🧵 Introduction: The Cost of a Wrong Spec

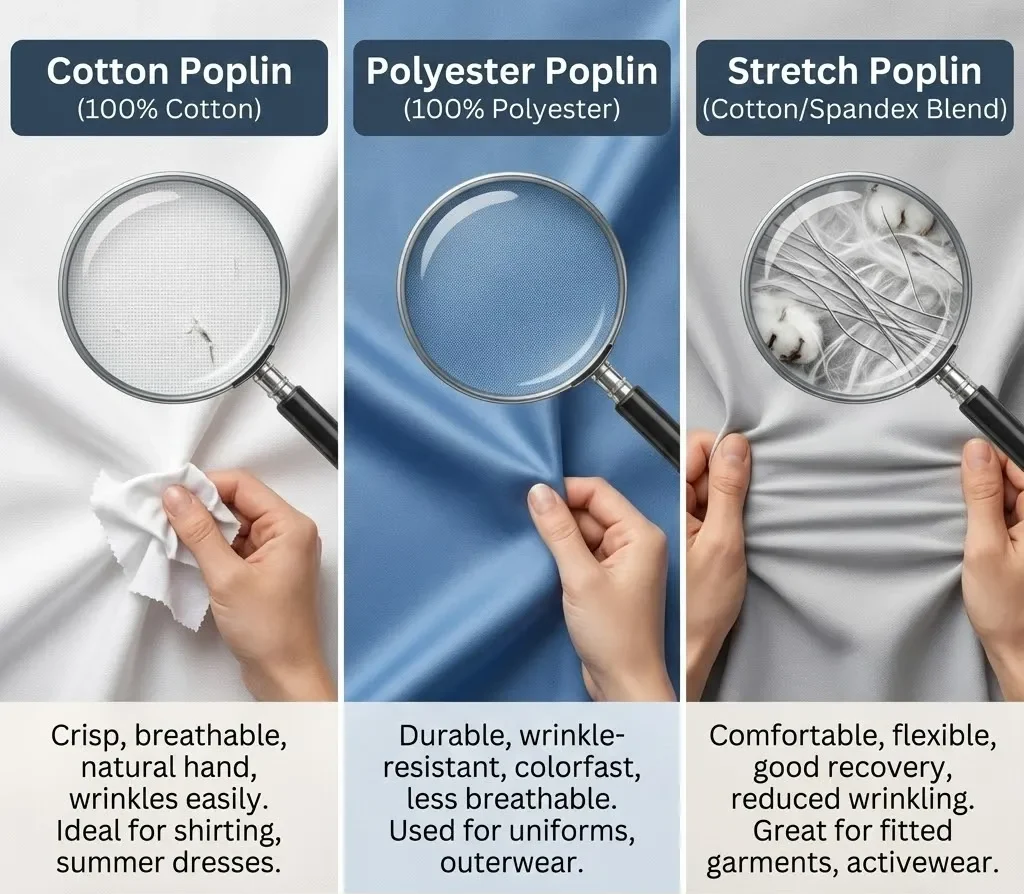

In my 20 years as a fabric manufacturer, I have seen thousands of “Poplin” orders cross my desk. The word itself is simple, but the reality behind it—cotton poplin vs polyester poplin vs stretch poplin—is a complex matrix of cost, performance, and manufacturing risk.

⚠ Real-World Failures I’ve Witnessed

- ✖The Cost Trap: Brands choosing polyester poplin for dress shirts to save $0.50/yard, only to face massive returns due to pilling and breathability complaints.

- ✖The Workwear Fail: Uniform companies specifying 100% cotton poplin without a wrinkle-free finish, resulting in shirts that look unkempt after just one hour.

- ✖The Stretch Disaster: Startups using stretch poplin without testing recovery, leading to baggy knees and elbows within weeks.

Choosing the right poplin isn’t just about feeling the swatch. It’s about understanding the shrinkage risk, cutting room distortion, sewing puckering, and lot-to-lot consistency.

📘 Your Factory-Floor Manual

This guide is designed to protect your production. We will dissect the technical DNA of the three main poplin types, provide you with “Safe Spec” matrices, and give you the exact poplin fabric PO spec template clauses you need.

🌿 What Is Cotton Poplin Fabric?

1. Definition

It is a plain-weave fabric made from 100% cotton yarns, characterized by a fine horizontal rib (created by a higher warp density), a crisp handfeel, and high breathability. It is the global standard for premium shirts and bedding.

2. Key Characteristics

- 🔹Handfeel: Cool, dry, and natural.

- 🔹Breathability: Excellent. Cotton fibers absorb moisture and allow airflow.

- 🔹Typical Use: High-end dress shirts, summer blouses, luxury bedding.

3. Factory Note: Technical Risks

- ⚠️ Shrinkage Risk: High. Requires careful shrinkage control for bulk orders.

- 🎨 Shade Control: Cotton absorbs dye naturally but can vary lot-to-lot. Poplin shade band approval is critical.

- ✨ Surface: Compatible with high-end finishes like Liquid Ammonia or Mercerization.

🔗 See our full guide on What is Mercerized Cotton?

🧪 What Is Polyester Poplin Fabric?

1. Definition

It is a plain-weave fabric made from spun polyester yarns (or continuous filament), designed to mimic the texture of cotton but with superior durability, color retention, and wrinkle resistance.

2. Key Characteristics

- 💎Easy Care: Resists wrinkles and dries instantly.

- 💎Stability: Almost zero shrinkage.

- 💎Drying Speed: Hydrophobic fibers shed water rapidly.

3. Factory Note: Technical Risks

- 🎨 Dyeing Route: Uses Disperse Dyes at high heat. Colors are vibrant and colorfastness to washing is superior to cotton.

- 🔥 Heat Sensitivity: Can glaze or melt under high-temperature ironing.

- 👔 Pressing Window: Requires precise steam settings to set pleats correctly.

🤸 What Is Stretch Poplin Fabric?

1. Definition

It is a cotton (or poly-cotton) base woven with elastane (Spandex/Lycra) filaments—usually in the weft—to provide flexibility, recovery, and a fitted silhouette.

2. What Is “Stretch”? (Spandex vs Mechanical)

- 🧬 Spandex Poplin Fabric:

Contains 2-5% elastane. Offers “snap-back” recovery. - 🔩 Mechanical Stretch Poplin:

100% Polyester woven with high-twist torque yarns to create a “spring-like” stretch without elastane. Cheaper, but less recovery.

3. Factory Note: Technical Risks

- ✂️ Distortion Control: Stretch poplin cutting distortion is a major risk if the fabric isn’t relaxed properly on the table.

- 👖 Recovery: Must be tested to prevent “bagging out” (knees/elbows).🔗 Learn about recovery testing in our Denim Guide

🎯 Which Poplin Is Best for Different End Uses?

1. Which Poplin Is Best for Dress Shirts?

For premium markets, cotton poplin is the undisputed king due to its breathability and crispness. For budget or travel shirts, blends work best.

| Feature | Cotton Poplin | Poly Poplin | Stretch Poplin |

|---|---|---|---|

| Opacity | Moderate (Depends on density) | High | High (if dense) |

| Wrinkle | Low (Needs finish) | Excellent | Good |

| Status | Luxury Standard | Budget | Modern Fit |

| Risk | Wrinkling | Pilling/Shine | Bagging |

👔 White Shirts Pro-Tip: How to make poplin less transparent? Choose high-density Cotton (e.g., 144×80) or a Poly-Cotton blend, which naturally has higher cover.

2. Which Poplin Is Best for Uniforms?

Polyester poplin (or 65/35 TC) wins on durability and color retention.

- Durability: Poly blends withstand 50+ industrial washes.

- Repeatability: Poly batches are chemically consistent; cotton varies by crop (harder to control lot-to-lot).

- Claims: Use Poly to avoid shrinkage claims in high-heat industrial dryers.

3. Which Poplin Is Best for Women’s Blouses?

Stretch poplin is preferred for fitted silhouettes to ensure comfort without sacrificing the “crisp” look.

- 👗 Stretch Poplin for Dresses: Provides the necessary “give” for bodices.

- 👗 Cotton Poplin: Best for A-line or loose summer dresses where breathability is key.

4. Which Poplin Is Best for Home Textiles?

Cotton poplin is preferred for skin contact (pillowcases/sheets).

- Pilling: Polyester poplin for sheets pilling risk is high. Cotton is safer.

- Handfeel: Cotton gets softer with washing; Poly stays the same.

- Stability: Cotton poplin for bedding shrinkage must be Sanforized to fit mattresses correctly.

⚖️ Which Poplin Is Most Stable for Mass Production?

1. What “Dimensionally Stable” Means in Production

Which poplin is most stable? Polyester Poplin.

Stability means: The fabric does not change size (shrink/grow) or shape (skew/bow) during cutting and sewing.

2. Best Choice by Scenario

- ✂️ Garment Factory:

Poly Poplin.

You can stack 100 layers high on the cutting table without “creeping” or shrinking. - 🛏️ Home Textile Factory:

Poly-Cotton (50/50).

Pure cotton sheets are a nightmare for shrinkage control in wide widths.

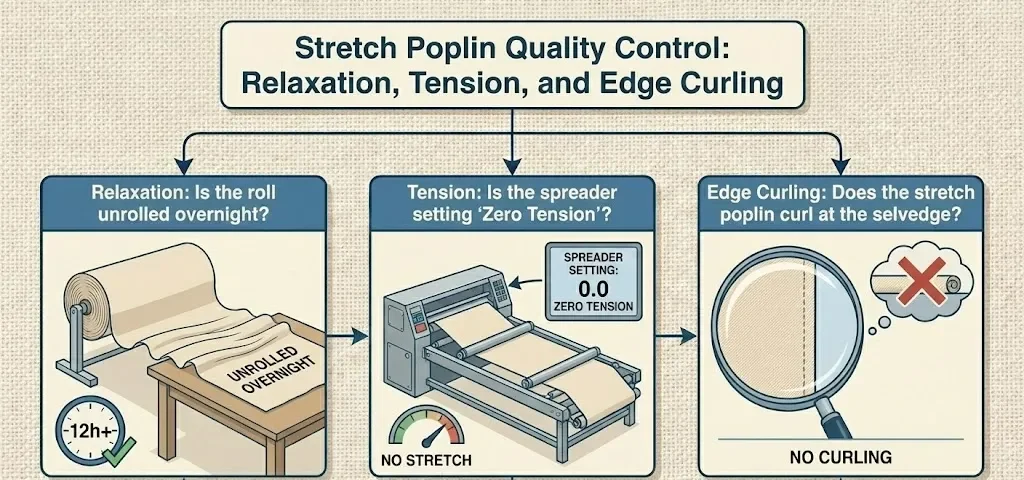

✂️ Which Poplin Is Easiest to Cut and Spread?

1. Risk Distribution by Type

Polyester poplin cutting issues include static electricity (layers sticking together) and “fusion” (knife heat melting the edge).

Stable, but fabric relaxation time before cutting poplin (24 hours) is required to release tension.

Stretch poplin cutting distortion occurs if the fabric is pulled tight during spreading. It snaps back after cutting, ruining the size.

2. Quick Floor Checks

- ❓Relaxation: Is the roll unrolled overnight?

- ❓Tension: Is the spreader setting “Zero Tension”?

- ❓Edge Curling: Does the stretch poplin curl at the selvedge?

3. Cutting Room Checklist

- Allow 24hr relaxation for Stretch & Cotton.

- Use anti-static spray for Polyester.

- Use “serrated” knives for Polyester to prevent fusing.

- Check “bowing” on all Stretch rolls before spreading.

🧵 Which Poplin Is Easier to Sew with Fewer Puckers?

1. Sewing Risk Types

Cotton is easier to sew with fewer puckers because it “grips” the thread naturally.

Poly is slippery (layers slide); Stretch fights the feed dog (tension issues).

Common in Stretch Poplin due to differential feed issues.

Common in low-density Poly Poplin.

2. Factory How-to: Reducing Puckers

- 🪡 Needle: Use sharp, fine needles (Size 70/10) for Poly to avoid punching big holes.

- 🧵 Thread: Use Core-Spun thread for Stretch to allow the seam to stretch with the fabric.

- ⚙️ Feed Dog: Lower the pressure for Stretch Poplin to fix seam waviness.

3. Sewing Line Checklist

- Cotton: Check for needle heat (unlikely) and shrinkage puckering (after wash).

- Poly: Check for seam slippage (pull test).

- Stretch: Check for “wavy seams” (differential feed adjustment needed).

🌬️ Cotton vs Polyester Poplin: Which Is More Breathable?

1. Quick Answer

Which is more breathable? Cotton Poplin is significantly more breathable.

Polyester is a plastic; it traps heat and moisture, whereas cotton allows air to circulate naturally.

2. Factory Perspective: The “Density” Nuance

- 🧵 Density Factor:

Poplin fabric breathability is affected by density. A very high-density cotton (e.g., Typewriter Cloth) can actually be less breathable than a loose-weave polyester. - ❄️ The “Cooling” Finish:

Some Poly Poplins use “Wicking” finishes to mimic cotton, but the physical airflow is still lower than natural fiber.

3. Industry Data (Lab Evidence)

According to testing standard D737 for Air Permeability:

“100% cotton fabrics consistently demonstrate 20-30% higher airflow rates compared to polyester fabrics of identical weave and weight, due to the irregular surface of natural fibers creating micro-channels.”

👔 Which Poplin Wrinkles Less—How to Reduce Creasing?

1. Quick Answer

Which poplin wrinkles less: cotton or polyester?

- ✨ Polyester Poplin: Virtually wrinkle-free.

- 🧶 Cotton Poplin: Wrinkles “the moment you look at it.”

2. Buyer Options: How to Fix It

- 🧪 Blends: Use TC Poplin (65 Poly/35 Cotton) for the best balance of comfort and flatness.

- 🛡️ Finishes: Specify Easy Care finish for poplin fabric (Resin) or Liquid Ammonia (Luxury/Soft).

- 🤸 Structure: Stretch poplin wrinkling is less visible because the elastane physically pulls the wrinkles flat.

3. Wrinkle Reduction Checklist

- Specify “Durable Press Rating” (e.g., 3.5) in PO.

- Choose Poly-Cotton blends for uniforms.

- Use “Moist Cure” finish for 100% Cotton.

4. Factory Options: Post-Wash

Poplin wrinkles after garment wash—how to reduce?

- 🏭 Factory: We use “Tunnel Finishing” (steam tunnel) for Poly garments. For Cotton, we must hand-press or use form-finishers.

- 🧺 Laundry: Polyester poplin wrinkle performance after washing is “shake out and wear.” Cotton requires ironing.

📏 Which Poplin Shrinks More? PO Shrinkage Specs

1. Quick Answer

Which poplin shrinks more: cotton vs polyester poplin?

2. Factory Spec for Cotton Orders

Recommended shrinkage tolerance for poplin shirts?

- 🌿 Cotton: -3% Warp / -3% Weft.

- 🧪 Poly: -1% Warp / -1% Weft.

- ⚠️ Stretch: -5% Warp / -5% Weft (High risk!).

3. Shrinkage Clause Template

Requirement: After 3 wash cycles at 40°C, tumble dry medium.

Tolerance: Cotton Max 3%; Poly Max 1%.

Responsibility: Supplier to replace rolls exceeding tolerance.

4. Bulk Width/Weight Tolerance

What GSM tolerance is realistic for bulk poplin?

- ⚖️GSM: +/- 5%. (e.g., Target 120gsm -> 114-126gsm is acceptable).

- 📏Width: -0 / +2cm. (Never accept narrow width).

- 🔄Variation: Poplin fabric roll to roll variation control must be within 5%.

👀 Which Is More See-Through (Opacity)?

1. Quick Answer

Which poplin is more see through: cotton or polyester?

- 💎 Polyester: Often more opaque because the yarn is smoother and reflects light (hiding the skin).

- 🌿 Cotton: Being duller, it can show shadows (skin tone) more easily.

2. How to Avoid Transparency Checklist

- Spec: Increase poplin fabric cover factor (Density). Use 133×72 instead of 110×70.

- Color: Use “Optical White” (blue-white) rather than “Natural White.”

- Yarn: Use 2-ply yarns (e.g., 80s/2) to make poplin less transparent.

- Design: Add pockets or lining.

3. Factory Check Method

We use the “Black/White Card” test.

⚠️ The Rule: Place fabric over a half-black, half-white card. If you can see the line clearly, it fails the white poplin fabric opacity test for unlined shirts.

🌈 Which Holds Color Better (Colorfastness)?

1. Quick Answer

Which poplin holds color better: cotton or polyester?

- 🏆 Polyester (Winner): Disperse dyes lock into the fiber molecule.

- 📉 Cotton (Risk): Cotton dyes (Reactive) sit on the surface and can fade with bleach or sun.

2. Tests That Prevent Production Claims

- 🧴 Crocking (Rubbing): Poplin colorfastness to rubbing dry wet spec.Critical for dark cottons (Black/Navy).

- 💦 Perspiration: Perspiration colorfastness for poplin shirts.Acid sweat can turn blue cotton red.

- 🧺 Washing: Poplin colorfastness to washing spec.

3. Test Checklist

- Cotton: Wet Crocking Grade 3.0+; Wash Fastness Grade 4.0.

- Poly: Wash Fastness Grade 4.5.

🤸 Does Stretch Poplin Bag Out? Recovery Testing

1. The “Sagging” Effect

Does stretch poplin bag out after wear?

⚠️ Yes, if the elastane quality is poor or the fabric wasn’t heat-set correctly.

This permanent deformation is technically called “Growth.”

2. How to Specify Recovery

Stretch poplin recovery spec—how to write it?

- 🧪 Test Standard: **** D3107.

- 📝 Spec Requirement: “Growth <5% after 30 mins; Recovery >90%.”

- 🏭 Factory Check: We reject rolls with recovery < 85%.

3. Quick Recovery Test Workflow

- Stretch sample to 30% elongation.

- Hold for 30 minutes.

- Release and measure immediately.

- Measure again after 1 hour.

🛑 Pass/Fail Criteria:

If it hasn’t snapped back to within 5% of original length -> FAIL.

🧶 Is Polyester Poplin Prone to Pilling?

1. Quick Answer

Is polyester poplin prone to pilling?

⚠️ Yes.

Polyester fibers are strong; when they break, they hold onto the fuzz ball (pill). Cotton fibers are weaker, so they break and fall off naturally.

2. How to Specify Anti-Pilling

Anti pilling polyester poplin spec requirements:

- 🧵 Yarn: Use “Vortex Spun” (MVS) polyester yarn (significantly less hairiness).

- 🔥 Finish: Apply “Anti-Pilling Enzyme” (for blends) or Singeing (burning off fuzz).

- 🧪 Test: Pilling test requirement (Martindale or Random Tumble) -> Grade 3.5+.

3. Anti-Pilling Checklist

- Use MVS Yarn.

- Singe (Gas) the fabric surface.

- Require Grade 3.5 minimum.

🔍 Common Defects & Fast Inspection

1. Defects by Type

Slubs, Knots, Shade Variation.

Barre (Horizontal streaks from uneven tension), Static dirt.

Skewing/Bowing, Lycra breakage (missing stretch lines).

2. Quick Checkpoints

- 🎨 Shade:

Use a shade variation poplin fabric inspection checklist. Check Center-to-Selvedge consistency. - 📏 Lines:

Check for poplin fabric barre defect causes. Hold fabric up to the light to see density streaks. - 📐 Straightness:

Perform poplin fabric skew bowing detection. Fold the fabric—do the edges align perfectly?

3. 4-Point “Snack” Checklist

(A quick check before cutting bulk)

- Check first 3 yards (start damage often occurs here).

- Check width at 3 points (start, middle, end).

- Check middle for bowing.

- Check shade against approved swatch.

💰 Cotton vs Poly vs Stretch: Price Drivers

1. What Affects Price Per Meter?

- 🧶 Fiber:

Cotton poplin vs polyester poplin cost difference. Cotton is commodity-priced (fluctuates). Poly is stable and cheaper. - 🎨 Dyeing:

Dyeing cost cotton vs polyester poplin. Cotton dyeing (Reactive) uses more water/energy = more expensive. - 🤸 Elastane:

Stretch poplin price drivers. Spandex is an expensive component, increasing the base cost.

2. Buyer Levers to Reduce Cost

Use these strategies to optimize your BOM cost:

- Switch Combed Cotton to Carded Cotton

Save 10% 📉 - Switch 100% Cotton to CVC

Save 15% 📉 - Switch Piece Dye to Rotary Print (for patterns)

Optimize Cost 📉

📋 “Safe Specs” for Each Type (Factory Decision Matrix)

1. Safe Spec for Cotton Poplin

- 👔 Shirt (Classic):

40s x 40s / 133 x 72 / 120 GSM. - 👚 Blouse (Refined):

60s x 60s / 90 x 88 / 105 GSM.

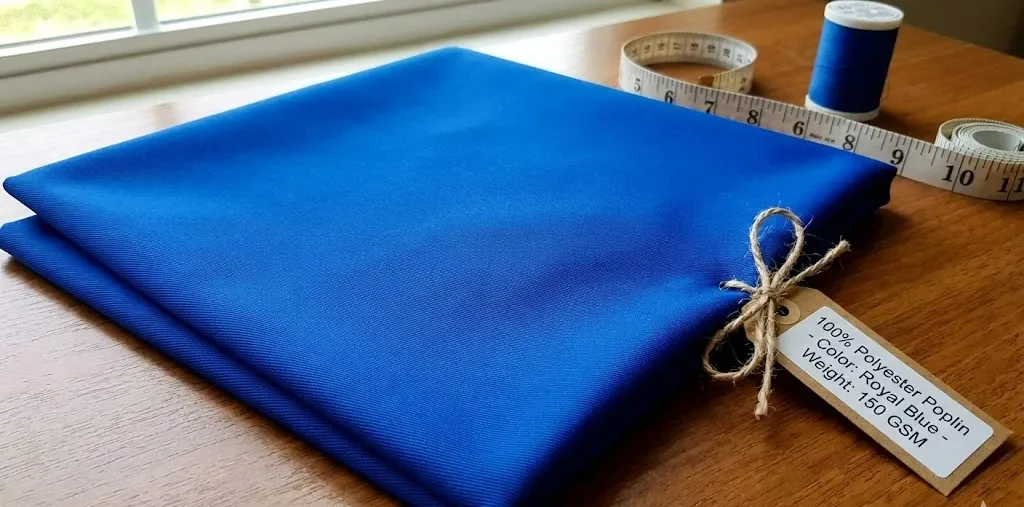

2. Safe Spec for Polyester Poplin

- 👮 Uniform (Durable):

45s x 45s (Poly/Cotton) / 110 x 76 / 115 GSM. - 🏥 Scrub (Opaque):

75D x 150D / 150 GSM.

3. Safe Spec for Stretch Poplin

- 🧘 Fitted Shirt (Balanced):

50s x 40s+40D / 120 GSM / 3% Spandex.

📚 Example Library

- 45×45 133×72: The global “Standard Poplin.”

- 50s x 50s: High-end crisp poplin.

📋 Copy-Paste PO Spec Templates

1. Cotton Poplin PO Template

Yarn: 40s x 40s

Density: 133 x 72

GSM: 120 ± 5%

Shrinkage: Max 3% (AATCC 135)

Finish: Mercerized + Sanforized

Colorfastness: Wet Crock 3.0; Wash 4.0

Inspection: 4-Point System (Max 20 pts/100yds)

2. Polyester Poplin PO Template

Yarn: 45s x 45s

GSM: 115 ± 5%

Shrinkage: Max 1%

Pilling: Grade 3.5 (ASTM D3512)

Heat Set: Yes (190°C)

Colorfastness: Wash 4.5

3. Stretch Poplin PO Template

Recovery: Growth <5%; Recovery >90% (**** D3107)

Shrinkage: Max 5% (Pre-shrunk required)

Skewing: Max 3%

Packaging: Loose roll (prevent relaxation shrinkage)

✅ Single Page PO Checklist

- Fabric Construction (Yarn/Density).

- GSM & Width Tolerance.

- Shrinkage Spec (Method + Limit).

- Colorfastness (Crock/Wash).

- Pilling Grade (for Poly).

- Recovery Spec (for Stretch).

- Shade Band Requirement.

🎯 Conclusion: Making the Right Choice

For Breathability, Luxury, and Skin Health.

For Uniforms, Color Durability, and Cost.

For Fitted Fashion and Comfort.

💡 Expert Advice

As a 20-year fabric manufacturer, my advice is simple: Don’t just buy “Poplin.” Buy the spec that solves your customer’s biggest complaint.

- ✔If they hate ironing -> Buy Poly.

- ✔If they hate sweating -> Buy Cotton.

❓ FAQ: Quick Answers for Poplin Sourcing

1. Is polyester poplin hot to wear?

Yes, generally speaking. Is polyester poplin breathable for shirts? Not really. Because polyester is a synthetic, hydrophobic fiber, it traps body heat and moisture rather than absorbing it like cotton.

⚠️ Note: While “wicking” finishes can help move sweat away, a 100% polyester poplin shirt will always feel more humid in hot climates compared to cotton poplin.

2. Can I use sublimation printing on 100% cotton poplin?

No. Dye sublimation requires synthetic fibers (polyester) to bond with the ink under heat. If you try to sublimate on 100% cotton poplin, the image will wash out immediately.

- For Cotton: Use Digital Direct-to-Garment (DTG), Screen Printing, or Reactive Printing.

- For Sublimation: Use polyester poplin or a blend with at least 65% poly.

3. Does stretch poplin “bag out” (lose shape) after wearing?

Does stretch poplin bag out after wear? It can, if the recovery is poor. “Bagging” happens when the elastane fibers stretch but fail to snap back completely.

🛡️ Prevention: Buyers must specify a Growth <5% and Recovery >90% standard (tested via ASTM D3107) in their purchase order.

4. Which is more expensive: Cotton or Polyester Poplin?

Cotton poplin vs polyester poplin cost difference: Generally, cotton poplin is 30-50% more expensive than polyester poplin due to raw material costs and the more complex dyeing process (reactive dyes requires more water and energy).

Stretch poplin is usually the most expensive option because Spandex/Elastane is a premium raw material.

5. How do I stop white poplin shirts from being see-through?

White poplin fabric opacity how to choose: Don’t just increase the weight (GSM); increase the density (Cover Factor).

- ✔A standard 110×70 poplin may be sheer, but a 133×72 or 144×80 construction will be opaque.

- ✔Using 2-ply yarns (e.g., 80s/2) also improves coverage significantly compared to single yarns.