🧥 Introduction: The “GSM Trap” in Flannel Sourcing

In my 20 years of textile manufacturing, the most expensive mistake I see buyers make is sourcing flannel based on GSM alone.

⚠️ The “Summer Shirt” Disaster

I once had a US pajama brand order “160 GSM Flannel,” assuming it would be thick and warm.

When they received the bulk, they were furious. “It’s thin! It feels like a summer shirt!” they claimed.

We pulled the spec sheet. It was indeed 160 GSM, but it was woven with a dense, coarse yarn (low loft) and only lightly brushed. They wanted “warmth,” but they ordered “weight.”

🧬 Decoding the Equation

How to read a flannel fabric spec sheet is not just about checking one number. You must decode the interaction between:

- GSM (Weight)

- Yarn Count (Thickness)

- Density (EPI / PPI)

- Brushing Level (Loft)

✅ Your Technical Translator

This guide is your technical translator. We will move beyond the basics to help you predict warmth, pilling, and shrinkage directly from the spec sheet, ensuring your PO delivers exactly the fabric you envisioned.

⚡ Quick Answer: Spec → What It Means for Performance

Use this table to quickly understand how each spec line impacts the final product.

| Spec Item | What it Controls | What Can Go Wrong (If Ignored) | What to Specify (PO Line) | Quick Check |

|---|---|---|---|---|

| GSM (Weight) | Thickness, Drape, Opacity | Too heavy/stiff or too sheer/thin | 160 GSM ± 5% | Cut 10x10cm & weigh |

| Yarn Count | Softness, Strength, Pilling | Coarse yarns = rough hand; Fine yarns = expensive | 20s x 10s (Warp x Weft) | Lab count test |

| Density (EPI/PPI) | Durability, Wind Resistance | Low density = seam slippage & holes | 64 x 54 (Ends x Picks) | Density glass count |

| Brushing Level | Warmth (Loft), Texture | Too much = pilling/shedding; Too little = cold | Double Brushed (Face/Back) | Handfeel comparison |

📑 What a Flannel Spec Sheet Usually Includes (And What’s Missing)

The Standard List

A standard mill spec sheet typically lists the basics: Fiber Content, Weave, GSM, Width, Yarn Count, Density, and Finish.

⚠️ However, for flannel, the “Standard” sheet is often missing three critical elements:

1. Brushing Level & Side

Many sheets just say Brushed. They don’t specify if it’s single brushed flannel (one side) or double brushed. This changes the handfeel entirely.

2. Tolerances

What tolerances should be in a flannel spec sheet? Without them, a 150 GSM delivery against a 160 GSM order is “technically” acceptable to some mills. You must define the acceptable range (e.g., ±5%).

3. Test Methods

Shrinkage <3%” means nothing if you don’t specify the test. You must cite the standard, such as AATCC 135 (Dimensional Changes of Fabrics after Home Laundering).

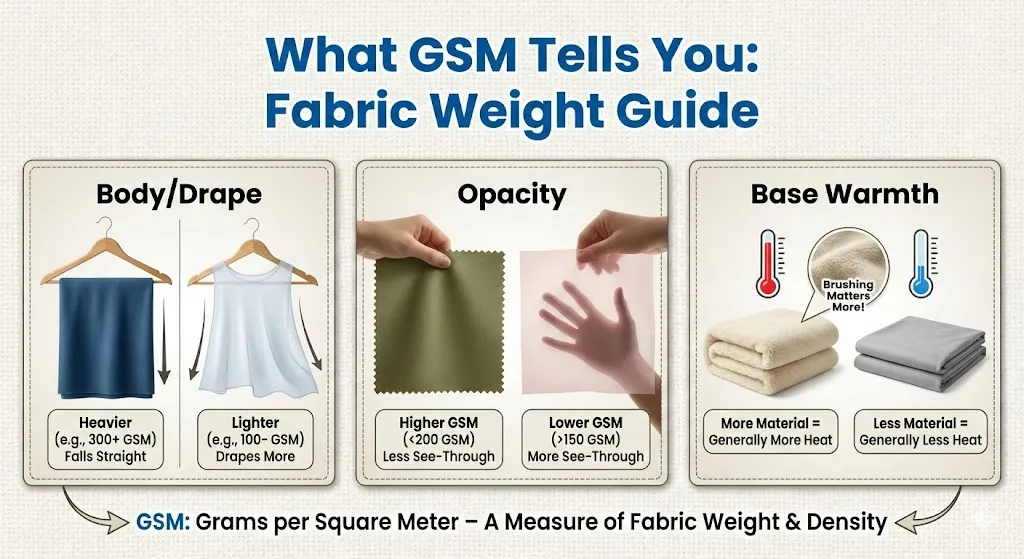

⚖️ GSM / Weight — How to Interpret Flannel Weight Correctly

GSM (Grams per Square Meter) measures mass, not warmth.

What GSM Tells You:

- Body/Drape: Heavier fabric falls straighter; lighter fabric drapes more.

- Opacity: Higher GSM generally means less see-through.

- Base Warmth: More material generally holds more heat, but brushing matters more.

⚠️ Why GSM Alone Is Misleading

Not always. A 180 GSM flannel that is tightly woven and unbrushed will feel colder than a 150 GSM flannel that is double-brushed with a high loft. Brushing creates air pockets (insulation).

Some suppliers use heavy “sizing” (starch) to make a light fabric hit the 160 GSM target. After one wash, it becomes a 140 GSM rag.

✅ Suggested GSM Ranges by End-Use

- 👔 Shirts: 130 – 160 GSM (Light/Mid)

- 🛌 Pajamas: 140 – 170 GSM (Mid)

- 🛏️ Bedding: 160 – 190 GSM (Mid/Heavy)

- 🧣 Throws/Blankets: 200 – 300+ GSM (Heavy)

🧪 How to Verify GSM Quickly (Warehouse Method)

- Cut a sample using a GSM Cutter (100cm² circle).

- Weigh it on a digital scale (e.g., reads 1.60g).

- Multiply by 100 = 160 GSM.

Cut a precise 10cm x 10cm square. Weigh it (e.g., 1.6g). Multiply by 100.

🧵 Yarn Count / Yarn Type — The “Hidden” Driver of Softness & Pilling

Yarn Count (Ne) determines the fineness of the thread. Yarn Type determines the quality.

1. Yarn Count Basics

Higher number = Finer yarn.

- 20s is coarser than 40s.

- 10s is very thick (like rope).

What yarn count is best for flannel shirts? Usually 20s x 10s (Thick weft for brushing) or 40s x 40s (Fine, dressy flannel).

2. Ringspun vs Open-End vs Compact

- Open-End (OE): Cheaper, rougher, weaker. High pilling risk. Avoid for premium flannel.

- Ringspun: Standard for quality. Smoother, stronger.

- Compact: Premium. Lowest hairiness, lowest pilling.

3. Cotton vs Polyester Flannel Yarn

Mimics cotton but pills badly.

Slick, doesn’t pill, but feels like plastic.

4. 📝 What to Write in Spec If You Can’t Lock Exact Yarn Count

If you don’t know the count, specify the outcome:

📏 Density — EPI/PPI (or “High/Medium/Low Density”)

1. What is Density?

Density (Ends Per Inch / Picks Per Inch) is the number of threads in a square inch of fabric.

2. What Density Controls

- 🌬️ Wind Resistance: Higher density = warmer (less air passes through).

- 💪 Durability: Higher density = stronger structure.

- 🧵 Seam Slippage: Low density allows threads to pull apart at the seams.

3. EPI/PPI vs “Thread Count”

Don’t be fooled by high “Thread Counts” (like 1000TC) in marketing. In flannel, a balanced density (e.g., 64×54) is better than a super-high count which makes the fabric stiff and boardy.

4. Common Density Problems

The fabric feels “sleazy” and distorts easily. Brushing can tear holes in it.

The fabric is stiff and won’t drape. Brushing is difficult because needles can’t penetrate the tight weave.

5. Quick Ways to Check Density

Place the 1-inch glass on the fabric and count the threads.

Hold the fabric up to a light. If you see large pinholes of light between threads, the density is low.

🧶 Brushing / Napping Level — The Most Misunderstood Spec

Brushing (Napping) is a mechanical process that tears fibers to create fuzz. It is a “controlled damage.”

1. Single-Brushed vs Double-Brushed

- Single-Brushed: Brushed on one side (usually back).

- Double-Brushed: Brushed on both sides (Face & Back).

2. How Brushing Level Changes Performance

- Softness: Increases.

- Warmth: Increases (More loft).

- Pilling: Does brushing increase pilling risk? Yes, significantly.

- Strength: Decreases (Tear strength drops).

3. How Factories Describe Brushing

Surface feels soft like peach skin (Peached). Pattern is very clear.

Distinct fuzz. Pattern slightly softened. Standard for shirts.

Thick fleece-like surface. Pattern is blurry. Standard for blankets.

4. How to Verify Brushing Level

Can you see the weave clearly? (Light) or is it hidden by fuzz? (Heavy).

Why does flannel look lighter after washing? Heavy napping sheds lint in the wash. Wash a sample and weigh it again.

High weight loss = Poor quality brushing.

🔮 The “Spec Combo” Rules — Predicting Performance

Use this matrix to combine the 4 numbers into a prediction.

| Goal | GSM | Yarn Count | Density | Brushing | Risk Notes |

|---|---|---|---|---|---|

| Crisp Shirt | Light (130) | Fine (40s) | High | Single (Light) | Wrinkling is high |

| Cozy Pajama | Mid (160) | Med (20s) | Med | Double (Heavy) | Pilling is high risk |

| Durable Workwear | Heavy (200) | Coarse (10s) | High | Single (Med) | Stiffness |

| Soft Sheets | Mid (170) | Med (32s) | Med | Double (Med) | Lint Shedding |

🚫 Common Mistakes Buyers Make

1. Only Looking at GSM

The Error: Ignoring density leads to weak fabrics. A heavy fabric with low density will fall apart.

2. Missing “Side” Definition

The Error: Ordering “Brushed” and getting the wrong side brushed. You must specify Face Side, Back Side, or Double Brushed.

3. No Shrinkage Method

The Error: Accepting “3% shrinkage” without knowing the method. 3% Line Dry is very different from 3% Tumble Dry (which might actually shrink 8%).

4. Subjective Terms

The Error: Using vague terms like “Super Soft” in the PO.

The Fix: Always reference a physical “Golden Sample Approval” for handfeel.

🛡️ How to Test Whether the Spec Matches the Bulk (Buyer QC Mini-Plan)

1. Incoming Quick Checks (⏱️ 30 Minutes)

- 📏 Width: Measure inside selvedge. Is it within tolerance?

- ⚖️ GSM: Cut 3 samples (Head, Middle, Tail). Weigh them.

- 🎨 Shading: Check Head vs Tail for color consistency.

- 🧸 Brushing: Compare handfeel to the Golden Sample.

2. Lab Checks (Before Approval) 🔬

- 🧺 Shrinkage: Wash 3 times (AATCC 135).

- ☁️ Pilling: Martindale or Random Tumble (ASTM D3512).

- 💧 Crocking: Rub dry and wet cloth (AATCC 8).

3. Sampling Plan 📦

- 1️⃣ Lab Dip: Color approval.

- 2️⃣ Strike-Off: Print approval.

- 3️⃣ PPS (Pre-Production Sample): Wash test this sample!

- 4️⃣ Shipment Sample: Keep for records.

📝 What to Write in the PO / Spec Sheet (Copy-Paste Template)

Copy this checklist into your Tech Pack.

| Field | Specification | Tolerance |

|---|---|---|

| Fiber Content | 100% Cotton | ± 3% |

| Weave | 2/1 Twill | N/A |

| Weight | 160 GSM | ± 5% |

| Width | 57/58″ (Cuttable) | -0 / +1″ |

| Yarn Count | 20s x 10s | N/A |

| Density | 64 x 54 | ± 2 threads |

| Brushing | Double Brushed (Face/Back) | Match Ref Sample |

| Shrinkage | Warp -3% / Weft -3% | AATCC 135 (Tumble Dry) |

| Colorfastness | Wash 4.0 / Rub 3.0 | ISO 105 Series |

| Pilling | Grade 3.5 Min | ASTM D3512 |

| Shade | Match Lab Dip | Shade Band Req |

| Inspection | 4-Point System | Max 20 pts/100yd |

❓ FAQ (People Also Ask)

1. What does GSM mean for flannel fabric?

Flannel GSM stands for Grams per Square Meter. It indicates the weight and thickness.

- 130 GSM: Light (shirt)

- 170 GSM: Medium (bedding)

- 250 GSM: Heavy (jacket/blanket)

2. Is heavier flannel always warmer?

Not always. Does heavier flannel mean warmer? Usually, yes, but a lighter flannel with double brushing (high loft) can be warmer than a heavy, flat flannel because it traps more air.

3. What yarn count is best for flannel shirts?

What yarn count is best for flannel shirts?

- Standard casual shirt: 20s x 10s or 21s x 21s is ideal.

- Dressy, lightweight flannel: 40s x 40s is best.

4. Does higher density mean less pilling?

Generally, yes. Tighter weaves hold fibers in place better, reducing the loose fibers that form pills.

5. Single vs double brushed: which is better for bedding?

Single vs double brushed: For bedding, double brushed is standard because it provides maximum softness against the skin and maximum warmth.

6. How do I specify brushing level in a PO?

Use specific terms: “Light Nap,” “Medium Nap,” or “Heavy Nap.” Even better, attach a physical swatch and write “Brush to match sample handfeel.”

7. Why does flannel look lighter after washing?

Why does flannel look lighter after washing? Because the brushing process creates loose fibers (lint). The first wash removes this lint, slightly reducing the fabric’s weight.

8. What tolerances should I set for flannel specs?

What tolerances should be in a flannel spec sheet?

- GSM: ± 5%

- Width: -0 / +1 inch

- Shrinkage: Max 3-5% (depending on finish)

9. What’s the difference between peached and brushed?

Peached uses abrasive paper (sandpaper) to create a very short, velvet-like fuzz. Brushed uses wire bristles to pull out longer fibers, creating a fluffier, wool-like texture.

10. How do I prevent shade variation on flannel?

Nap direction & shading is critical. Ensure all rolls are brushed in the same direction and marked. Require a Shade Band approval before bulk shipment.