🔍 Introduction: The Firewall of Quality

For the buyer, the inspection report is the only firewall between a profitable season and a warehouse full of unsellable goods.

⚠️ Why Polyester is Particularly Tricky

Unlike cotton, which hides minor faults in its natural texture, polyester (especially filament types like FDY) is unforgiving.

📘 What is the Four-Point Inspection System?

It is the standard industry method (ASTM D5430) for grading fabric quality by assigning penalty points (1, 2, 3, or 4) to defects based on their size.

It provides a mathematical score to determine if a roll is “Pass” or “Fail.”

✅ For polyester, you must control 3 dimensions:

(Snags, pilling, broken filaments)

(Barre marks, shading between rolls)

(Heat shine, stiff handfeel, stability)

Today, We will break down the Four-Point System, analyze common defects in polyester fabrics, and provide the exact inspection checklists you need to write into your Purchase Orders (PO).

⚡ Quick Answer — Four-Point Inspection System (Snippet Table)

If you are a QC manager or buyer needing a quick reference for defect scoring, use this table. This is the global standard for assigning penalty points.

| Defect Length / Size | Points Assigned | Notes / How to Measure | Examples in Polyester |

|---|---|---|---|

| Up to 3 inches (0–75mm) | 1 Point | Measure along the longest dimension. | Small slub, minor oil spot, single fly yarn. |

| 3 to 6 inches (75–150mm) | 2 Points | Combine multiple small defects in this span. | Moderate scratch, visible coarse yarn, small snag. |

| 6 to 9 inches (150–230mm) | 3 Points | Often indicates a machine issue (e.g., loom stop). | Long snag, dye streak, edge tear. |

| Over 9 inches (230mm+) | 4 Points | Max points per defect is 4. | Continuous runner, full-width barre, large hole. |

| Holes / Tears | 4 Points | Any hole >1 inch is usually 4 points. | Burn holes, torn selvedge, broken needles. |

🏭 Factory Rule of Thumb

Most buyers accept a maximum of 20 to 24 points per 100 square yards for first-quality polyester shirting or lining.

Note:For high-end outerwear, the limit may be as low as 15 points.

📋 How to Run a Four-Point Inspection (Step-by-Step)

Running a proper inspection requires more than just looking at the fabric. It requires a standardized process. Use this checklist to set up your polyester fabric QC requirements.

1. 🛠️ Tools You Need

- ⚙️ Inspection Machine: Must have a backlit screen (for checking pinholes) and overhead light.

- 💡 Lighting Source: D65 (Artificial Daylight) is the standard. TL84 is used for store lighting compliance.

- 📏 Measuring Tape & Stickers: To mark defect locations physically.

- 🎨 Reference Samples: Approved Lab Dip and Handfeel Swatch.

2. ⚙️ Setup (Before You Start)

For polyester, run at 15–20 yards per minute. Faster speeds will miss subtle defects like “Barre” (dye stripes).

Polyester is elastic. Ensure the machine feeds fabric with zero tension to avoid falsifying width measurements.

Define which is the “Face.” For brushed polyester, checking the nap direction is critical.

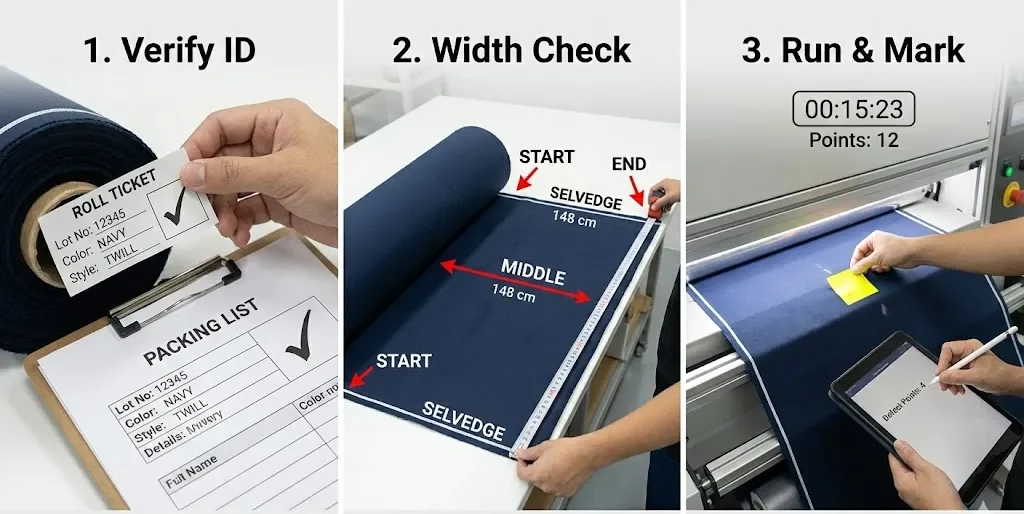

3. 📝 Inspection Steps (Workflow)

- Verify ID: Check the roll ticket against the packing list (Lot No, Color, Style).

- Width Check: Measure the usable width (inside the selvedge) at the start, middle, and end.

- Run & Mark: As the fabric moves, the inspector marks defects with a sticker and records the points.

(Total Points × 3600) / (Fabric Length in Yards × Fabric Width in Inches) = Points per 100 Sq. Yards

- Grade A: Points within tolerance (e.g., <20), no critical defects.

- Grade B: Points exceed tolerance, or contains critical defects (e.g., shading).

4. 🚫 Acceptance Criteria (What to Write in PO)

- 📉 Max Points: 20 points / 100 sq. yards.

- 🔁 Continuous Defects: Any defect repeating for more than 3 yards is an automatic Reject.

- ✂️ Rolls: No roll can contain more than 1 splice (joint).

⚠️ Common Defects in Polyester Fabrics (Snippet Table)

Polyester has specific defects caused by its synthetic nature (static, heat sensitivity, dyeing method).

| Defect Name | What It Looks Like | Where It Comes From | How to Detect Fast | Prevention / Fix |

|---|---|---|---|---|

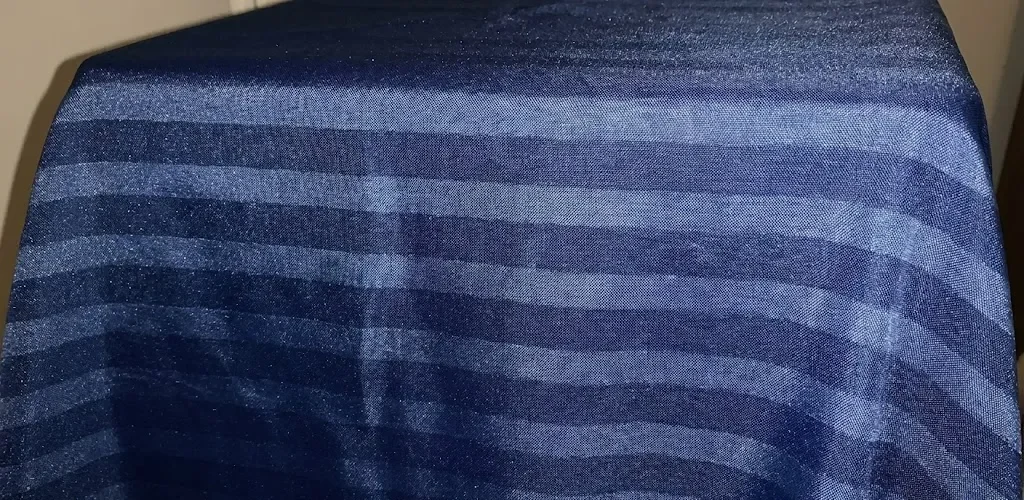

| Barre (Barré) | Horizontal stripes or bands of varying shade. | Yarn mixing (different lots), uneven tension in texturing. | View at 45-degree angle or backlit. | Reject. Cannot be fixed. Prevent with strict yarn lot control. |

| Snagging | Pulled yarn loop on the surface. | Sharp objects in weaving/dyeing; filament yarn is slippery. | Run hand over surface; use Mace Snag test. | Increase twist; use tighter weave; apply anti-snag finish. |

| Pilling | Small balls of fiber on the surface. | Friction; usage of Spun Polyester or DTY. | Rub fabric against itself. | Singeing (gas); anti-pilling enzyme; use high-twist yarn. |

| Heat Shine | Glossy, flattened patches. | Ironing or heat-setting temp too high (Polyester melts). | Look for reflection changes under light. | Control stenter temp; use pressing cloth. |

| Dye Spots | Dark spots of color. | Un-dissolved Disperse Dye particles. | Visual check (usually small dots). | Better dye dispersion; filter dyes; re-wash (sometimes fixable). |

| Static Marks | Dark dust lines or clinging. | Low humidity; static attracts dirt. | Fabric clings to machine. | Anti-static finish; maintain factory humidity. |

📉 Defects More Common in Polyester (Buyer Complaints)

1. Snagging / Pulls (The Filament Curse) 🧶

A loop of yarn is pulled out of the fabric structure.

Polyester filament yarns (FDY/DTY) are smooth and slippery. If a needle or rough surface touches them, they slide out easily.

- Increase the interlacing points (tighter weave).

- Use twisted yarns instead of flat filaments.

Specify “Snagging Resistance: Grade 3.5 min (ASTM D3939).”

2. Pilling / Fuzz Balls ☁️

Balls of tangled fiber.

Polyester fibers are incredibly strong. When they pill, the pills do not break off (unlike cotton pills). They stay attached and look messy. This is common in Spun Polyester and Brushed DTY.

- Singeing: Burn off surface hair.

- Chemical: Apply anti-pilling resin.

Pilling is categorized from Grade 5 (No change) to Grade 1 (Severe pilling). Buyers should insist on Grade 3-4 for polyester garments.

3. Oil Stains / Silicone Spots 🛢️

Dark or translucent spots.

Polyester manufacturing creates high static electricity, which attracts oil mist from looms. Also, knitting machines require heavy lubrication.

Most oil stains on polyester can be removed with scouring agents (degreasers) during dyeing. If seen in finished fabric, it means scouring was poor.

Small spots are 1 point. Widespread spots are a Reject.

4. Dye Unevenness / Barre (The “Tiger Stripe”) 🐅

Repetitive horizontal streaks of light/dark shade.

Polyester dyeing relies on the crystallinity of the fiber. If the yarn tension varied during the spinning or texturing process (DTY), the dye uptake changes.

We once had a claim on 10,000 meters of navy blue polyester taffeta. The fabric looked fine on the inspection table, but when the client made jackets, the sleeves showed stripes. We traced it back to a “mixed merge” of yarn—two different production lots of yarn were used in the weft.

The Fix: Now, we perform a “Head-End Dye Check” on every yarn lot before weaving.

5. Heat Shine / Press Marks ☀️

Shiny areas where the fabric texture has been flattened.

Polyester is thermoplastic. If it is pressed against a hot metal roller or folded while hot, the fibers melt slightly and flatten.

Control the cooling zone temperature in the stenter frame.

6. Color Shading / Lot Variation 🎨

Color difference between rolls or within a roll (Side-to-Center).

Disperse dyes are sensitive to temperature. A 2°C difference in the dye vat can shift the color.

- Use Jet Dyeing machines with rapid circulation.

- Approve a Shade Band (Light-Standard-Dark) before bulk packing.

🎯 Polyester Inspection “Hot Spots” by Fabric Type

Different polyester fabrics carry different risks. Customize your QC checklist based on the type.

1. Polyester Woven (Taffeta / Twill / Ripstop) 🧵

Snagging, Broken Filaments, Slippage.

Perform a “Seam Slippage” pull test on the inspection table. If the yarns slide apart easily, the garment seams will burst.

2. Polyester Knits (Jersey / Interlock) 🧶

Pilling, Spirality (Torque), Needle Lines.

Check for “Torque” (twisting) by laying the fabric flat. Knitted polyester often twists if the yarn was not heat-set properly.

3. Microfiber / Brushed Polyester 🧸

Pilling, Nap Direction, Shedding.

- Use a piece of adhesive tape to check for excessive lint shedding.

- Check that the “Nap” (brushing direction) is consistent roll-to-roll.

4. Coated / Laminated Polyester (PU / TPU) 🧥

Peeling, White Marks (Crazing), Pinholes.

Shine a strong light behind the fabric. Pinholes in the coating will sparkle like stars. These are leakage points for rainwear.

🧮 Defect Scoring Examples (How Points Add Up)

To understand the Four-Point System, let’s look at real-world scenarios from our QC floor.

Example 1: The “Pass” Roll ✅

- 3 small oil spots (<3″) = 3 x 1 point = 3 points.

- 1 coarse yarn (5″) = 1 x 2 points = 2 points.

- Total Points: 5.

Example 2: The “Fail” Roll (High Frequency) ⚠️

- 20 snags (<3″) scattered throughout = 20 x 1 point = 20 points.

- 2 dye streaks (8″) = 2 x 3 points = 6 points.

- Total Points: 26.

Wait, 15.6 is low? Yes, but for Satin, 20 snags is visually unacceptable regardless of the score. Some buyers set a “Max defect count” limit.

Example 3: The “Auto-Reject” 🛑

1 full-width Barre mark repeating every 2 yards.

Even if the points are low mathematically, a repeating defect makes the fabric uncuttable.

📝 What to Write in the PO / QC Agreement (Copy-Paste)

Don’t leave quality to chance. Copy this clause directly into your Fabric Specification Sheet.

❓ FAQ (People Also Ask)

1. What is the four-point inspection system for fabric?

The Four-Point System (ASTM D5430) is a standardized method for grading fabric quality. Inspectors assign penalty points (1, 2, 3, or 4) to visible defects based on their size. The total points per 100 square yards determine if the roll is accepted or rejected.

2. How do you calculate points per 100 square yards?

Points per 100 sq. yd = (Total Penalty Points × 3600) / (Roll Length in Yards × Cuttable Width in Inches)

For metric (points per 100 sq. meters), multiply total points by 10,000 and divide by (Length in meters × Width in mm).

3. What defects are automatic rejects for polyester fabric?

Barre marks (dye stripes), severe shading (color difference within the roll), off-odors, and repeating defects (like a needle line running the full length) are automatic rejects, regardless of the point score.

4. How do you inspect polyester for snagging quickly?

Use a “Glove Test.” The inspector wears a rough cotton glove and lightly wipes the fabric surface. If the glove catches fibers easily, the fabric has poor snagging resistance.

5. What causes barre in polyester fabric?

Barre is caused by physical differences in the yarn (mixing dye lots, different texturing tension) or mechanical issues in knitting (uneven tension feeds). It creates horizontal lines that absorb dye differently.

6. What causes heat shine on polyester and how to prevent it?

Heat shine occurs when polyester fibers (which are plastic) partially melt or flatten under high heat and pressure. It happens during ironing or high-temp calendering. Prevent it by using a Teflon shoe on irons or lowering stenter temperatures.

7. Is pilling a defect in four-point inspection or a lab test issue?

If pilling is visible on the fresh roll, it is a Four-Point defect. However, pilling usually develops after wear. Therefore, it is primarily a Lab Test issue (ASTM D3512) that must be verified on a sample before bulk production.

8. How many points are acceptable per roll?

For standard apparel, 20-24 points per 100 sq. yards is the industry norm. For high-end or expensive fabrics, buyers may demand <15 points. Individual rolls exceeding 40 points are usually rejected.

9. What lighting should be used for fabric inspection?

D65 (Artificial Daylight) is the primary standard for checking color and defects. TL84 (Store Light) is often used to check for “Metamerism” (color changing under different lights).

10. How to control lot-to-lot shading in polyester?

- Use Master Batch yarns if possible.

- Request a Shade Band showing the variation range.

- Ensure the factory segregates rolls by lot number (e.g., Lot A rolls are kept together for cutting).

11. Can oil stains be removed or is it a reject?

Small oil stains on polyester can often be cleaned with a spot gun (using acetone or solvent). However, if the stain is large or the fabric is delicate (like satin) where cleaning leaves a “ring” mark, it is a reject (4 points).

12. What’s the difference between four-point and ten-point system?

The Four-Point System penalizes defects by size (1-4 points). The Ten-Point System is an older method used mostly for heavy canvas/denim, penalizing defects as 1, 3, 5, or 10 points. The Four-Point system is far more common for apparel fabrics like polyester.