🧬 Introduction: Why All Cotton Is Not Created Equal

As a textile supplier, I often tell my clients: the final quality of a fabric is 70% decided at the yarn stage, and the quality of that yarn is 100% dictated by the physical properties of its raw material—the cotton fiber.

Have you ever wondered why two “100% Cotton” t-shirts can feel so different? Why one pills after a single wash, while the other remains silky smooth for years?

This guide will take you deep into our QC lab. We’ll pull back the curtain on the three core cotton quality tests that professional mills and buyers must review before purchasing raw cotton: Fiber Length, Micronaire, and Fiber Strength. Using data, industry standards, and real-world factory experience, we will show you how these numbers on a report directly impact the final garments you produce.

(This guide assumes a basic understanding of cotton. For a foundational overview of the fiber itself, we recommend first reading: Pure Cotton Beginner’s Guide.)

📈 The HVI Test: How We Measure Cotton Quality

Before we dive into the core tests, we must first answer: what is HVI testing in cotton?

In our factory, evaluating the quality of raw cotton is not a guessing game. We rely on the HVI (High Volume Instrument). This is a sophisticated, high-speed set of automated instruments that can objectively test a bale of cotton for all its key physical properties in minutes.

An hvi cotton test report sample is the fiber’s “report card.”

For a B2B buyer, you don’t need to know how the machine works, but you must know how to read its report. We’ll now focus on the three most important metrics on that report: Staple Length, Micronaire, and Fiber Strength.

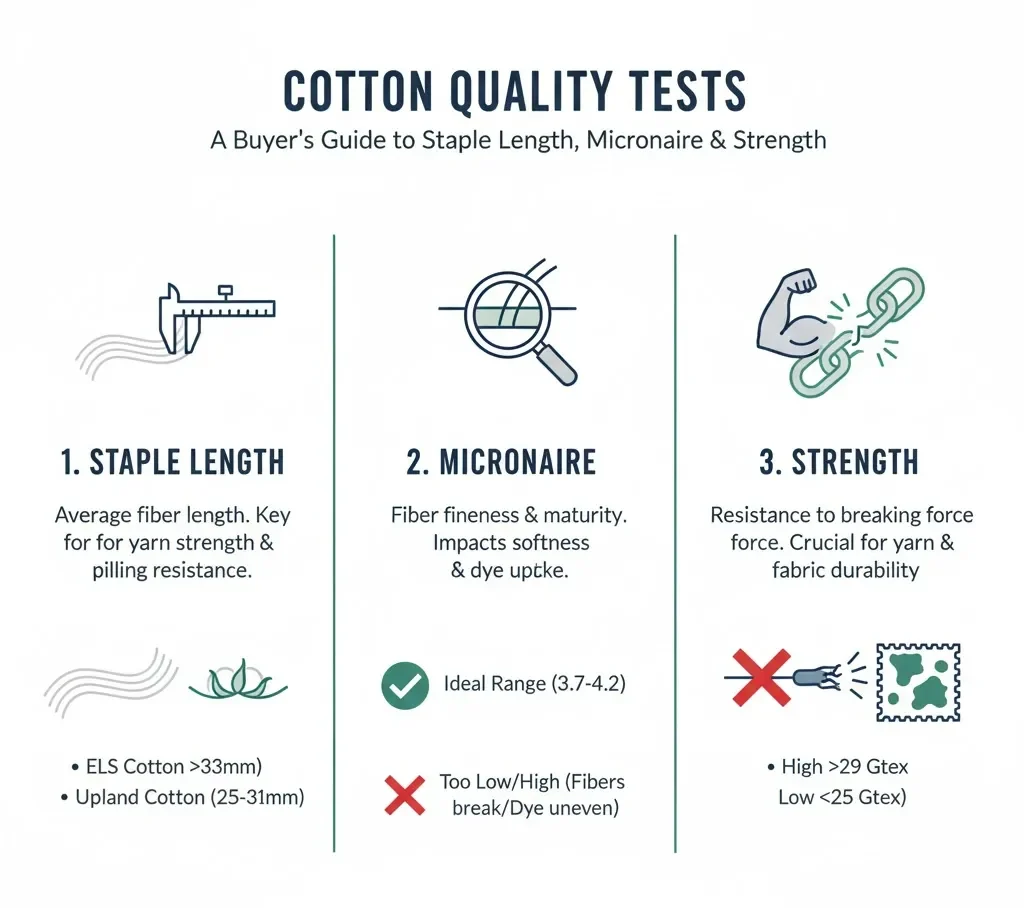

🔬 Foundational Tests: Defining the 3 Core Quality Metrics

Test 1:Fiber Length – Standards for measuring quality

In simple terms,Fiber Length It’s the average length of the individual cotton fibers. This is, without question, the most important factor in determining the cotton’s grade, quality potential, and price.

Why it Matters (The B2B Impact)

This is where the data connects to the product. In our spinning mill, longer fibers (like pima cotton staple length mm) mean the yarn can be twisted more times, with fewer fiber ends exposed. This is the simple physical reason why long staple cotton fabric is softer, smoother, and vastly more resistant to pilling (cotton staple length and pilling are directly correlated). This fiber characteristics of cotton is paramount.

How to Read the Specs: A Buyer’s Staple Length Chart

- Short Staple (8-16mm): Used for carded, open-end yarns. Suitable for low-cost denim, canvas, and flannel.

- Medium Staple (16-25mm): The standard for upland vs long staple cotton difference. This is regular cotton, the versatile workhorse for most mid-range fabrics.

- Long Staple (25-33mm): Premium cotton, typically required for fine, combed ring spun yarn.

- Extra-Long Staple (ELS) (>33mm): The luxury tier, reserved for brands like Pima and Egyptian. This is the required spec for els cotton for premium bedding.

(We have a deep-dive comparison of the two most famous ELS cottons here: Pima cotton VS Egyptian cotton

Test 2: Micronaire – The Key to Dyeing and Feel

This is the “insider” metric that 99% of consumer blogs miss, but it’s one of the most critical cotton quality parameters for sourcing.

It is a complex unit that measures two things at once: fiber fineness (thickness) and maturity (the thickness of the fiber’s cell wall).

The key takeaway is that Micronaire is NOT a higher is better metric. It’s a sweet spot metric. You want it just right.

Why it Matters (The B2B Impact)

This is the metric our dyehouse manager fears the most. The impact of micronaire value cotton dyeing is dramatic and often irreversible.

(Factory Experience – Dyeing Disaster)

- Low Micronaire (e.g., < 3.4): These are immature fibers. Their cell walls are thin and collapse into flat ribbons. In the dye bath, they act like a sponge, absorbing too much dye, which leads to a “streaky” appearance, dark patches, and a high risk of neps (small knots of tangled, over-dyed fibers).

- High Micronaire (e.g., > 5.0): These are over-mature or coarse fibers. They are too thick and round, and the dye has trouble penetrating to the core. This results in a “frosty” or light-colored appearance, poor dye yield (wasting dye), and a stiff, rough hand-feel.

How to Read the Specs: The Micronaire Sweet Spot

- Premium Range (The Sweet Spot): 3.7 – 4.2 (This is the ideal range for perfect dye uniformity and a soft hand-feel).

- Acceptable Range: 3.5 – 4.9

- Discounted (High Risk Range): < 3.4 (High risk of streaky dyeing) or > 5.0 (Poor dye yield, rough feel).

Test 3: Fiber Strength (g/tex) – Key metrics for measuring durability

Cotton fiber strength g tex explained: The unit is “grams per tex.” A tex is a unit of fiber fineness, so g/tex measures the force (in grams) required to break a fiber bundle of a specific size (one tex). In simple terms: it’s the fiber’s tensile strength. This number directly dictates the durability of your final garment.

Why it Matters (The B2B Impact)

While cotton staple length vs yarn strength are related, strength is its own independent metric. As confirmed by analyses from Textile World, a higher cotton fiber strength (e.g., 30 g tex cotton strength benchmark or higher) allows spinning machines to run at faster speeds with fewer ends down (yarn breakages). This directly reduces spinning costs and improves knitting efficiency. For the final garment, it means superior abrasion resistance and tear strength.

Factory Data:Our internal cotton hvi vs afis difference (HVI vs. advanced fiber information) discussions always revolve around this. While HVI gives the bulk strength, AFIS can tell us the ‘weak fiber’ percentage. We adhere to strict HVI testing protocols based on ASTM D5867 to ensure all raw cotton we accept is traceable and meets our high-strength benchmarks.

How to Read the Specs: A Buyer’s Strength Chart

- 24-27 g/tex: Medium Strength (Standard Upland cotton)

- 28-30 g/tex: Strong (High-quality Upland cotton, good for denim warp yarn requirements)

- 31-35+ g/tex: Very Strong (Pima/Supima ELS cotton grade)

📊 From Data to Decision: How to Use HVI Specs in Your Sourcing

Knowing what Staple, Micronaire, and Strength mean is good. Knowing how to use them to engineer your product is what makes you an expert buyer.

How These 3 Factors Work Together

Internal Case Study

Let’s look at a real case. A client wanted to develop a soft yet durable premium t-shirt, a common request for pima cotton t shirts. Here’s our engineering breakdown:

- Goal: Soft → This requires a smooth yarn. Our solution: specify a high Staple Length (e.g., 35mm+ Pima) to allow for fine, smooth spinning.

- Goal: Durable → This requires high tensile strength. Our solution: specify a high Fiber Strength (e.g., > 32 g/tex) to ensure the fabric resists pilling and tearing.

- Goal: Vibrant, Even Color → This requires perfect dyeing. Our solution: strictly control the Micronaire (e.g., 3.8-4.1) to prevent streaks and ensure deep color saturation.

Conclusion: All three metrics had to be specified. High staple length alone was not enough. This holistic specification is the key to engineering a successful fabric.

These three fiber metrics directly determine the quality of the yarn. To understand the next step—how yarn is made—please read our guides on Ringspun vs Open-End vs Compact and The difference between carded cotton and combed cotton)

How to Choose the Right Cotton Quality for Your Product Line

Here are three common scenarios I discuss with brands.

Scenario 1: Sourcing for High-End T-Shirts & Bedding

Strategy: Your goal is hand-feel and durability. pima-cotton-vs-egyptian-cotton and other ELS cottons are mandatory.

Spec Suggestion: Staple Length > 33mm, Strength > 30 g/tex, and a Micronaire locked in the premium “sweet spot” (3.7-4.2).

Scenario 2: Sourcing for Heavyweight Hoodies & Denim

Strategy: Your goal is durability and structure. You need a fabric that can take abuse.

Spec Suggestion: Strength (> 28 g/tex) is your first priority. Staple Length can be Medium/Long (which lowers cost), but Micronaire must be in the acceptable range (3.5-4.9) to ensure your dark indigo or black dyes come out even.

Scenario 3: Sourcing for Promotional/Mass-Market Items

Strategy: Your goal is cost control.

Spec Suggestion: Use standard Medium Staple cotton. Your job here is not to maximize specs but to prevent minimums. Set a floor: Micronaire MUST be > 3.5 (to avoid dye disasters) and Strength MUST be > 24 g/tex (to avoid the fabric falling apart).

How to Write Quality Specs into Your Purchase Order (PO)

This is how you turn this knowledge into an executable, legally binding instruction.

(E-E-A-T Signal: Real-World Example)

A new client once complained their t-shirts were pilling badly. We checked their PO to the old supplier, and it just said: “30S Combed Cotton, 180 GSM.” The problem? They never set a raw material spec. A mill can use very cheap, low-strength, low-length fibers, comb them, and still technically meet that PO. The brand specified the process (Combed) but not the raw material quality (HVI specs).

The Difference Between a Bad PO and a Professional PO

Bad PO: 100% Combed Cotton, 30/1, 180 GSM

Professional PO (Your Template): 100% Combed Cotton, 30/1, 180 GSM. Raw cotton must meet the following HVI specs: Staple Length ≥ 30mm, Strength ≥ 29 g/tex, Micronaire 3.7-4.2, Uniformity Index > 83%.

(E-E-A-T Signal: Sourcing Tip)Buyer Tip: Always add “HVI test method per ASTM D5867” and “Test reports from bale samples and bulk lot required for approval.” This single clause, a core part of any cotton fiber qa checklist for mills, shifts quality from a “hope” to a “requirement” and protects you from suppliers substituting inferior raw materials.

(This clause is your single best tool for risk mitigation. To learn how this fits into the complete procurement process, read our strategic-cotton-sourcing-guide.)

🏁 Conclusion: Quality is Not a Guess, It’s a Specification

High-quality cotton fabric is not a vague concept. It is a series of measurable, verifiable HVI data points that are decided before spinning even begins. As your technical partner, we believe in this data-driven approach. We insist on starting with the best raw material—verified by HVI cotton testing—to provide you with a fabric that is truly superior.

(We are ready to provide this level of transparency for your next project. contact us to request the HVI technical specifications for the fabrics in our cotton fabrics.)

❓ FAQ (Frequently Asked Questions)

What is HVI testing in cotton?

HVI (High Volume Instrument) is a set of high-speed, automated machines that objectively measure the key physical properties of raw cotton, including cotton fiber length, cotton fiber strength, Micronaire, uniformity, and color. It’s the global standard for grading and pricing cotton.

How do I read a cotton HVI report?

To read an HVI cotton report, focus on the three key metrics: Staple (Length, higher is better), Mic (Micronaire, aim for the 3.7-4.2 “sweet spot”), and Str (Strength in g/tex, higher is better). Also, look at the UI (Uniformity Index, higher is better).

Why is Micronaire so important for dyeing?

Micronaire indicates fiber maturity. Low micronaire (immature) fibers absorb too much dye, causing streaky dyeing and dark patches. High micronaire (coarse) fibers resist dye, causing a light or “frosty” appearance. A consistent Micronaire is essential for uniform color.

How does fiber length relate to yarn count?

They are directly related. Only long, fine fibers (High Staple Length) can be successfully spun into very fine yarns (High Yarn Count, like 80s or 100s). You cannot make a fine 100s yarn from short-staple cotton.

For more on this, see our fabric-weight-guide-yarn-count-gsm.

Is Pima cotton always better than Upland cotton?

From a technical fiber property standpoint (length, strength), yes. But “better” depends on the product. For a luxury t-shirt where softness is key, Pima is better. For a cost-effective, durable work-pant, a high-strength Upland cotton might be the smarter choice.