👖 Introduction: The Critical Metrics of Denim

In the world of denim production, two numbers on a spec sheet hold more power than any other: Weight (oz) and Shrinkage (%).

Denim weight is the fabric’s thickness measured in ounces per square yard, while shrinkage is the percentage size change after washing and drying. Together, they decide how heavy your jeans feel, how they drape, and most critically, whether the final fit matches your tech pack after the wash process.

⚠️ Why Precision Matters

For designers, pattern makers, and sourcing managers, getting these numbers wrong is not an option. A miscalculation in weight results in a garment that feels like armor or tissue paper. A miscalculation in shrinkage results in thousands of pairs of jeans that are either too tight or too short.

This guide is written from the factory floor. We will move beyond simple definitions to give you the practical formulas, conversion charts, and production insights you need to master denim weights and shrinkage control.

🏭 Why Do Denim Weight and Shrinkage Matter in Production?

Denim weight and shrinkage matter because they control how a garment feels on the body, how it behaves in sewing and washing, and whether bulk production matches the approved fit samples.

From a production perspective, these are the “guardrails” of your product.

📏 1. Fit Integrity

If you cut a pattern for a rigid 14oz denim but switch to a 10oz stretch denim without adjusting, the fit will be completely loose and unstructured.

⚙️ 2. Production Efficiency

Heavyweight denim requires different machinery settings (slower speeds, thicker needles) than lightweight shirtings.

💰 3. Cost Control

Heavier denim uses more cotton yarn, directly increasing the cost per yard.

⚖️ What Does “Denim Weight in Oz” Actually Mean?

Denim weight in oz (ounces per square yard) tells you how heavy and dense a denim fabric is, and is usually converted from GSM using ASTM D3776 testing.

While most of the world uses the metric system, the heritage of denim keeps it firmly rooted in the imperial system: Ounces per Square Yard (oz/yd²).

1. The Definition

If you cut a piece of denim exactly one yard wide by one yard long and weighed it, that number is its “weight.”

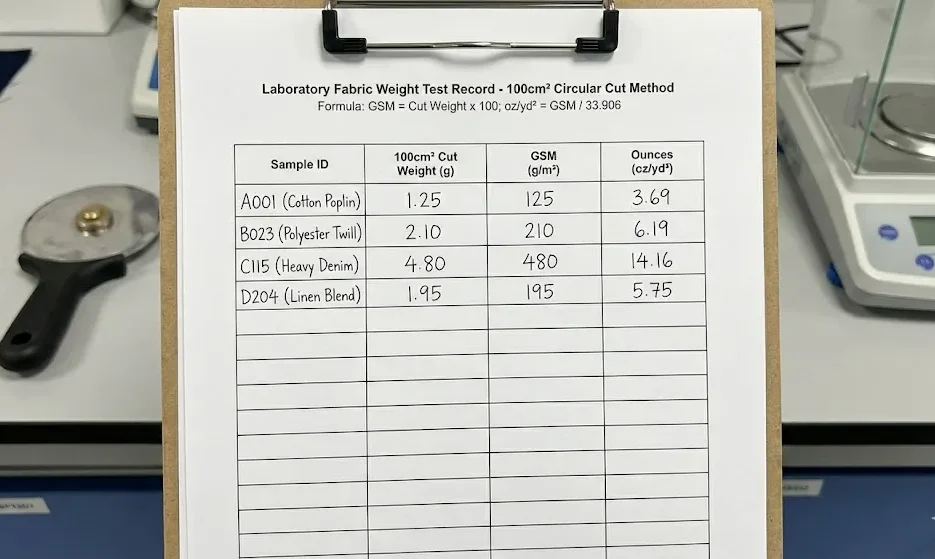

2. The Factory Process

In our lab, we don’t cut huge squares. We use a precise circular cutter to take a 100cm² sample, weigh it in grams to get the GSM (Grams per Square Meter), and then use a conversion formula to get the ounces.

3. The Standard

We follow ASTM D3776 standards to ensure accuracy.

📊 Denim Weight Chart: Oz and GSM Conversion

Most denim fabrics for jeans range from about 8 oz (around 270 GSM) to 16 oz (around 540 GSM), with shirts, jeans, and jackets each using different weight bands.

Confusion often arises when converting between metric and imperial. Here is a quick reference chart for denim fabric weight chart conversions:

| Weight Class | Ounces (oz/yd²) | GSM (g/m²) | Common Use |

|---|---|---|---|

| Lightweight | 4 oz | ~135 GSM | Shirts, Linings |

| 6 oz | ~200 GSM | 6oz to grammes reference | |

| 8 oz | ~270 GSM | Summer Dresses, Kids | |

| Mid-weight | 10 oz | ~340 GSM | Skinny Jeans, Summer Jeans |

| 12 oz | ~400 GSM | 12 oz denim jeans (Standard) | |

| 14 oz | ~475 GSM | 14 oz denim (Classic Rigid) | |

| Heavyweight | 15 oz | ~510 GSM | 15 oz denim fabric (Premium) |

| 20 oz+ | ~680+ GSM | Hardcore Raw Denim |

Note: To calculate yourself, use this formula: gsm to ounces = GSM / 33.906. For example, 220 gsm to oz is approx. 6.5 oz.

⚖️ What Are the 3 Main Denim Weight Classes?

Denim is usually grouped into three weight classes: lightweight (4–10.5 oz), mid-weight (11–15.5 oz), and heavyweight (16 oz and above).

🪶 1. What is Lightweight Denim Used For?

Lightweight denim (4–8 oz) is used for shirts, summer dresses, and soft womenswear where drape and comfort matter more than abrasion resistance.

- Common Products: light weight denim shirt, light weight denim jacket for women, chambray-style dresses.

🏭 Factory Note:

This fabric is prone to puckering during sewing. We lower the thread tension and use finer needles to prevent damaging the lighter weave. It is ideal for summer weight denim collections.

👖 2. What is Mid-Weight Denim Used For?

Mid-weight denim (11–14 oz) is the most common choice for all-season jeans, balancing comfort, durability, and sewing efficiency.

- Common Products: The vast majority of classic 5-pocket jeans (denim medium wash or dark), standard comfort denim with stretch.

🏭 Factory Note:

This is the “sweet spot” for production. Our machinery runs at optimal speeds with 12-14oz fabric, making it the most cost-effective tier to produce.

🛡️ 3. What is Heavyweight Denim Used For?

Heavyweight denim (15 oz and above) is mainly used for heritage raw jeans and workwear where stiffness and long-term wear are key selling points.

- Common Products: heavy weight denim jeans, heavy denim jeans mens, durable work jackets.

🏭 Factory Experience:

In our factory, we treat 16oz+ denim differently. We reduce sewing speed by about 30% and use thicker, specialized titanium-coated needles when running heavyweight denim to avoid needle breakage and skipped stitches.

The thicker fabric requires more force to penetrate, and high speeds can cause friction heat that melts synthetic threads.

⚖️ What Is the Difference Between Greige Weight and Finished Weight?

Greige weight is the fabric weight before washing and finishing, while finished weight is measured after processes like sanforizing and washing, which usually increase the fabric’s density.

This is a critical distinction for sourcing.

1. The Scenario

You order a “12oz” denim. Is that the weight on the roll (Greige/Raw) or the weight of the jeans after they are washed (Finished)?

2. The Reality

When denim is washed, it shrinks. As it shrinks, the yarns pack closer together, increasing the density. A fabric that starts as 12oz Greige can easily become 13oz or 13.5oz Finished after a heavy stone wash and pre-shrinking.

3. The Lesson

Always clarify with your supplier: “Is this 12oz before or after wash?” This ensures you don’t end up with a garment that is heavier and stiffer than you designed.

📉 What Is Shrinkage in Denim?

Shrinkage in denim is the percentage size reduction that happens when the fabric or garment is washed and dried, mainly due to cotton fibers relaxing and the weaving tension being released.

Cotton fibers swell when wet. In the weaving process, yarns are pulled under high tension. When that tension is released by water and heat, the fabric “snaps back” to its natural, relaxed state.

⚠️ Key Variables

- Direction: Denim shrinks in both directions, but mostly in the Warp (length/vertical) direction, often up to twice as much as the Weft (width/horizontal).

- Composition: Generally, the higher the cotton content and the looser the weave, the more potential for shrinkage.

(To understand how we control this in the factory, read about the Sanforizing process in our guide: how-raw-denim-becomes-washed-denim-process)

📉 How Much Does Denim Shrink on Average?

- Sanforized Denim: Most shrinks less than 3%.

- Unsanforized (“Shrink-to-Fit”) Denim: Can shrink by about 7–10% after the first few washes.

This variance is massive and dictates your entire pattern-making strategy.

🔄 Sanforized vs. Unsanforized Denim: What’s the Difference?

Sanforized denim is pre-shrunk on a sanforizing machine so shrinkage stays under about 3%, while unsanforized denim is not pre-shrunk and is designed to shrink significantly on the body.

✅ Sanforized (The Standard)

99% of jeans sold today. The fabric is steamed, stretched, and compressed on a rubber belt machine before cutting. This stabilizes the size.

🚿 Unsanforized (Raw/Loomstate)

Targeted at the “Denimhead” niche. The jeans are sold “oversized” and the customer must soak them in a bathtub to shrink them down to fit. This is the shrink-to-fit experience.

🧬 How Does Stretch Denim Shrink Differently?

Stretch denim can shrink in both the cotton and elastane components, and may also grow again with wear or high-heat drying.

Stretch denim introduces a new variable: Elastane (Spandex/Lycra).

1. The “Bagging” Risk

While cotton shrinks, elastane stretches. If not properly heat-set, stretch jeans can “grow” or bag out at the knees after a few hours of wear.

2. The Heat Risk

High heat in a dryer can cause elastane to snap back violently or degrade, leading to unpredictable shrinkage.

3. Factory Protocol

For stretch denim, we conduct rigorous “Relaxation Shrinkage” tests (steaming without pressure) and “Growth/Recovery” tests to ensure the jeans hold their shape.

🧮 How Do You Calculate Denim Shrinkage for Your Tech Pack?

Shrinkage (%) is calculated as (before-wash length − after-wash length) ÷ before-wash length × 100%.

As a pattern maker, you cannot guess. You must calculate.

The Formula

- Mark a 50cm x 50cm square on the unwashed fabric.

- Wash and dry the fabric according to your final garment wash recipe.

- Measure the square again. Let’s say it is now 48cm long.

Calculation: (50 – 48) / 50 = 0.04 = 4% Shrinkage.

The Adjustment

You must then add 4% to the length of your paper pattern so the final garment comes out to the correct size.

⚠️ Critical Note

Different rolls from the same mill can vary by 1-2%. We recommend testing every batch.

🌪️ What Is Leg Twist (Skewing) in Denim?

Leg twist, or skewing, is the twisting of a denim leg seam after washing, caused by unbalanced shrinkage along the fabric’s twill direction.

⚠️ The Phenomenon

- Visual: You’ve likely seen jeans where the side seam wraps around to the front of the shin. This is leg twist.

- Cause: Regular twill weave (Right Hand Twill) has a natural diagonal tension. When it shrinks, it pulls in that diagonal direction.

✅ Prevention

“Skewing” the fabric during the Sanforizing process can counteract this.

(This is a major defect. Learn more in our denim-fabric-defects-guide.)

👗 What Denim Weight and Shrinkage Strategy Should You Use for Different Garments?

Different denim garments need different weight and shrinkage targets: shirts and dresses use lightweight, low-shrinkage fabrics, while raw heritage jeans can tolerate higher shrinkage if patterns are adjusted correctly.

1. What Weight Denim is Best for Shirts and Dresses?

Denim shirts and dresses usually work best with 4–8 oz denim, with shrinkage kept under about 3% to avoid tight shoulders and armholes.

- Target: light weight denim fabric by the yard sourcing should focus on soft, fluid fabrics.

- Shrinkage: Must be minimal (<3%). A shirt collar that shrinks 5% becomes unwearable (choking hazard).

2. What Weight Denim is Best for Skinny Jeans?

Skinny jeans typically use 10–12 oz stretch denim with controlled shrinkage under 3% and carefully tested recovery to maintain shape.

- Target: Mid-weight comfort denim with high recovery.

- Shrinkage: Precision is key. A skinny jean has negative ease; any unexpected shrinkage makes it impossible to put on.

3. What Weight Denim is Best for Heritage Raw Jeans?

Heritage raw jeans often use 14–16 oz unsanforized denim with 7–10% shrinkage, and patterns must be graded up to allow for shrink-to-fit.

- Target: Heavyweight, rigid fabric.

- Shrinkage: The shrinkage is a feature, not a bug. The pattern must be cut 1-2 sizes larger than the tag size.

🤝 Conclusion: From Buyer to Strategic Partner

Denim weight and shrinkage are not just numbers; they are the engineering constraints of your product. Mastering them allows you to predict costs, control quality, and deliver a fit that customers trust.

We are more than just a supplier; we are your technical partner.

- (To source the right denim with the right specs, visit our denim-fabric-sourcing-guide.)

- (Contact us at contact-us to request our latest fabric charts and shrinkage reports.)

❓ FAQ: Quick Answers about Denim Weight and Shrinkage

Is 15 oz denim heavy?

15 oz denim is considered the start of “heavyweight” for standard jeans. It feels noticeably stiffer and thicker than the common 12 oz denim found in most malls. It is the gold standard for durable, heritage, and workwear styles that require a “break-in” period.

Does 100% cotton denim shrink more than stretch denim?

Generally, yes. 100% cotton denim usually shows more visible shrinkage in both length and width because it lacks the stabilizing effect of synthetic fibers. However, stretch denim has its own risk: elastane can “snap back” or degrade under high heat, causing unpredictable size changes. Both require testing.

How much extra length should I add for shrinkage?

It depends entirely on the fabric’s test results. For standard sanforized denim (under 3% shrinkage), adding 1–2 cm to the inseam and sleeve length is often sufficient safety margin. For unsanforized denim, you may need to add 5–8 cm or more, based on rigorous wash testing.

Does heavier denim shrink more than lightweight denim?

Not necessarily. Heavier denim does not always shrink more in percentage terms, but its shrinkage feels more dramatic because the fabric is stiffer and thicker. A 5% shrink in a stiff 16oz jean makes it feel much tighter than a 5% shrink in a soft 10oz shirt.

What is the best denim weight for all-season jeans?

For versatile, all-season jeans, 11–13 oz denim is the undisputed champion. It balances durability with comfort, isn’t too hot for summer or too thin for winter, and offers the best production efficiency for factories. This is the denim weight of choice for most major brands.