Introduction: Your Roadmap to Cotton Fabric Sourcing Guide

Sourcing cotton fabric might seem straightforward, but as professionals know, the devil is truly in the details. Incorrect specifications, unreliable suppliers, ambiguous contracts… a misstep at any stage can lead to significant cost overruns, quality disasters, and ultimately, failed product launches. This guide is designed to provide you with a clear roadmap, whether you are conducting your first cotton sourcing project or seeking to optimize an established process.

Our Factory Experience & Expertise

We are a textile team focused on production, specializing in developing and supplying cotton fabrics for apparel and home textile brands for the past 20 years. Our daily work goes far beyond simply selling cloth. We engage in practical development meetings with buyers, meticulously source specific yarn qualities, conduct crucial lab tests for shrinkage (AATCC TM135 / ISO 6330) and colorfastness (ISO 105 series), and troubleshoot bulk quality issues before goods ever leave our factory.

This guide is built upon the hard-won lessons from thousands of actual orders, not just abstract theory. When we emphasize specifying tolerances or verifying certifications, it’s because we’ve witnessed firsthand the significant financial and reputational damage that occurs when these steps are overlooked.

👉 Why This Matters to You:

You’re not reading a classroom summary; you’re getting the same operational playbook we provide to first-time buyers to prevent them from wasting money on their initial bulk orders.

Step 1: How to Choose the Right Cotton Fabric

Selecting the right material is the cornerstone of a successful product. Here are the key indicators you need to evaluate when choosing cotton fabric.

Understanding Key Quality Indicators

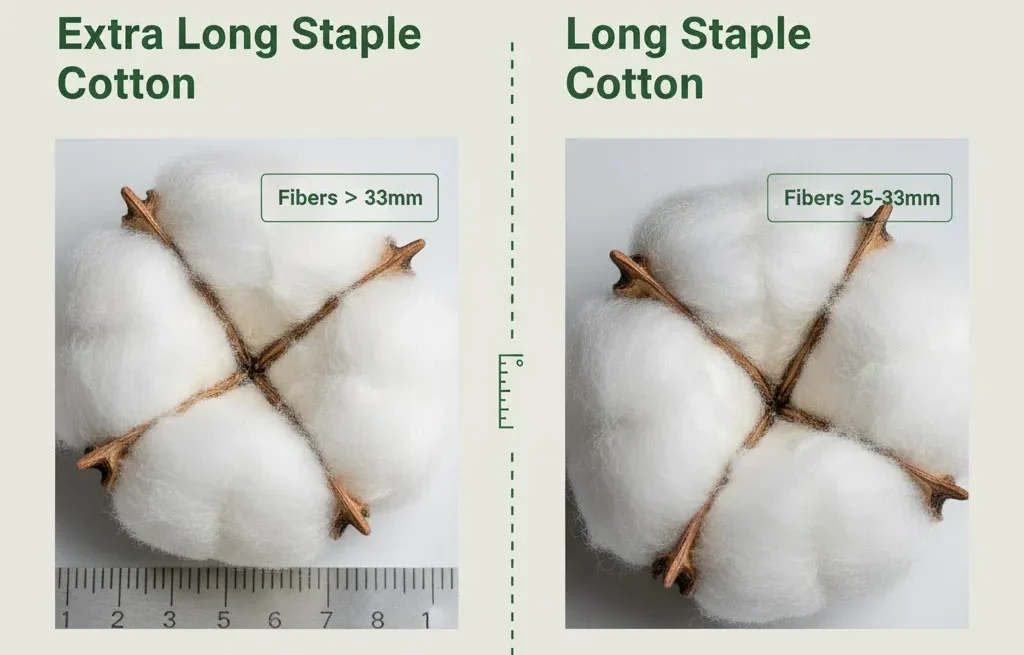

Fiber Quality (Staple Length):

The length of the individual cotton fibers is the most fundamental determinant of quality.

- Key Distinction: Extra-Long Staple (ELS) cottons like Pima and Egyptian typically have fibers over 33mm, while standard Upland cotton ranges from 25-31mm.

Impact on Sourcing:

- Strength: ELS fibers produce yarns with significantly higher tensile strength (often up to 30% higher),

- Fineness & Softness: ELS fibers can be spun into much finer yarns (up to 80s count or higher).

Sourcing Decision: For high-end shirts targeting a premium market, ELS cotton justifies the higher price… Trading companies sourcing for diverse clients should offer both tiers.

Yarn Quality (Combed vs. Carded, Spinning):

How the fibers are processed into yarn dramatically affects the final fabric.

- Combed vs. Carded:

Distinction: Combing is an extra step after carding that removes short fibers and impurities.

Quality Impact: Combed cotton yields a smoother, stronger, cleaner fabric surface with less pilling. Carded cotton is hairier and less refined.

Cost Impact: Combing adds complexity, increasing yarn cost by 15%-20%.

Sourcing Decision: For high-quality t-shirts or shirting where smooth hand-feel is paramount, specify combed cotton. For mid-to-lower tier workwear… carded cotton offers significant cost savings.

- Ring-Spun vs. Open-End Spinning:

Distinction: Ring-spinning is the traditional method… Open-end spinning is a faster, more modern process.

Quality Impact: Ring-spun yarns are generally stronger, softer, have better luster, and pill less. Open-end yarns are hairier and slightly weaker.

Cost Impact: Open-end spinning is more efficient, making the yarn 10%-15% cheaper.

Sourcing Decision: For fabrics requiring high strength and a smooth surface,ring-spun is preferred. For items where cost is the primary driver,open-end provides value.

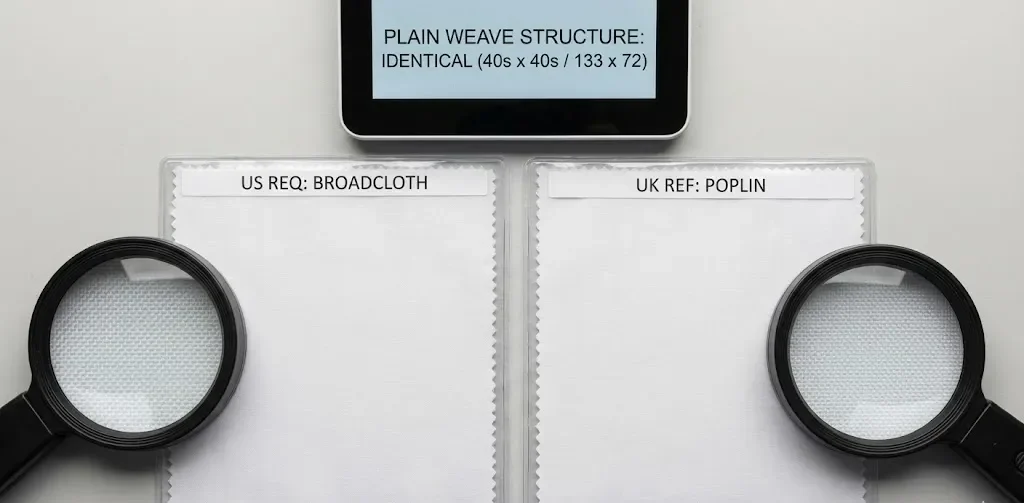

Construction Specs (Yarn Count, GSM, Weave/Knit):

These metrics define the fabric’s structure and substance.

- Yarn Count: finer counts (40s-80s) for shirts/sheets, medium counts (20s-30s) for tees/mid-weight fabrics, lower counts (<20s) for heavy canvas/denim.

- GSM (Grams per Square Meter): Examples: 180-220 GSM is ideal for quality t-shirts; 280+ GSM for sweatshirts.

- Weave/Knit: Crucial distinction! Knits (like Jersey for T-shirts)… offer stretch and comfort. Wovens (like Twill for jeans)… offer stability and structure.

Crucial Tip: Always ask suppliers for shrinkage data, especially for knit fabrics.

Finishing:

Post-weaving/knitting treatments significantly impact performance and cost.

- (Pre-Shrinking): Sourcing Focus: Verify the claimed shrinkage rate (target ≤3% for apparel, ≤5% for home textiles) and request test reports (e.g., based on AATCC TM135 / ISO 6330).

- Mercerization: Sourcing Focus: Differentiate between Single and Double Mercerized for maximum effect adds 10%-15% cost.

- Anti-Pilling Finish: Sourcing Focus: Specify the required pilling grade (e.g., Grade 4 minimum per ISO 12945-2).

- Water/Oil Repellent Finish: Sourcing Focus: Define the performance level needed (e.g., rating per AATCC 22 spray test).

- Softening Finish: Sourcing Focus: Ensure finishes comply with regulations like OEKO-TEX® STANDARD 100 for safety.

Matching Fabric Characteristics to Your End Use

This is where technical knowledge meets commercial strategy.

Apparel:

- T-Shirts: Recommendation: Combed Ring-Spun Cotton Jersey (30s-40s, 180-220 GSM) + Sanforized.

- Dress Shirts: Recommendation: Combed Cotton Poplin or Twill (60s-120s/2 ply, 110-150 GSM) + Mercerized + Easy-Care Finish.

- Workwear: Recommendation: Heavier weight Carded Cotton Twill or Canvas (10s-20s, 280+ GSM) +/- Water Repellent finish.

Home Textiles:

- Bedding: Recommendation: Hotel clients often require specific wash-cycle durability and stain-release finishes.

- Towels: Recommendation: Combed Cotton Terry Loop (16s/2 ply but very high GSM 500-800) for plushness.

Practical Tips for Evaluating Samples

Initial sample evaluation doesn’t always require a lab. Use your senses and simple tools:

- Hand-Feel: Mercerized cotton will have a distinct silky glide.

- Visual Check: Excessive surface hairiness suggests lower quality carded or open-end yarn.

Simple Tests:

- Light Transmission: Tightly woven/knitted fabrics show minimal pinpoints of light.

- Water Drop Test: If it beads up longer, it may have a finish affecting absorbency.

Wash Test Reminder: Crucially, never fully judge hand-feel or shrinkage based solely on an unwashed sample. Many mills use temporary softeners that wash out. Always request a small cutting and perform a standard home wash/dry cycle yourself to verify claimed shrinkage and true post-wash feel. Compare the results against the supplier’s provided test data.

Our Method for Assessing Cotton Samples (Before Talking Price)

Here’s the actual initial checklist our team uses when a new cotton sample hanger arrives from a potential supplier:

- Surface Cleanliness: We check for excessive lint/’hairiness’, uneven knots (neps), or visible contamination…

- Hand-Feel vs. Target Market: Does it feel right for the intended product?…

- Basic Light & Density Check: We hold it against a light panel to visually inspect weave/knit uniformity…

- Claimed Spec vs. Reality Check: If the supplier claims ‘180 GSM’, we weigh a precisely cut sample. If it’s already 10-15 GSM lighter… that’s a red flag.

Insider Tip: We perform these checks before even discussing detailed costing. If the fundamental quality isn’t there, the price becomes irrelevant.

Step 2: How to Find and Vet Cotton Fabric Suppliers

Finding reliable partners is paramount in cotton textile sourcing.

Where to Find Potential Suppliers

Diversify your search beyond the obvious:

- Online B2B Platforms (Alibaba, etc.): Useful starting point, but requires extreme caution. Sourcing Tip: Prioritize suppliers with “Verified” status, multiple years of transaction history, positive reviews, and ideally, their own factory certifications (not just a trading company profile). Never trust platform rankings alone.

- Industry Trade Shows (Intertextile, Premiere Vision, Texworld): Excellent for meeting mills directly, seeing physical samples, and assessing their capabilities firsthand.

Sourcing Tip: Check the exhibitor list online before the show, identify 3-5 target cotton mills, and schedule meetings in advance. Bring your existing fabric standards for direct comparison. - Professional Directories & Associations: Industry-specific directories can list reputable manufacturers.

- Peer Recommendations: Ask trusted contacts in the industry (but verify).

Sourcing Tip: Ask for recent (last 6 months) PO copies or contact references to confirm ongoing stable relationships, not just a casual mention. - Direct Search: Use targeted search terms like cotton fabric suppliers + [Region] (e.g., cotton fabric suppliers China, cotton jersey knit mill Portugal).

Sourcing Tip: Focus on results beyond the first page. Scrutinize the ‘About Us’ section of supplier websites for factory size (aim for >5000 sq meters for reliable capacity), equipment details, and listed certifications.

Critical Vetting Criteria

Once you have a shortlist, evaluate them rigorously:

- Technical Capability & Specialization: Do they specialize in the exact type of cotton fabric you need (e.g., fine gauge knits, heavy wovens, specific finishes)? Ask for proof of similar past productions.

- Production Capacity & Lead Times: Can their factory realistically handle your order volume within your required timeline? Ask about their current capacity utilization and typical lead times for your fabric type.

- Quality Control Systems: Do they have an established internal QC process? Do they have in-house testing capabilities (for basic tests like GSM, shrinkage) or rely solely on third parties? Request a copy of their QC manual.

- Compliance & Certifications: Do they hold internationally recognized certifications? This is crucial for market access and brand reputation.

- Communication & Responsiveness: Are they easy to communicate with? Do they respond promptly and professionally to technical questions? Poor communication during vetting often predicts problems later.

Understanding the Difference: Mill vs. Trader/Agent

Choosing who to work with depends on your needs.

Direct Mill:

Pros: Better pricing (no middleman margin), direct control over production details, potentially faster technical communication. Ideal for large, stable orders and brands with strong technical teams.

Cons: Usually higher MOQs (e.g., 1000m+ per color), less flexibility for small orders, potentially slower customer service for non-major accounts.

Trader/Agent:

Pros: Lower MOQs (can consolidate orders), access to multiple mills/fabric types, often provide additional services (QC, logistics). Ideal for smaller brands, trial orders, or sourcing diverse fabric types.

Cons: Higher price (5%-15% margin typically), less direct control over production nuances, communication can be filtered.

Sourcing Recommendation:

For stable, high-volume core fabrics, building a direct relationship with a qualified mill is often best long-term. For smaller, experimental orders or navigating complex supply chains, a reputable trader with proven mill partnerships can be invaluable. Crucially, if working with a trader, always ask for transparency regarding the actual manufacturing mill and request their certifications.

Why Certifications Aren’t Just Marketing Labels – They’re Risk Management

When we evaluate a potential new mill partner, verifying their compliance documentation is non-negotiable. For cotton fabrics, two certifications are paramount from a risk perspective:

- OEKO-TEX® STANDARD 100: This certifies that the fabric has been tested for a wide range of harmful substances and is safe for direct skin contact. This is absolutely critical for babywear, bedding, intimate apparel, or any product marketed as ‘skin-friendly.’

- GOTS (Global Organic Textile Standard): This applies if you are making an organic cotton claim. GOTS doesn’t just verify the fiber origin; it covers the entire processing chain – spinning, weaving/knitting, dyeing, finishing – ensuring environmental and social criteria are met. It requires robust traceability.

Why this matters to you as a buyer: Retailers and regulatory bodies in many markets (especially EU and USA) now demand verifiable proof for claims like organic, eco-friendly, or ‘baby-safe.’ If your supplier cannot provide valid, current certification documents for your specific production batch (not just a general factory certificate), your brand assumes the liability if challenged by customers or authorities. Verifying certifications is fundamental risk management.

Step 3: The Core Sourcing Process – From RFQ to PO

With vetted suppliers, you move to the transactional phase.

Defining Your Needs: The RFQ & Tech Pack

Your Request for Quotation (RFQ) or Technical Packet (Tech Pack) must be crystal clear. Include all specifications determined in Step 1 (Fiber, Yarn, Construction, Finish, Weight, Width, Color) plus performance requirements (shrinkage, fastness). Ambiguity here leads to incorrect quotes and samples.

Requesting and Evaluating Samples

This is a critical multi-stage approval process:

- Lab Dips (Color): Small swatches dyed to match your Pantone standards. Approve under standardized lighting (D65).

- Swatches/Hangers (Quality): Larger pieces (approx. 1 yard/meter) representing the fabric quality. Evaluate hand-feel, weight, construction against your specs.

- Pre-Production (PP) Sample (Final Standard): A sizable piece (several yards/meters) produced using bulk processes, representing the final approved quality for mass production. This PP sample becomes the binding reference standard.

Crucial: Do NOT approve bulk production until you have signed off on a PP sample that meets all your requirements.

Negotiation and Placing the Order

Key Points: Price (volume breaks), Payment Terms (e.g., 30% TT deposit, 70% against BL copy), Lead Time (confirm ex-factory date), Shipping Terms (Incoterms like FOB, EXW).

PO/Contract: Must reiterate all agreed specs, quality standards (AQL, performance tests), delivery date, and penalty clauses for defects or delays.

Step 4: Common Mistakes to Avoid in Cotton Sourcing

Based on years of troubleshooting for clients, these are the most frequent (and costly) errors:

Mistake 1: Focusing Solely on Price

Choosing the cheapest quote without rigorously comparing the underlying specifications and supplier reliability often leads to higher total costs due to poor quality, delays, or rejected goods.

Mistake 2: Vague Specifications

Sending RFQs with descriptions like good quality 100% cotton jersey guarantees inconsistent quotes and unusable samples. Precision is paramount.

Mistake 3: Insufficient Sample Approval

Approving production based only on a tiny lab dip or an initial hand feel sample is extremely risky. The bulk fabric may feel or perform differently. The PP sample stage is non-negotiable.

Mistake 4: Ignoring Lead Times & Logistics Until Too Late

Fabric production takes time (often 4-8 weeks or more). International shipping adds several more weeks. Failing to factor realistic timelines into your critical path is a common cause of missed market deadlines.

Step 5: Post-Order Essentials – Ensuring Quality Delivery

The job isn’t done when the PO is placed.

The Importance of Quality Control (QC)

Rigorous QC is your final safeguard.

- In-Line Inspection: Checking fabric during production (e.g., off the loom or knitting machine) can catch major issues early.

- Final Inspection: Thorough inspection of finished fabric rolls before shipment. Usually performed by your own QC team or a hired third-party agency.

- Standards: Inspections are typically based on agreed AQL standards like principles from ISO 2859-1. Key checks include visual defects (holes, stains, streaks), weight (GSM consistency), width accuracy, color matching (against standard), and hand-feel consistency.

- Critical performance tests:like shrinkage (e.g., AATCC TM135 / ISO 6330) and colorfastness should also be re-verified on bulk production lots.

Logistics and Documentation Overview

Ensure proper packing (especially moisture protection for cotton), timely shipping arrangements, and accurate documentation (Commercial Invoice, Packing List, Bill of Lading, Certificates of Origin if needed) for smooth customs clearance.

Conclusion: Your Path to Strategic Cotton Sourcing

Mastering this cotton sourcing guide means moving beyond simple purchasing. It requires integrating technical fabric knowledge with strategic planning, rigorous supplier vetting, precise communication, and diligent quality management.

By following these steps, you minimize risks, optimize costs, and build a reliable supply chain capable of delivering consistent quality that aligns with your brand’s promise. This systematic approach is the foundation for long-term success in the competitive apparel and textile markets.

Ready to implement a more strategic approach to your cotton sourcing?

FAQ – Common Questions from Cotton Buyers

What is the most important factor when choosing cotton fabric?

While it depends heavily on the end-use, the quality of the raw cotton fiber, primarily determined by its staple length, is the most fundamental factor influencing the fabric’s potential for softness, strength, and durability. However, yarn processing (combing) and construction (weave/knit, density) are equally critical in realizing that potential.

How do I find reliable cotton fabric suppliers?

Use a multi-channel approach: attend major industry trade shows (like Intertextile), leverage trusted industry network referrals, utilize specialized online B2B directories (vetting carefully), and conduct targeted searches for mills with specific capabilities and certifications. Always follow up with rigorous vetting.

What is a typical Minimum Order Quantity (MOQ) for cotton fabric?

MOQs vary widely. For basic, widely available fabrics dyed to a standard color, MOQs might start around 500-1000 meters. For custom colors or qualities involving special yarns or finishes, MOQs often increase to 2000-3000 meters or more per colorway due to the economics of production setup.

How can I ensure the bulk fabric matches the approved sample?

The keys are:

1: Establish the Pre-Production (PP) sample as the absolute, signed-off quality standard in your contract.

2: Implement a strict final QC inspection process comparing bulk rolls against the PP sample for color, weight, hand-feel, and visual defects using agreed-upon tolerances and AQL standards.

3: Maintain open communication with your supplier throughout production.