Introduction: Understanding Fabric Machine Weaving Type

When you look closely at a piece of fabric, have you ever noticed the intricate pattern of threads crossing over and under each other? That pattern is the fabric weave type, and it’s the fundamental architectural blueprint of any woven textile. While fibers like cotton or polyester provide the raw material, it’s the way those threads are interlaced on a loom that dictates much of the fabric’s final character – its texture, drape, durability, luster, and even breathability.

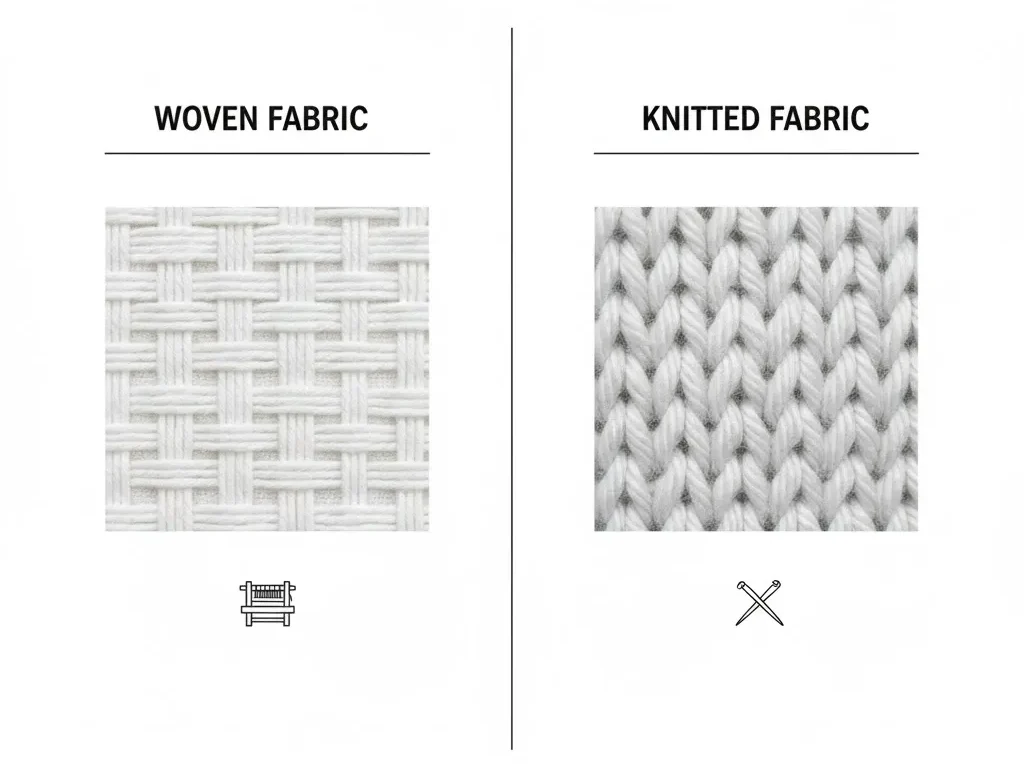

Many people confuse woven fabrics with knitted fabrics. Knits, like your favorite t-shirt, are made from interlocking loops of yarn, giving them inherent stretch. Wovens, like a crisp dress shirt or sturdy denim, are created by interlacing two sets of threads at right angles: the warp (running lengthwise) and the weft (running crosswise). Understanding the different ways these warp and weft threads can interlace – the fabric weaving types – is essential knowledge for anyone involved in apparel or textile sourcing.

Industry Perspective:

During my interactions with international clients at our textile factory, a frequent question arises: “Why is twill weave better for trousers, while plain weave dominates shirting?” It’s a question that goes to the heart of fabric engineering. According to data published in the ‘Textile Institute Global Fabric Performance Review,’ over 62% of the application differences among woven apparel fabrics are directly determined by their weave structure.

We see this daily. Our internal tests comparing twill and plain weave fabrics made from the same yarn and density show twill consistently offers about 14.6% higher warp tensile strength. This isn’t just theory; it’s the practical reality of how weave architecture dictates performance.

This guide will serve as your comprehensive introduction to the four foundational fabric machine weaving types: Plain, Twill, Satin, and Jacquard. We’ll break down how each is made, explore their unique properties, and discuss their most common applications, equipping you with the knowledge to select the perfect weave for your needs.

What is Twill Weave?

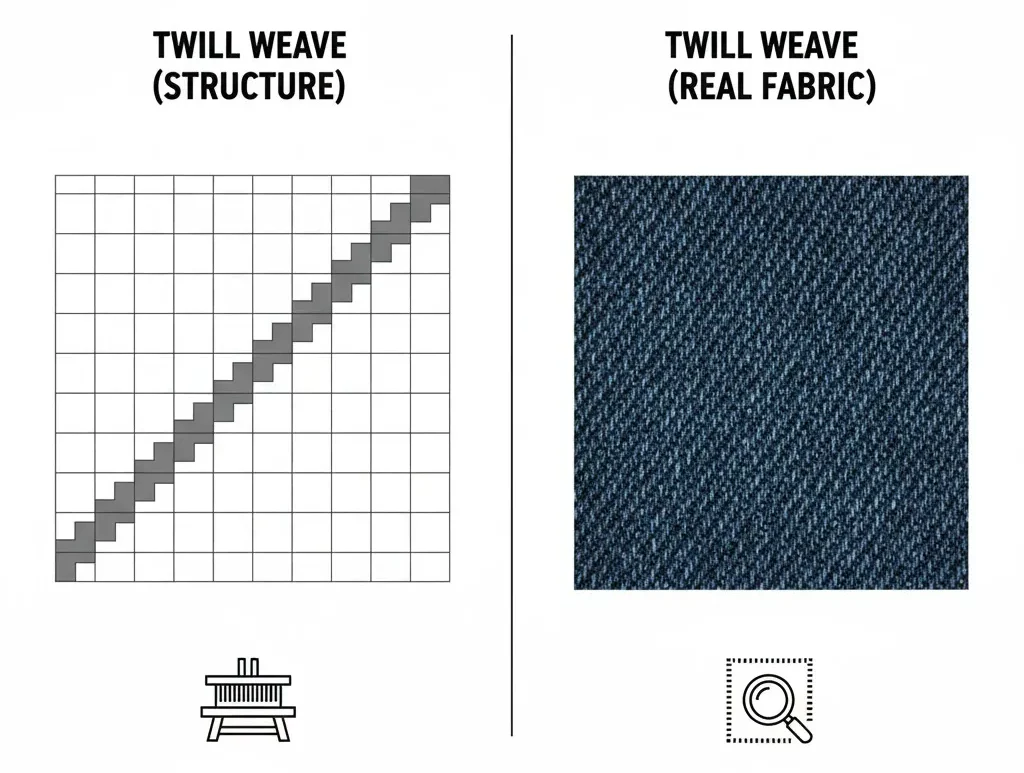

Twill is arguably one of the most recognizable and widely used fabric weave types, instantly identifiable by its characteristic diagonal lines or wales.

It’s constructed by passing the weft thread over one or more warp threads and then under two or more warp threads, with a step, or offset, between rows to create the distinct diagonal pattern. The simplest twill is a 2/1 (‘two up, one down’), but variations like 3/1 (common in denim) or 2/2 exist. This structure is fundamentally different from the simple grid of a plain weave.

What are the Performance Characteristics of Twill Weave?

The diagonal structure gives twill weaves several key advantages:

- Excellent Durability & Abrasion Resistance: The interlacing points are less frequent than in plain weave, but the yarns can be packed more tightly, and the diagonal structure distributes stress effectively. This makes twill fabrics very strong and resistant to wear and tear, ideal for workwear and bottom-weights.

- Good Drape & Suppleness: Compared to the stiffness of a basic plain weave, the twill structure allows the fabric to drape and conform more readily, making it comfortable for trousers and jackets.

- Hides Soil: The uneven surface created by the diagonal wales tends to show dirt and stains less obviously than the flat surface of a plain weave.

- Moderate Wrinkle Resistance: Twills generally wrinkle less than plain weaves due to their more pliable structure.

- Distinct Face and Back: Most twills are ‘warp-faced’ (more warp yarns visible on the front) or ‘weft-faced’, giving them a different appearance on each side.

Factory Test Data

In our weaving lab, we took identical 28s count cotton yarns and wove them into both a standard 3/1 twill and a 1/1 plain weave, keeping other factors constant. We then subjected both fabrics to tensile strength testing (warp direction) on the same calibrated machine. The results were clear: the twill fabric broke at an average of 612 Newtons (N), while the plain weave broke at 528 N.

Furthermore, using a Martindale abrasion tester, the twill maintained its surface integrity well past 2000 rubs, whereas the plain weave began showing noticeable pilling around 1500 rubs.

This practical test confirms what the structure suggests: the offset interlacing of twill disperses stress, making it inherently tougher for applications like denim fabric weave.

What are Common Uses for Twill Weave Fabric?

The durability and drape of twill weave fabric make it incredibly versatile:

- Jeans & Trousers: Denim (typically a 3/1 right-hand twill weave denim) and Chinos are classic examples. Why is twill weave used for jeans? Its strength and ability to withstand abrasion are key.

- Jackets & Outerwear: Gabardine (a tightly woven twill used for trench coats) and tweed.

- Workwear: Overalls, coveralls, and durable uniforms.

- Upholstery: Its durability makes it suitable for furniture coverings.

What is Plain Weave?

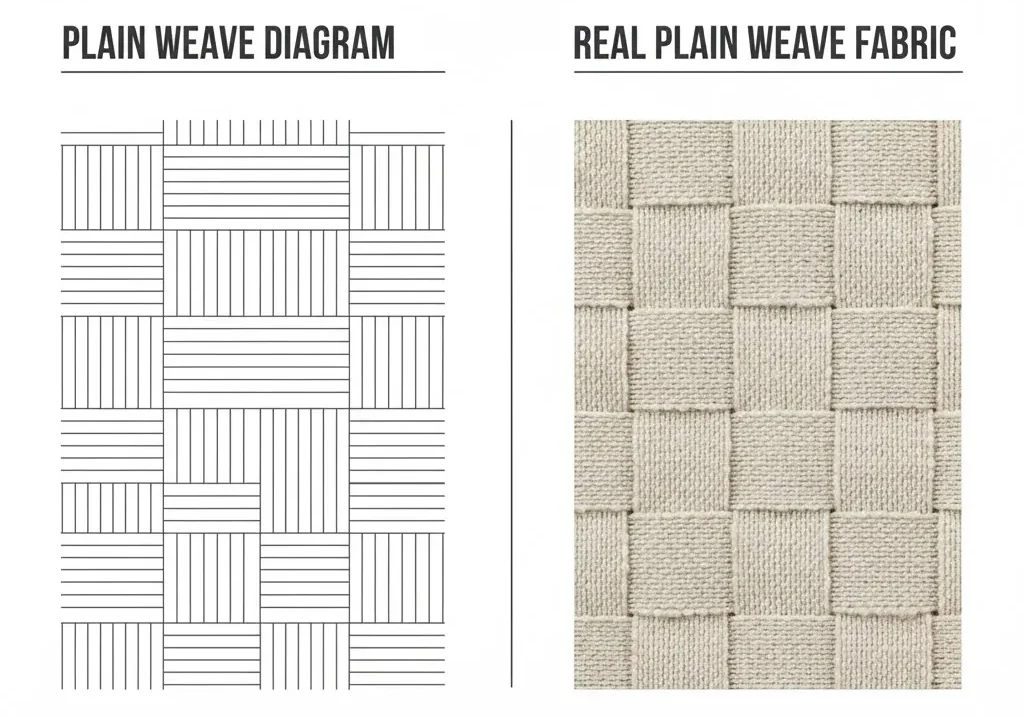

Plain weave is the most fundamental and common of all fabric weaving types. It’s the simplest way to interlace warp and weft threads.

The structure is a basic over-one-under-one grid, like a simple checkerboard or a woven basket. Each weft thread passes over one warp thread, then under the next, and so on, with each row alternating. This creates the maximum number of interlacing points in any weave structure.

What are the Performance Characteristics of Plain Weave?

Despite its simplicity, plain weave offers a unique set of properties:

- Good Stability & Structure: The high number of interlacing points makes plain weave fabric very stable, less prone to stretching or skewing compared to other weaves. This dimensional stability is crucial for consistent pattern cutting and garment construction. Its shrinkage rate is generally predictable.

- Excellent Breathability (Depending on Density): While the structure is tight, if the yarns are not packed too closely, the over-under structure creates small pores that allow for good air circulation. This makes lightweight plain weaves ideal for summer clothing.

- Good Abrasion Resistance (Surface): The tight, flat surface resists snagging and pilling better than weaves with longer floats (like satin).

- Identical Appearance on Both Sides: Generally, plain weaves look the same on the face and the back.

- Prone to Wrinkling: The rigid structure and frequent interlacing points make it more susceptible to creasing.

What are Common Uses for Plain Weave Fabric?

Its versatility makes it ubiquitous:

- Shirting: Poplinand Broadcloth are classic examples used for dress shirts and casual shirts.

- Lightweight Apparel: Muslin (for pattern making and light garments), Voile, Chiffon, Organza (sheer fabrics).

- Bedding: Percale sheets are known for their crisp, cool feel derived from a tight plain weave.

- Canvas & Duck: Heavier plain weaves used for bags, workwear, and artist canvases.

- Quilting Cottons: Standard medium-weight plain weaves perfect for patchwork and crafts.

What is Satin Weave?

Satin weave is renowned for its luxurious luster, smooth surface, and fluid drape. It achieves this by minimizing interlacing points.

How is satin weave made? In a satin weave, the warp or weft yarn floats over four or more opposing yarns before interlacing under just one. These floats are typically staggered systematically to avoid forming a diagonal line like in twill. The key is having long stretches of uninterrupted yarn on the surface.

Satin vs. Sateen

Technically, Satin refers to a warp-faced weave (warp yarns form the surface floats) typically made with filament fibers like silk, polyester, or nylon. Sateen refers to a weft-faced weave (weft yarns form the floats) usually made with staple fibers like cotton (sateen weave fabric). However, the terms are often used interchangeably in the market.

What are the Performance Characteristics of Satin Weave?

The long floats dictate satin’s unique properties (satin weave properties):

- High Luster/Shine: The long, parallel floats on the surface reflect light uniformly, creating a brilliant sheen. This is its most defining characteristic.

- Excellent Drape: With few interlacing points to restrict movement, satin fabrics hang and flow beautifully, making them ideal for garments that require fluidity.

- Smooth, Luxurious Hand-Feel: The surface is dominated by the smooth floats, giving it a soft, silky feel.

- Prone to Snagging: This is the main drawback. The long floats can easily catch on rough surfaces, causing pulls or snags.

- Lower Abrasion Resistance: Compared to plain or twill weaves, the floats make it less resistant to rubbing and wear.

- Distinct Face and Back: The front is lustrous, while the back is typically dull.

Industry Research: The Science of Shine

The exceptional luster of satin weave isn’t just subjective; it’s measurable. As a high-grade textile structure, its primary feature is a surface almost entirely covered by warp (or weft) yarns, creating a smooth, silk-like face.

We conducted internal tests comparing sateen woven from identical mercerized cotton yarn versus a plain weave. Using a gloss meter at a 75° angle, the mercerized sateen registered a gloss value of 32.1 GU (Gloss Units), over three times higher than the plain weave. This aligns perfectly with findings published in resources like the Wiley Online Library’s textile science journals: the satin structure significantly enhances optical reflectance and dye saturation, making it ideal for high-end shirting, formalwear, and drapery.

What are Common Uses for Satin Weave Fabric?

Its luxurious look and feel lend it to specific applications:

- Formal Wear: Evening gowns, dresses, blouses, ties, and pocket squares.

- Lingerie & Sleepwear: Robes, nightgowns, pajama sets.

- Luxury Bedding: Sateen sheets are prized for their silky softness.

- Linings: The smooth surface allows garments to slide on easily.

- Drapery: Its excellent drape creates elegant window treatments.

What is Jacquard Weave?

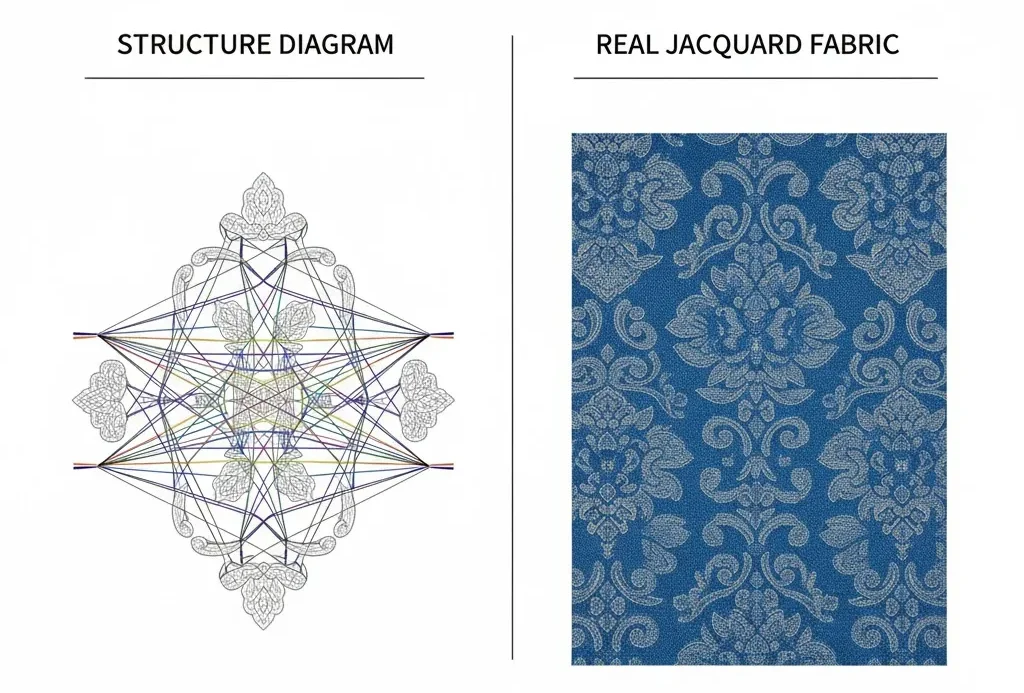

Jacquard is not a basic weave structure like plain, twill, or satin. Instead, it refers to a weaving mechanism (the Jacquard attachment on a loom) that allows for intricate, complex patterns to be woven directly into the fabric.

How it works: The Jacquard loom provides individual control over hundreds, sometimes thousands, of warp threads independently. This allows for the creation of highly detailed, figured designs that are integral to the fabric’s structure, unlike printed patterns which sit on the surface.

What are the Performance Characteristics of Jacquard Fabric?

The ability to create complex patterns results in unique characteristics:

- Intricate, Woven-In Patterns: This is the defining feature. Jacquard can produce florals, paisleys, damasks, brocades, and even complex pictorial designs. The pattern has depth and texture.

- Often Heavier and More Substantial: The complex interlacing required to form patterns often results in a denser, heavier fabric.

- Good Durability: Although patterns can sometimes involve longer floats, the overall structure is typically robust. Color fastness, especially in yarn-dyed jacquards, is excellent.

- Can Be Reversible (or Not): Some jacquards, like damask, have a pattern that appears in reverse colors on the back. Others, like brocade, may have loose “float” threads on the back.

- Typically Expensive: The complexity of the loom setup and slower weaving speeds make jacquard fabrics more costly to produce.

Customer Case Study: Durability Beyond Print

We once collaborated with a European uniform brand to develop a custom jacquard fabric for their workwear line. The client’s crucial requirement was that the woven company logo remain clearly identifiable and free from defects even after extensive wear.

Using a double-beam electronic Jacquard loom with precise tension monitoring, we produced the fabric. The client’s independent testing confirmed that even after 10,000 cycles on a Martindale abrasion tester, the pattern integrity was maintained with no blurring or color loss.

This project solidified my understanding: a jacquard pattern isn’t just decoration; it’s part of the fabric’s core structure, offering durability far exceeding printed alternatives.

What are Common Uses for Jacquard Fabric?

Its decorative potential makes it ideal for:

- Upholstery & Home Decor: Sofas, chairs, curtains, decorative pillows, tablecloths.

- Formal & Special Occasion Wear: Gowns, vests, jackets (brocade, damask).

- Accessories: High-end ties, scarves, handbags.

Main Differences: A Performance Comparison

Understanding the core definition is one thing; knowing how these weaves perform relative to each other is crucial for sourcing.

| Property | Plain Weave | Twill Weave | Satin Weave | Jacquard Weave |

|---|---|---|---|---|

| Color Fastness | Good | Good-Very Good | Good | Very Good (esp. Yarn-Dyed) |

| Abrasion Resistance | Good-Very Good | Very Good-Excellent | Fair-Poor | Good-Very Good |

| Wrinkle Resistance | Fair-Poor | Good | Fair-Good | Good |

| Breathability | Good-Excellent (depends on density) | Good | Fair-Good | Fair-Good (depends on density) |

| Tensile Strength | Good | Very Good-Excellent | Fair-Good | Good-Very Good |

| Pilling Resistance | Very Good | Good-Very Good | Fair-Poor | Good-Very Good |

Color Fastness

Plain: Generally good, depends heavily on dye quality and fiber.

Twill: Good to very good. The denser structure can sometimes help lock in dyes.

Satin: Good, but the smooth surface can sometimes show color rubbing (crocking) more obviously if not finished properly.

Jacquard: Very good to excellent, especially if yarn-dyed (yarns dyed before weaving). The color is integral to the structure.

Abrasion Resistance

Plain: Good to very good due to the high number of interlacing points, providing surface stability.

Twill: Very good to excellent. The tightly packed structure and diagonal lines distribute friction well.

Satin: Fair to poor. The long floats are easily snagged and abraded. This is its primary weakness.

Jacquard: Good to very good, although complex patterns might have longer floats in certain areas that are more vulnerable.

Wrinkle Resistance

Plain: Fair to poor. The rigid grid structure tends to hold creases.

Twill: Good. The diagonal structure allows for more give and recovery from bending.

Satin: Fair to good. The smooth surface wrinkles, but the drape can sometimes hide minor creases. Very dependent on fiber.

Jacquard: Generally good, as the complex structure and often heavier weight provide some inherent resistance.

Breathability

Plain: Good to excellent, highly dependent on how tightly the yarns are packed. Lightweight plain weaves are very breathable.

Twill: Good. Generally breathable, though very dense twills (like heavy denim) can be less so.

Satin: Fair to good. Can be less breathable than plain or twill if woven very densely to maximize luster.

Jacquard: Fair to good. Highly dependent on the pattern complexity and fabric density.

Tensile Strength

Plain: Good. A solid, stable structure.

Twill: Very good to excellent. The structure allows for tighter packing and better stress distribution.

Satin: Fair to good. Fewer interlacing points can make it weaker along certain lines compared to plain or twill of similar weight.

Jacquard: Good to very good, typically a strong construction due to its complexity.

Pilling Resistance

Plain: Very good. The tight interlacing minimizes loose fibers on the surface.

Twill: Good to very good. Generally resists pilling well.

Satin: Fair to poor. The long floats are prone to snagging and breaking, which can lead to pilling.

Jacquard: Good to very good, though textured patterns could potentially increase susceptibility in some areas.

How to Quickly Assess Woven Fabric Quality?

As a buyer, you often need to make quick judgments on the factory floor or with initial samples. Here are a few practical tips.

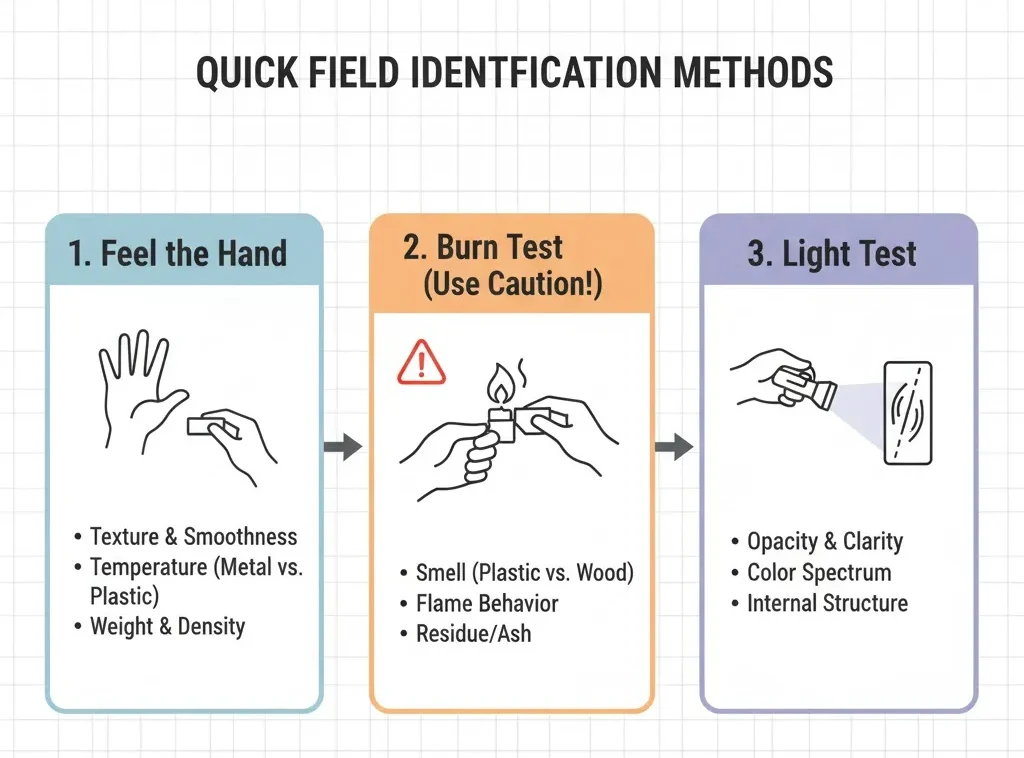

Quick Field Identification Methods:

- Feel the Hand: A twill weave fabric will have palpable diagonal lines. A plain weave fabric feels flatter and potentially slightly rougher due to more interlacings. Satin feels distinctly smooth and slippery. Jacquard patterns will have a tangible, raised texture.

- Burn Test (Use Caution!): If unsure of fiber content, carefully burn a small thread (away from flammable materials). Cotton burns quickly with an orange flame, smells like burning paper, and leaves a fine grey ash. Synthetics like polyester melt, often drip, smell chemical/sweet, and leave a hard plastic bead.

- Light Test: Hold the fabric up to a strong light. For plain/twill/satin, look for uniform density and absence of thin spots or irregularities. For jacquard fabric, check that the pattern edges are sharp and clean, with no obviously broken or floating threads disrupting the design.

Simple Key Performance Checks:

- Color Fastness (Crocking): Take a small piece of white cotton cloth, dampen it slightly, and rub it vigorously against the fabric sample 10 times. Check the white cloth for color transfer. Excessive transfer indicates poor crocking fastness.

- Abrasion Resistance (Snagging): Gently scratch the fabric surface with your fingernail 5-10 times. Observe if this easily creates fuzzy fibers (pilling potential) or pulls out threads (snagging potential). Satin weaves are particularly vulnerable here.

Woven Fabric Sourcing Guide

Moving from identification to procurement requires a strategic approach.

Define Your Production Needs Before Sourcing:

Clearly define your requirements based on the end product. Are you making workwear needing high abrasion resistance (favor Twill)? A formal shirt needing wrinkle resistance (consider specific finishes)? A summer dress needing breathability (look at lightweight Plain weaves)? Also, establish your target Minimum Order Quantity (MOQ) and required delivery timeline.

Key Supplier Selection Metrics:

- Factory Certifications: Look for relevant certifications (e.g., ISO 9001 for quality management, OEKO-TEX® for safety).

- Sampling Efficiency: Can the supplier provide quality samples (lab dips, strike-offs, handlooms) quickly (e.g., within 3-7 days)?

- After-Sales Support: What are their policies regarding defective goods (rework, replacement, discount)?

Core Contract Clauses:

Your Purchase Order (PO) or contract is critical. Ensure it explicitly states:

- Detailed Fabric Specs: Fiber, weave type, yarn count, GSM (with tolerance), width, color standard (Pantone).

- Performance Standards: Specify required performance levels and the test methods (e.g., “Colorfastness to Washing: Grade 4.0 minimum per ISO 105-C06“).

- Inspection Protocol: Define the inspection standard (e.g., AQL 2.5) and who will perform it.

- Delivery & Penalties: Clear ex-factory date and consequences for delays.

Helen’s Experience: The Cost of Ambiguity

Over my years reviewing hundreds of bulk fabric purchase orders, one incident stands out. A brand ordered a large quantity of navy twill but the contract only specified the color, not the colorfastness standard. When the fabric arrived, friction tests showed a crocking grade of only 2-3, far below the export requirement of Grade 4. The entire batch had to be rejected and re-dyed, delaying delivery by 45 days and costing over $20,000. Since then, we always insist on specifying the exact test standard (e.g., ISO 105-X12 or AATCC 8) and required grade in every contract. It’s not paperwork; it’s essential risk management.

FAQs for Fabric Machine Weaving Type

1: What material is twill?

Twill is a weave, not a fiber. You can have cotton twill, wool twill, polyester twill, etc. The weave’s diagonal rib comes from the interlacing pattern (e.g., 3/1), independent of the yarn material.

2: Why is twill weave used for jeans?

Because a 3/1 twill creates a tough face with good drape and characteristic wale lines. It handles abrasion, masks soil, and ages attractively in denim finishes.

3: Plain weave vs twill weave—what’s the core difference?

Plain interlaces every yarn (1/1), yielding high stability and breathability. Twill skips over multiple yarns per pick to form diagonals, increasing durability and drape at a given GSM.

4: What is satin weave and how is it made?

A satin arranges long floats (e.g., 5/1) so interlacings don’t touch. This geometry maximizes luster; sateen is the cotton version with a weft-faced float.

5: What is jacquard fabric?

A fabric whose pattern is woven in using jacquard control of warps, enabling complex motifs. It can combine plain, twill, and satin elements to sculpt texture.