Compliance

- Yarn: Ring-spun, slub, compact yarn = higher cost.

- Dyeing: Rope dyeing = often higher process cost.

- Finishing: Special finishing (resin/coating/brushing) = higher cost.

- Quality Control: Tight shade band and higher rejection tolerance = higher cost (but fewer claims).

Textile Exchange’s Materials Market Report tracks global fiber volumes and is used as a leading source for global fiber/material production volumes.

Why this matters: Sustainability requirements (recycled content, traceability, etc.) can change your cost structure and supplier pool.

2. MOQ, Lead Time, Sampling Plan for Jacket Programs

- Select 2–3 candidate fabrics (different weight/weave).

- Approve lab dips (or indigo depth standard).

- Sew proto samples.

- Run wash trials (2–3 recipes).

- Lock spec + tolerances + inspection.

- Approve bulk cuttable.

- Approve PP then TOP.

This plan prevents “fast approval → slow claims.”

3. Supplier Questions Checklist (To Expose Weak Factories Fast)

- ❓ What is your usable width guarantee?

- ❓ Can you control shade bands and provide lot labels?

- ❓ Which tests can you run in-house vs third-party?

- ❓ Can you replicate the exact finishing route in bulk?

- ❓ How do you prevent panel mismatch in cutting?

“Weak suppliers hate these questions. Strong suppliers answer them calmly with documentation.”

🏁 Conclusion: Turning “Feel” Into Numbers

Getting denim jacket fabric specifications right is about turning “feel” into repeatable numbers that a mill, wash house, and sewing line can execute without surprises.

🔄 The Path to Consistency

Start with the jacket type, then lock the core choices—oz/GSM weight, twill structure (3/1 vs 2/1), and fiber composition—before you move on to shade control and finishing.

Write clear tolerances for shrinkage and skew, set measurable colorfastness targets (especially dry/wet crocking), and define durability requirements like tear strength and abrasion resistance with test methods.

Enforce a simple flow—Lab dip → Bulk cuttable → PP → TOP—and prohibit lot/shade-band mixing inside a single garment.

When your denim jacket fabric specifications include these controls, you reduce claims, speed up sampling, and produce jackets that look and perform the same from first roll to last.

❓ FAQ: Denim Jacket Fabric Specifications

For most classic jackets, 10–13 oz/yd² (≈340–440 GSM) is the safest all-season range. Go lighter (8–11 oz) for soft/fashion styles, or heavier (12–16 oz) for workwear.

Use 3/1 twill for classic structure and a traditional denim look. Use 2/1 twill when you want a softer hand and more drape (often for fashion/oversized jackets).

100% cotton is best for structure and heritage feel. If comfort matters, add 1–2% elastane and specify recovery targets to prevent elbow bagging.

A common commercial target is ≤3% warp and ≤3% weft after the agreed wash method. Lined/sherpa jackets usually need tighter control and system testing (shell + lining).

The critical one is crocking (rubbing fastness)—both dry and wet—because indigo can transfer to skin, tees, and lining. Also specify washing fastness and, for workwear/outdoor, light fastness.

Use shade band control + lot control: approve lab dips, then approve bulk cuttable fabric, prohibit mixing lots within one garment, and require roll labeling by shade band.

Prioritize tear strength + abrasion resistance + seam durability, then choose heavier weights (often 12–16 oz) and avoid over-softening finishes that reduce strength.

At minimum: fiber %, weave, oz/GSM, yarn count, width/usable width, dye method, finishing, shrinkage & skew tolerances, colorfastness targets, strength tests, inspection rules, approval steps.

It’s best if you want strong fade character, but it often increases crocking risk. If you choose it, set stricter rubbing targets and define wash/finishing controls.

When you want a wax/PU fashion look. Specify coating type, crack resistance expectations, care rules, and accept tradeoffs in breathability and long-term wear.