🧵 Introduction: Specifying the “Right” Denim?

If you are specifying the fabric for mass-produced denim shirts, then denim shirt fabric specifications become extremely important.

⚖️ The Best Specs Balance These 4 Factors:

- 🔹 Breathability & Skin Comfort: Handfeel is the first purchasing decision customers make.

- 🔹 Dimensional Stability: Tightly controlling Shrinkage + Skewing (torque) so side seams don’t twist after the first wash.

- 🔹 Panel Matching: Strict Shade Band Control to ensure the left front, right front, and sleeves look like they came from the same roll.

- 🔹 Crocking Control: Managing color transfer (dry/wet rub) to acceptable limits.

⚠️ Why This Matters

Without these controls, collars, cuffs, yokes, pockets, and plackets don’t just fail inspection—they turn into a returns factory after the customer washes them.

Start With Shirt Type & Construction

(because collar, yoke, and placket change the spec)

Before you pick weight or fiber, start with shirt construction. Shirt components create panel-matching risks that jeans don’t have.

🤠 Western shirt (snap buttons, yoke, chest pockets): panel matching and crocking risk

A western denim shirt has a lot of “symmetry traps”:

- left/right pockets must match

- yoke must match the body

- placket must not look like a different shade

- collar and cuffs get the most rubbing (crocking)

📋 What changes in the spec (step-by-step):

- 🔹 Add a shade band control rule: no mixing shade bands within one garment.

- 🔹 Define a panel cutting rule: cut yoke + body from the same shade band/lot when possible.

- 🔹 Set rubbing (crocking) targets: specifically with collars/cuffs in mind. (Internal link: Colorfastness Guide.)

- 🔹 Approve a “bulk cuttable” standard: not just a hand swatch. Denim shirts can look perfect in swatches and fail when you spread panels across multiple rolls.

🧥 Overshirt / shirt jacket (heavier): when you can borrow jacket logic—and when you can’t

You can borrow some weight logic from a jacket when you’re building an overshirt, but don’t copy everything.

✅ What you can borrow:

- Heavier weight range

- Stronger seam behavior expectations

- More tolerance for stiffness

🛑 What you must keep “shirt-first”:

- Collars/cuffs rubbing risk

- Panel matching (yoke/pockets/placket)

- Skin comfort (neck/cuff irritation matters more than on jackets)

🌬️ Chambray-style denim shirts: why it behaves differently from true denim

Chambray is often used for “denim-look shirts” because it can feel cooler and cleaner.

💡 Practical buyer translation:

- 🔹 Chambray often gives you breathability + a cleaner surface.

- 🔹 Twill denim gives you stronger diagonal texture + more traditional denim appearance.

- 👉 If your customer wants a “classic denim diagonal,” specify twill. If they want a light, airy shirt that still looks denim-adjacent, chambray is often safer.

🎨 Garment-dyed denim shirts: style wins, but shade and shrink risks increase

Garment dyeing is a fashion weapon—but it can produce:

- Higher shade variation

- Higher shrink and fit drift

- More staining risk depending on dye route and after-wash

⚠️ Spec rule: If it’s garment dyed, write tighter approval and shade standards (lab dip/standard + wash baseline + bulk cuttable approval).

Recommended Weight (oz/GSM) for Denim Shirts

— by season and transparency risk

The biggest denim-shirt mistake is thinking “more oz = better quality.” Shirts need comfort and stability, not armor.

☀️ Lightweight range (summer): how to stay breathable without going sheer

Typical target: 3.8–5.5 oz/yd² (≈ 130–185 GSM)

🕵️♀️ How to avoid transparency (step-by-step):

- 🔹 Don’t chase weight only: request construction density (warp/weft ends and picks).

- 🔹 Choose 2/1 twill or chambray for a cleaner surface and better drape.

- 🔹 If using dark indigo, control crocking so it doesn’t stain light pants. (Internal link: Colorfastness Guide.)

- 🔹 Approve the fabric under daylight and store lighting: lightweight denims can surprise you in bright retail environments.

⚖️ All-season range: the safest commercial band for retail shirts

Typical target: 5.5–7.5 oz/yd² (≈ 185–255 GSM)

This is the “least regret” band for:

- Western shirts

- Work shirts (light-to-mid)

- Overshirt-lite

🧥 Heavy “overshirt” range: when it makes sense and when it backfires

Typical target: 7.5–10 oz/yd² (≈ 255–340 GSM)

This works when your shirt is basically an outer layer. But it backfires when:

- Collars feel too stiff at the neck

- Cuffs rub and irritate skin

- Customers complain it “wears like a jacket, not a shirt”

🚫 Why shirt weights differ from jeans and jackets (common buyer mistakes)

Jeans are abrasion-first; jackets are structure-first; shirts are comfort + stability + panel matching.

⚠️ Common mistake:

Copying jean weights (10–14 oz) into shirts and then “fixing comfort” with heavy softener. That often creates:

- Inconsistent handfeel roll-to-roll

- Seam puckering

- Higher pilling risk if brushing is used

Weave & Structure (the “shirt handfeel engine”)

This is where denim shirts are won or lost: the weave influences softness, drape, and how the shirt behaves after washing.

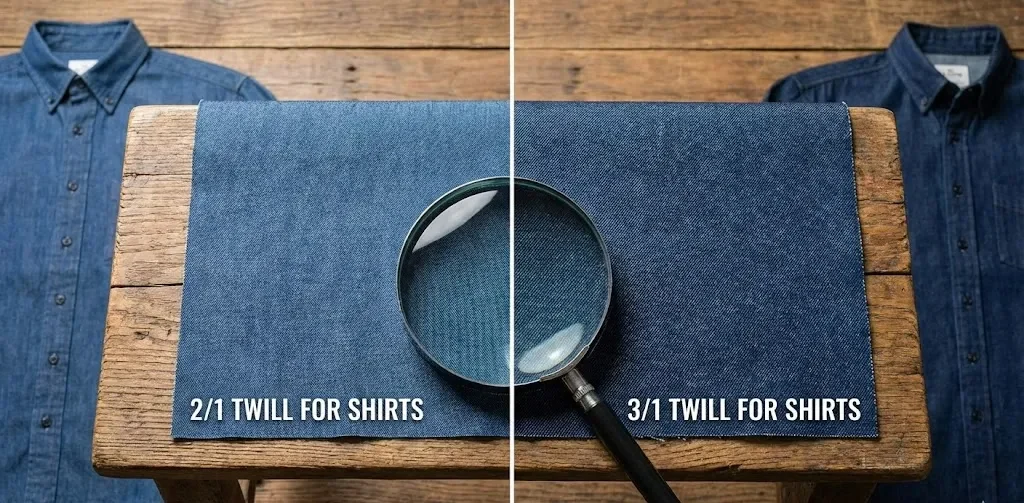

2/1 vs 3/1 twill for shirts: softness, drape, and cost

Here’s the buyer-friendly comparison:

| Item | 2/1 twill (common for shirts) | 3/1 twill (classic denim look) |

|---|---|---|

| Handfeel | often softer at low weights | can feel more “denim-authentic” |

| Drape | usually better drape | can feel stiffer at the same GSM |

| Appearance | cleaner diagonal | stronger traditional diagonal |

| Risk | too soft if over-finished | stiffness at collar/cuffs if too heavy |

If you want to cite a neutral weave definition, denim is a warp-faced twill; the diagonal rib comes from the twill structure.

🧵 Chambray vs denim: warp/weft color, texture, and comfort differences

💡 Simple rule:

- Chambray often feels cooler and lighter for shirts

- Twill denim looks more “classic denim” and has the diagonal rib

👉 When you’re writing the spec, don’t just write “denim.” Write “denim twill” or “chambray” and then define weight + density.

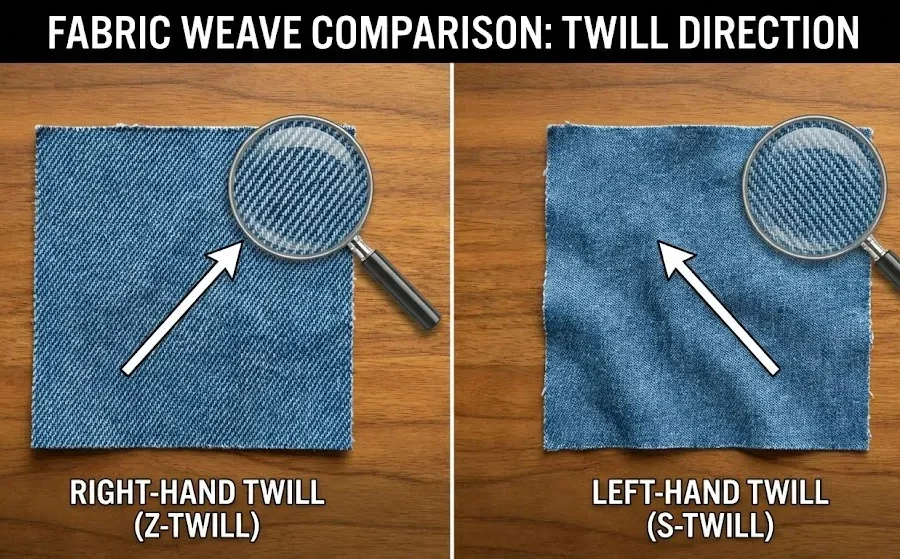

🧶 Right-hand vs left-hand twill: softness vs surface hairiness

At shirt weights, twill direction can influence:

- Perceived softness

- Surface fuzz/hairiness

- How quickly cuffs and collars look worn

✅ If your program is skin-comfort sensitive (neck irritation complaints), consider smoother yarn and finishing before you obsess over twill direction.

⚠️ Slub/crosshatch for shirts: premium texture vs “defect” disputes (how to write acceptance)

Slub can look premium—but only if you define acceptance.

📝 How to write it so it’s not a fight (step-by-step):

- 🔹 Approve a reference swatch with the intended slub look.

- 🔹 Write: “slub effect is intentional; barre/streaks beyond approved standard are not acceptable.”

- 🔹 Define what “beyond standard” means (frequency, visibility from distance, panel impact).

- 🔹 Add inspection language (4-point + mapping if needed).

🔗 mention defect acceptance rules, link to [Fabric Defects].

Fiber Composition

(how to hit softness and breathability without losing stability)

Fiber is not just about marketing; it’s about how the shirt behaves after wash and wear.

☁️ 100% cotton: crisp look, but how to avoid stiffness and shrink surprises

✅ Pros (1–3):

- Classic denim look and fade potential

- Good structure for collars/yokes

- Easier to position as “authentic denim”

❌ Cons (1–3):

- Can feel stiff at shirt weights if finishing is not tuned

- Shrink and skew can surprise you if wash baseline isn’t written

- Crocking risk is real on deep indigo

📋 Practical spec moves:

- 🔹 Require post-wash shrink/skew limits (don’t leave it vague).

- 🔹 Control crocking.

- 🔹 Use finishing to soften within limits, not by “over-softening” bulk.

🌿 Cotton–Tencel/Lyocell blends: softness and cooling, but manage seam durability

✅ Pros:

- Noticeably softer, cooler handfeel

- Better drape for fashion shirts

- Can reduce “scratchy neck” complaints

❌ Cons:

- If too soft, seam behavior and shape retention can suffer

- Can highlight panel mismatch because drape makes shade differences more visible

- May need tighter lot control to keep bulk consistent

💡 PO tip: When you use blends for softness, write seam and stability expectations clearly so the factory can’t hide behind “it’s supposed to be soft.”

🧪 Cotton–poly blends: quick dry and stability, but handfeel and fade tradeoffs

✅ Pros:

- More dimensional stability

- Quicker dry and often better wrinkle recovery

- Easier bulk repeatability in some programs

❌ Cons:

- Changes fade behavior and “authentic denim” storytelling

- Can feel less natural on skin if not finished well

🧘♀️ Stretch in shirts: when it’s unnecessary—and when a small % helps comfort

Most denim shirts do not need stretch. But a small % can help for fitted silhouettes.

📏 Rule of thumb:

- If the shirt is tailored and size tolerance is tight, a small comfort stretch can reduce “tight back/shoulder” complaints.

- If it’s a classic western shirt, stretch can complicate panel matching and stability unless you control it well.

Factory floor story

🚩 The Complaint

On one western denim shirt program, we had a buyer approve the lab dip and a hand swatch quickly—then bulk complaints came back: the yoke looked slightly different from the body, and customers reported collar/cuff staining on light undershirts.

🔍 Here’s exactly how we solved it

We stopped debating and recreated the complaint. We cut a few sample shirts using panels from different rolls that were “within color tolerance” on paper. Under retail lighting, the yoke mismatch became obvious.

Root Cause Identified:

The program had no usable shade band control rule and no panel cutting discipline for yoke/pockets. The factory was mixing rolls to improve cutting efficiency.

🛠️ We negotiated a fix with the buyer

- 🔹 Explained the trade-off: We explained clearly that strict shade band control can increase cutting constraints (and reduce marker efficiency), but it prevents visible mismatch. The buyer agreed to accept the small efficiency impact.

- 🔹 Locked it into the PO: Roll labeling by lot + shade band, and a strict rule that yoke/pocket panels must be cut from the same shade band as the body panels.

- 🔹 Added staining controls: We added method-based crocking targets and required re-testing after finishing (softener and enzyme routes can change rubbing transfer). We used ISO 105-X12 as the standard for rubbing fastness.

✅ The Result

We re-approved “bulk cuttable” fabric (not swatches), and only then proceeded to PP and TOP.

This one change (shade band rules + crocking control) eliminated the mismatch and staining complaints in the next production run.

Yarn Specs

(count, spinning, and why shirts “feel” scratchy or smooth)

Denim shirts touch skin at the neck, cuffs, inner placket, and yoke seams, so yarn choice affects comfort more than most buyers expect. If you’ve ever had a denim shirt that looked great but felt “itchy” around the collar, that’s usually a yarn + finishing interaction—not “bad sewing.”

Yarn count ranges by weight (shirt edition)

Use this table as a practical starting point. It is intentionally “range-based” because mills use different constructions to reach the same GSM.

| Shirt program | Typical weight | Warp yarn (Ne) | Weft yarn (Ne) | Why this range works |

|---|---|---|---|---|

| Summer / lightweight shirts | 3.8–5.5 oz (130–185 GSM) | 16–30 Ne | 16–30 Ne | Higher counts keep it smooth and breathable |

| All-season retail shirts | 5.5–7.5 oz (185–255 GSM) | 10–20 Ne | 10–20 Ne | “Least regret” balance of handfeel + stability |

| Workwear shirts / overshirt-lite | 7.5–10 oz (255–340 GSM) | 7–12 Ne | 7–12 Ne | Lower counts add durability without extreme stiffness |

📝 How to write it in the PO (step-by-step, so it’s enforceable)

- 🔹 Write warp/weft yarn count as a range or a target + tolerance (example: “Warp 12 Ne ±1, Weft 10 Ne ±1”).

- 🔹 Add spinning method requirements if you care about the surface: ring-spun, open-end, combed, compact, etc.

- 🔹 Confirm the mill reports yarn count in the same system (Ne vs Nm); don’t assume.

🌀 Ring-spun vs open-end: texture, hairiness, and comfort on skin

💡 A buyer-friendly way to think about it:

- Ring-spun tends to produce a more “premium” surface for shirts—often smoother and more comfortable at the collar/cuffs (at comparable finishing).

- Open-end (OE) can be cost-effective and durable, but can also feel hairier/rougher on skin if finishing is not tuned.

The trick is not to treat this as ideology.

Treat it as a handfeel + pilling + crocking risk decision: A hairier surface can sometimes increase perceived crocking transfer (more dye on the surface to rub off), depending on dye route and finishing.

✨ Combed/compact options: when they actually reduce irritation and pilling

For denim shirts, combed/compact choices matter most when:

- You’re selling a “soft against skin” promise

- You’re doing brushing/peaching, which can magnify pilling if the base is unstable

📏 A practical rule: If you plan heavy softening or brushing, your base yarn and construction need to be more stable, not less—otherwise you’ll trade short-term softness for long-term pilling complaints.

🔗 Related Guides:

When you introduce yarn count ranges and what “Ne” means, insert the internal link: [Yarn Count Guide].

Dyeing, Crocking, and Shade Control

(shirts stain other clothes more easily)

Shirts are high-contact garments: collars rub necks, cuffs rub wrists, and the front placket rubs against belts/bags. That’s why denim shirts often generate more “staining” complaints than denim jackets—especially in dark indigo.

👖 Rope-dyed indigo: best fade, but higher crocking risk on collars/cuffs

Rope-dyed indigo is popular because it builds the classic fade character. But for shirts, you must assume higher crocking risk on:

- Collar edges

- Cuffs

- Pocket edges

- Placket folds

📝 How to write crocking control into your spec (step-by-step):

- 🔹 Choose your method: ISO 105-X12 or AATCC TM8 (don’t leave it vague).

- 🔹 State dry and wet requirements: (both matter for shirts).

- 🔹 State the test condition and evaluation scale: (your lab will standardize this).

- 🔹 Require testing after finishing: (and after garment wash baseline if garment-washed).

- 🔹 Add a “high-contact zones” note: if the shirt is dark indigo, collars/cuffs must meet the same requirement.

🌑 Sulfur colors (black/gray): undertone drift and batch control

Black/gray denim shirts (often sulfur dyed) can trigger complaints like:

- “It looks greenish/warmer than the approved sample”

- “The collar looks like a different black than the body”

✅ What prevents this in bulk is not luck—it’s batch and shade discipline:

- Define your shade standard (approved reference)

- Define the lot/shade band rules

- Define approvals at “bulk cuttable” stage

🎨 Overdye/garment dye: fashion-first, higher shade variance

Garment dyeing is a style lever, but the cost is risk:

- Higher shade variance across garments

- Higher shrink/fit drift

- Higher chance of staining other garments (depending on wash/after-treatment)

⚠️ Spec Rule: If it’s garment dyed, your approval flow must be stricter (bulk cuttable and PP approval become non-negotiable).

⚖️ Shade band rules for shirt panels: yoke, placket, pocket symmetry

Shirts have “symmetry panels” that make slight differences look big:

- Yoke vs Body

- Left pocket vs Right pocket

- Left placket edge vs Right placket edge

- Collar stand vs Collar

📋 PO-ready shade band rule (copy-paste):

“Rolls must be labeled by lot and shade band. No mixing shade bands within one garment. Symmetry panels (yoke + pockets + placket) must be cut from the same shade band.”

Finishing

(how to get softness without killing strength or causing puckering)

Finishing is where denim shirts either become “premium comfortable” or “complaint bait.” The biggest buyer mistake is asking for “very soft” without guardrails—then being surprised by puckering, pilling, or unstable bulk.

📏 Sanforized vs unsanforized: what shirt buyers should require

For most commercial denim shirts, sanforization (or an equivalent pre-shrink control) is the safer baseline because shirt fit is sensitive, especially at collars and cuffs. You don’t need to sell “raw authenticity” the way jeans do; you need repeatable sizing.

🧪 Softening and enzyme finishing: comfort gains vs strength loss

Enzyme and softening routes can be fantastic—but they’re not free:

- Too aggressive → strength loss and early wear

- Too much softener → seam puckering and panel handfeel inconsistency

- Inconsistency roll-to-roll → “some shirts feel different in the same carton”

📝 How to specify it (step-by-step):

- 🔹 Write “soft handfeel” as an approval standard, not a vague requirement.

- 🔹 Require handfeel to match your approved reference sample within the same finishing route.

- 🔹 Cap or control the finishing route if your brand is sensitive to pilling or seam problems.

🧶 Brushing/peaching: warmer handfeel vs pilling risk

Brushed denim shirts feel great, especially in fall collections—but brushing can increase:

- Pilling complaints

- Fuzzy surface that transfers dye more easily

⚠️ If you brush, your spec should tighten:

- 🔹 Pilling expectations: (method-based).

- 🔹 Crocking control: (because surface change matters).

👔 Resin/stiff finish: when it helps collars and plackets—and when it cracks

Resin can help collars/plackets keep shape, but for shirts it can backfire:

- Cracking at fold lines after laundering

- “Boardy” collar feel

- Unnatural drape

✅ A safer approach is usually: Design + Interlining choice + Moderate finish (instead of “hard-resin everything”).

A real production situation we solved

(first-person, finishing + seam puckering)

🚩 The Complaint

On a denim shirt program for a retail buyer, the first bulk run came back with a complaint: the front placket looked wavy and some cartons felt softer than others. The sewing team blamed the fabric; the buyer blamed the sewing; both were partially right.

🔍 Here’s what we did, step by step

We pulled rolls from multiple finishing lots and measured shrink and skew under the buyer’s intended wash baseline (not just greige).

Root Cause Identified:

We found the real cause: the mill had adjusted softener dosage slightly between lots to match handfeel, but that changed how the fabric fed under the presser foot and how the placket behaved after wash.

🛠️ The Fix & Verification

- 🔹 Aligned on a single finishing window: Instead of chasing “as soft as possible,” we agreed on “soft enough” plus stability.

- 🔹 Added a PO line: “Softening route must match approved reference; softener and enzyme parameters must not change without buyer approval.”

- 🔹 Ran a quick factory trial: Same sewing line, same operator, three fabric lots—only the finishing window changed. The placket wave disappeared when finishing was controlled.

✅ The Lesson

This is why finishing must be written as an auditable system, not a mood.

Garment Wash Assumptions

A denim shirt’s final behavior is often decided by the wash route. If the buyer says “we’ll decide later,” your spec becomes meaningless.

👖 Raw/rigid shirts: shrink, twist, and crocking expectations

Raw shirts are niche but real. If you produce raw/rigid shirts:

- You must warn about shrink and twist

- You must define crocking expectations (raw indigo can stain)

📝 Write it plainly:

“Raw shirt may crock during early wears; customer care labeling and pre-production testing required.”

💧 Rinse/one-wash shirts: the most stable commercial baseline

If you want repeatability in bulk, rinse/one-wash is the “safest commercial baseline” for:

- Fit stability

- Reduced surprise shrink

- Easier QC comparisons

⚠️ Enzyme/stone wash shirts: strength loss and appearance tolerances

If you stone wash or enzyme wash shirts, specify:

- Acceptable shade variance

- Acceptable surface texture

- Acceptable strength loss risk (at least acknowledge it in approvals)

🧪 Pre-production wash test requirements (to prevent wash-house damage)

This is one of the highest-ROI steps you can add.

📋 Step-by-step (buyer-friendly):

- Approve fabric and finishing reference first.

- Cut a small set of panels representing critical areas: collar, cuff, yoke, placket, pocket.

- Run the intended wash route at the wash house.

- Measure shrink/skew and visually inspect symmetry panels for mismatch.

- Re-test crocking if the surface changed meaningfully.

- Only then approve PP → TOP.

💡 Note: For shrink and dimensional change under home laundering conditions, many programs reference AATCC TM135.

Performance Targets

(shirts are about skin comfort + stability + seam behavior)

For denim shirts, the “shirt-specific” performance pain points are:

- Shrink + skew (collars and plackets reveal it fast)

- Crocking transfer (staining complaints)

- Seam behavior (puckering, slippage, distorted plackets)

- Pilling (especially on brushed/softened shirts)

📏 Dimensional stability: shrink and skew limits for shirts

PO rule: never write shrink limits without the method/baseline. AATCC TM135 is commonly used for dimensional change under home laundering procedures.

📋 Practical target approach (how buyers avoid fights):

- 🔹 Set warp/weft shrink tolerances tied to your wash baseline.

- 🔹 Add skew/torque observation and tolerance if your brand is fit-sensitive.

- 🔹 Require reporting after wash + dry, not just after wash.

🎨 Colorfastness: wash + rubbing (dry/wet) targets to avoid staining

For shirts, rubbing (crocking) is often more complaint-driving than wash fastness because the shirt rubs other garments and skin.

Relevant methods include ISO 105-X12 and AATCC TM8 for color transfer by rubbing (dry and wet).

🧵 Seam slippage and seam puckering: the shirt-specific pain points

Denim shirts have visible seams at:

- Placket folds

- Yoke join

- Collar stand

- Cuffs

⚠️ Even small seam issues become visually loud. Your spec should include:

- 🔹 A seam behavior expectation (no excessive puckering after approved wash).

- 🔹 Construction assumptions (needle size and stitch density aligned to fabric).

🧶 Pilling risk: when brushing/softening increases complaints

If you brush or heavily soften, add pilling expectations and approval checks:

- Approve against reference after wash

- Confirm collar/cuff surface is acceptable (that’s where customers notice)

Common Denim Shirt Defects

(and how to prevent them in the PO)

Denim shirts fail in bulk for a very specific reason: shirts have “visible symmetry” parts (yoke, pockets, placket, collar/cuffs). Small issues that might be “tolerable” in jeans turn into obvious defects on a shirt front.

When you talk about defects and acceptance rules, link internally to [Fabric Defects].

🧩 Uneven shade / panel mismatch: yoke, pockets, and placket alignment rules

👀 What buyers see:

- Yoke looks slightly lighter/darker than the body

- Left pocket doesn’t match right pocket

- Placket edge looks like a different roll

🔍 Root causes (most common):

- Shade bands mixed within one garment

- Cutting symmetry parts from different lots

- Finishing variation between rolls

- Inspection focused on swatches, not “bulk cuttable”

📝 PO prevention (copy-paste rules):

- 🔹 Shade band control: “Rolls must be labeled by lot + shade band. No mixing shade bands within one garment.”

- 🔹 Symmetry cutting rule: “Yoke + pockets + placket must be cut from the same shade band as the front body panels.”

- 🔹 Approval rule: “Bulk cuttable approval required (not only lab dip / hand swatches).”

- 🔹 QC check: add a panel-match checkpoint at cutting (before sewing hides it).

🏭 Practical QC step-by-step (factory-friendly):

- Spread the front body panels for 5–10 garments side-by-side under consistent lighting.

- Place the yokes and pockets on top of the fronts (no sewing).

- If mismatch is visible at arm’s length, stop and re-sort by shade band.

- Record lot/shade band used for each cutting batch for traceability.

🎨 Collar/cuff crocking: root causes and acceptance criteria

For shirts, crocking isn’t academic—collars/cuffs touch skin and rub against light inner layers. Denim that looks perfect can still fail when rubbing transfer is high.

Relevant method references include ISO 105-X12 (dry and wet rubbing) and AATCC TM8 (color transfer by rubbing, dry and wet).

🔍 Root causes:

- Surface dye sitting on the face (especially deep indigo)

- Finishing route increases surface fuzz (brushing/peaching)

- Test was done on greige or pre-finish fabric, not final finished baseline

📝 PO prevention (copy-paste structure):

- 🔹 “Crocking to meet ____ standard method (ISO 105-X12 or AATCC TM8), dry and wet.”

- 🔹 “Test after final finishing (and after garment wash baseline if garment washed).”

- 🔹 “High-contact zones (collar/cuffs) must meet the same requirement.”

✋ Handfeel inconsistency: softener control and lot mixing rules

👀 What buyers see:

- Same style, same carton… but some shirts feel softer/hairier

- Collars feel scratchy on some garments only

🔍 Root causes:

- Softener/enzyme parameters changed between finishing lots

- Lots mixed to improve cutting efficiency

- Brushing intensity not controlled lot-to-lot

📝 PO prevention:

- 🔹 “Finishing route must match approved reference; no parameter changes without buyer approval.”

- 🔹 “No lot mixing within one PO delivery batch without written approval.”

- 🔹 “If brushed/peached, brushing intensity and pilling risk must be validated on PP.”

🧵 Sewing problems: needle damage, puckering, and skipped stitches

Denim shirts show sewing problems clearly at plackets, collars, yokes, and pocket edges.

🔍 Common fabric-driven causes:

- Fabric too stiff for placket folding → waviness/puckering

- Surface too fuzzy → feeding problems and skipped stitches

- Shrink/skew not controlled → seam distortion after wash

🛠️ Spec + process fixes (step-by-step):

- Confirm your wash baseline and shrink/skew controls before PP. (Dimensional change under home laundering is commonly evaluated with AATCC TM135.)

- Align needle size and stitch density with fabric weight (don’t “guess” from a past style).

- Require a short sewing trial on PP with collar + placket + cuff pieces (the real failure zones).

- Re-check placket straightness and collar shape after the intended wash route.

Width, Usable Width, and Cutting Efficiency

(shirt markers behave differently)

Shirts are more sensitive to width than many buyers realize because symmetry pieces (yokes, pockets, collars) amplify cutting constraints. Always specify cuttable (usable) width, not only nominal width.

📏 Typical widths for denim shirts and how to confirm usable width

Typical finished nominal widths are often in the 150 cm / 160 cm family, but what matters is cuttable width after edge defects and finishing variability.

📋 Step-by-step confirmation process:

- 🔹 Ask the mill for nominal width AND cuttable width.

- 🔹 Require width testing after finishing (and after garment wash baseline if garment washed).

- 🔹 Define how edge defects are handled: “Edges with defects are excluded from cuttable width.”

✂️ Shrink allowance and how it changes marker planning

If your fabric shrinks, your marker plan must account for it—especially for collar/cuff precision.

✅ Marker planning checklist:

- Confirm post-wash width change

- Confirm skew/torque impact

- Confirm whether symmetry parts must be cut from the same shade band (this can reduce marker flexibility)

👖 Narrow width/selvedge shirts: when it’s a story vs when it’s a headache

Narrow or selvedge denim can be a marketing story, but for shirts it can also:

- Increase fabric consumption

- Complicate symmetry cutting

- Increase risk of panel mismatch if yield pressure encourages lot mixing

⚠️ If you do it, write the rules explicitly: “No shade mixing; symmetry parts from same shade band; marker efficiency impact accepted.”

How to Write a Denim Shirt Fabric Spec Sheet (PO Template)

(factory-friendly structure to prevent disputes)

This is the “factory-friendly” PO structure that prevents most bulk disputes. Use it exactly like a form.

📝 One-line naming formula (shirt version)

Formula:

Weight + weave + fiber + warp/weft yarn count + finished cuttable width + finishing + wash baseline + test targets + shade band rules

Example (fill in your values):

“__ oz / __ GSM denim (2/1 twill), fiber __%, warp/weft yarn count / (see [Yarn Count Guide]), cuttable width __ cm, sanforized + enzyme/softener (approved route), wash baseline __, shrink %/%, crocking dry/wet to __ standard, shade band control: no mixing within garment.”

Structure block: fiber, weave, yarn count, density, weight, width

| Item | What to write | Why it matters |

|---|---|---|

| Fiber content | % breakdown | Drives comfort, stability, fade behavior |

| Weave/structure | chambray / 2/1 / 3/1 | Drives handfeel and drape |

| Yarn count | warp/weft (and method) | Drives surface comfort + consistency (link [Yarn Count Guide]) |

| Weight | oz/yd² and GSM | Prevents “same name, different cloth” surprises |

| Width | nominal + cuttable | Prevents marker/cost disputes |

🎨 Color block: dye method, shade standard, shade band rules

Include:

- Dye method (rope-dyed indigo / sulfur / garment dye)

- Shade standard (approved reference)

- Shade band rules (no mixing within garment; symmetry panel rule)

✨ Finish block: sanforization, softening, brushing, resin limits

Write finishing as a controlled route:

- Sanforized (yes/no)

- Enzyme/softener route locked to approved reference

- Brushing/peaching (if any) with pilling/crocking considerations

- Resin/stiff finish only where needed, with cracking risk acknowledged

🧪 Test block: shrink/skew, crocking, seam behavior, pilling

This is where you prevent vague arguments.

- 🔹 Dimensional change: AATCC TM135 is commonly used for home laundering dimensional change evaluation.

- 🔹 Rubbing fastness (crocking): ISO 105-X12 and AATCC TM8 are widely used method references for rubbing transfer (dry and wet).

💡 Note: You don’t need to publish every numeric target in the article—just show buyers how to write method + target + condition so it’s enforceable.

🧐 Inspection & acceptance: 4-point, defect definitions, labeling

Include:

- 4-point inspection requirement

- Major/minor defect definitions

- Roll labeling: lot + shade band + cuttable width

- Traceability rule: cutting batches recorded

✅ Approval flow: lab dip → bulk cuttable → PP → TOP

For denim shirts, bulk cuttable is the key checkpoint because it catches:

- Panel mismatch

- Handfeel lot variation

- Shade band issues that don’t appear in swatches

Spec Recipes by End Use

These “recipes” are deliberately practical—buyers can copy/paste and then adjust.

🤠 Western retail denim shirt recipe (balanced + classic)

- 🔹 Weight: 5.5–7.5 oz (185–255 GSM)

- 🔹 Structure: 2/1 twill (or light 3/1)

- 🔹 Fiber: 100% cotton (or cotton/lyocell for softness)

- 🔹 Cuttable width: confirm and write it

- 🔹 Shrink: write warp/weft targets tied to wash baseline (AATCC TM135 as method reference if needed)

- 🔹 Crocking: specify method + dry/wet (ISO 105-X12 or AATCC TM8)

- 🔹 Shade: no mixing within garment; symmetry parts same shade band

☀️ Lightweight summer denim shirt recipe (breathable + not sheer)

- 🔹 Weight: 3.8–5.5 oz (130–185 GSM)

- 🔹 Structure: chambray or 2/1 twill

- 🔹 Fiber: cotton/lyocell blend for cooling (watch seam behavior)

- 🔹 Risk control: transparency and crocking (dark indigo can stain)

🌿 Soft lyocell-blend denim shirt recipe (cooling + drape)

- 🔹 Weight: 4.5–6.5 oz (150–220 GSM)

- 🔹 Structure: 2/1 twill

- 🔹 Finish: controlled enzyme + softener window (locked to approved reference)

- 🔹 QC: confirm handfeel consistency roll-to-roll; don’t allow lot mixing

🛠️ Workwear denim shirt recipe (durable but wearable)

- 🔹 Weight: 7.5–10 oz (255–340 GSM)

- 🔹 Structure: 3/1 or sturdy 2/1

- 🔹 Fiber: 100% cotton or cotton/poly (stability priority)

- 🔹 Focus: seam behavior + dimensional stability + controlled finishing (avoid “over-softening”)

Cost Drivers and Sourcing Notes

(make the spec fit your budget)

If buyers want a reliable bulk program, they must understand which spec decisions raise cost—and which “savings” create hidden claims later.

💰 What increases cost: yarn quality, dye control, finishing, testing, compliance

High-impact cost drivers:

- Higher-grade yarn (combed/compact, tighter consistency)

- Stricter shade band control (less cutting flexibility)

- Tighter dimensional stability controls (more process discipline)

- Brushing/peaching plus pilling control

- Additional testing and approvals (bulk cuttable, PP trials)

📊 Industry data context (why fiber choice matters):

Textile Exchange’s Materials Market Report is a widely referenced source for global fiber and materials production volumes and trends—useful when you explain why certain blends, certifications, or raw material constraints affect price and lead times.

⏱️ MOQ, lead time, and sampling cadence for shirt programs

A practical, low-drama cadence:

- Lab dip / shade approval

- Bulk cuttable approval

- PP sample (with collar/placket/cuff validation)

- TOP sample

- Bulk production

⚠️ Skipping bulk cuttable is where buyers “save time” and then lose weeks on claims.

❓ Supplier questions that reveal weak mills fast

Ask these early:

- 🔸 “How do you label and manage shade bands across rolls?”

- 🔸 “What is your standard crocking performance for deep indigo shirts, dry and wet, and what method do you use?”

- 🔸 “How do you control softener/enzyme parameters across lots?”

- 🔸 “Can you report cuttable width and post-finish width change?”

- 🔸 “Can you run a bulk cuttable approval yardage for panel matching?”

🚫 Compliance sidebar: why certain distress processes are risky (industry case)

If your shirt design includes heavy distressing, include a “restricted processes” note. A well-known industry example is the global ban on sandblasting announced by Levi Strauss & Co. and H&M due to worker health risks.

Research on silicosis among denim sandblasters is documented in peer-reviewed medical literature, reinforcing why brands moved away from this technique.

📝 How to write it in your PO (simple and enforceable):

“Restricted processes: sandblasting is prohibited. Any distress alternatives require buyer approval and documented process controls.”

That’s not “extra.” That’s risk management.