👔 In the World of Shirt Manufacturing, a Standard Poplin Doesn’t Exist

I’ve seen buyers order a “standard white poplin” expecting a crisp, opaque dress shirt fabric, only to receive a 95 GSM blouse fabric that is completely see-through. I’ve also seen brands over-spec a casual summer shirt with a dense 120 GSM construction that feels like a raincoat in July.

⚠️ The Reality Check

The difference isn’t quality; it’s specification.

📐 The 3 Control Variables

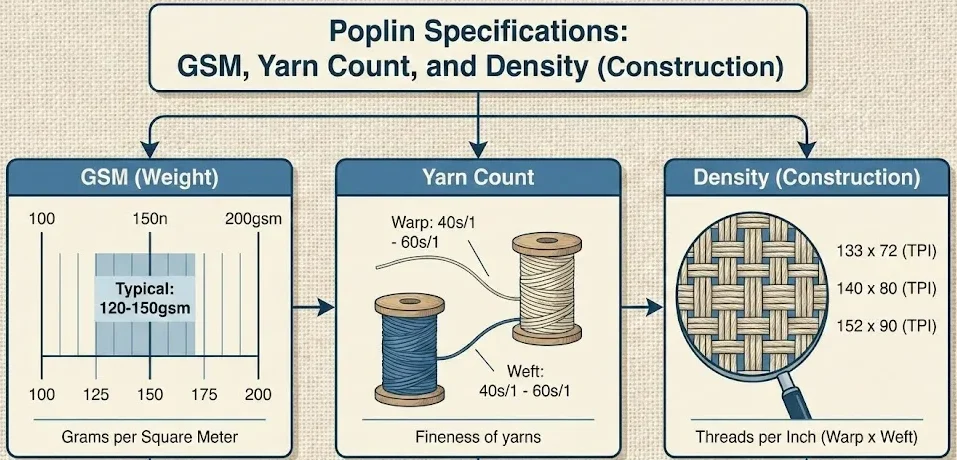

For B2B buyers, mastering poplin shirt specs means moving beyond vague terms like “good quality” and locking down the three variables that actually control the fabric: GSM (Weight), Yarn Count, and Density (Construction).

This guide is your technical manual. Drawing from our factory floor data, we will define the best GSM for poplin shirts, and give you the exact poplin fabric spec sheet templates you need to source safer, smarter, and faster.

📏 Poplin Shirt Specs: Best GSM, Yarn Count & Construction

Poplin shirting specs work best when you pair GSM (fabric weight) with yarn count and fabric density (construction). For shirts, buyers usually choose GSM based on season and opacity, then use yarn count + EPI/PPI to lock in crispness, smoothness, and consistency in bulk.

📐 Table: The Holy Trinity of Poplin Specs

| Lever | Controls | Buyer Goal |

|---|---|---|

| GSM (Weight) | Thickness, Warmth, Drape | Seasonality (Summer vs All-Season) |

| Yarn Count | Smoothness, Refinement, Strength | Handfeel (Crisp vs Silky) |

| Density (EPI x PPI) | Opacity (Cover), Stability | Visuals (See-through vs Solid) |

⚠️ Why Same GSM ≠ Same Fabric

A 110 GSM poplin made with coarse 40s yarn (low density) feels rough and canvas-like. A 110 GSM poplin made with fine 80s/2 yarn (high density) feels silky and refined. You cannot buy on GSM alone.

🎯 The Core Goal

For a dress shirt, you want high density (for a clean look) and fine yarn (for smoothness). For a casual shirt, you might accept lower density for better breathability.

🏭 Factory Reality

Most “quality” issues are actually spec mismatches. The factory wove exactly what was ordered (e.g., 110×70 density), but the buyer expected the coverage of a 133×72 density.

⚖️ What GSM Is Considered Lightweight Poplin for Shirts?

Lightweight poplin for shirts is typically a low-to-mid GSM range chosen for breathability and a crisp handfeel. It’s best for summer shirts and layered styling, but you’ll need enough density (construction) to avoid sheerness—especially in white.

📏 Defining Lightweight

Ultra-Light (85-95 GSM): Very breathable but often sheer. Needs a print or lining.

Lightweight (100-115 GSM): The “Goldilocks” zone for summer dress shirts.

- Is 110 GSM poplin good for shirts? Yes, it is the standard “Light-Mid” weight.

Midweight -120-135 Gsm

Midweight (120-135 GSM): Better for white shirts (opacity) and cooler weather.

⚠️ The Sheerness Risk

Poplin GSM for white shirts is tricky. Below 115 GSM, white poplin will show skin tone unless it has very high density or a special “full dull” yarn finish.

📋 Best For / Not Recommended

Summer casual shirts, printed resort wear, ladies’ blouses.

Unlined white formal shirts (unless high density), heavy-duty workwear.

💡 QC Tip: The “Backlight” Test

Always evaluate poplin GSM for summer shirts under “Daylight + Flash.” A fabric that looks solid on a table can become transparent when backlit by the sun.

👔 What GSM Is Best for a Dress Shirt vs. a Casual Shirt?

Dress shirts usually target a smoother, cleaner surface, while casual shirts can use a slightly heavier or more textured spec for durability and opacity. Use this dress shirt vs casual shirt GSM table to guide your sourcing:

📊 Table: Shirt Type → GSM Goal → Buyer Note

| Shirt Type | GSM Goal | What you’ll notice | Buyer Note |

|---|---|---|---|

| Dress shirt (crisp/clean) | Light–mid (105-120) | Smooth, sharp look | Prioritize yarn count (smoothness) + density |

| Casual shirt (coverage) | Mid (115-135) | Less see-through, sturdier | Prioritize cover factor + shrink control |

| Uniform/work shirt | Mid–higher (125-150) | Durable, consistent | Prioritize inspection + shade control |

💎 The Nuance: Luxury vs. Utility

Even within “Dress Shirts,” a Tuxedo Shirt (Broadcloth style) might be lighter (100 GSM) but use 100s/2 yarn for luxury, while a Daily Office Shirt might be 120 GSM with 40s yarn for durability.

🌦️ Seasonality Adjustments

For poplin GSM for different seasons, shift the target by ~15 GSM. A winter poplin might be 135-140 GSM (often with a brushed finish), while a summer poplin is 105-110 GSM.

⚖️ Does Higher GSM Mean Better Quality for Poplin?

Not always—higher GSM often just means more material per area, which can increase opacity and durability. Poplin “quality” is more reliably driven by yarn quality, yarn count, density (EPI/PPI), finishing, and bulk consistency.

🚫 The “GSM Trap”

Buyers often ask: does higher GSM mean better quality for poplin shirts?

The Analogy: GSM is like the weight of a loaf of bread. A heavy loaf isn’t necessarily tastier; it might just be dense and undercooked.

💎 Low GSM, High Quality

A 100 GSM fabric made from 80s/2 Egyptian Cotton with a Liquid Ammonia finish is luxury quality.

🧱 High GSM, Low Quality

A 140 GSM fabric made from coarse 20s Carded Cotton will feel rough, pill easily, and look cheap despite being “heavy.”

🏭 Factory Experience

We often see buyers request “Heavy Poplin (150 GSM)” for a premium feel. We send a sample using coarse 30s yarn. They reject it for being “too rough.” We then send a 120 GSM sample using fine 60s yarn with high density. They love it.

The Lesson? They didn’t want weight; they wanted the density and structure that usually comes with weight. Don’t confuse the two.

✅ Buyer Checklist: The Real Quality Drivers

- Yarn Quality: Combed vs. Carded (Combed is smoother).

- Spinning: Ring Spun vs. Open End (Ring Spun is stronger).

- Finish: Mercerized vs. Unfinished (Mercerized has luster).

- Consistency: Poplin shade band consistency roll-to-roll.

🧵 What Yarn Count Is Best for Poplin Shirts?

A “best” yarn count depends on the shirt goal: finer yarns usually give a smoother, more refined poplin, while coarser yarns feel more robust and can improve opacity. For buying, treat yarn count as your lever for surface smoothness and crispness, then use density to control coverage.

🔢 Decoding the Numbers

In thread count vs yarn count for shirts, remember: Yarn Count (Ne) describes the thickness of the yarn. Thread Count (TPI) describes the number of yarns.

- 40s & 50s (The Workhorses): Standard for school shirts, corporate uniforms, and mid-range retail. Good balance of strength and cost.

- 60s (Entry-Level Luxury): 60s vs 80s poplin for shirts? 60s is crisp and clean; 80s is silky.

- 80s/2 & 100s/2 (Premium Tier): What does 80s/2 mean? It means two very fine 80s yarns are twisted together to create one strong, smooth yarn. This reduces hairiness (fuzz) and increases durability.

📊 Yarn Count Quick Conversion Table (Approx.)

Formula: Tex = 590.5 / Ne; Denier = Tex × 9

| Cotton count (Ne) | Tex (≈) | Denier (≈) |

|---|---|---|

| 40s | 14.8 | 133 |

| 60s | 9.8 | 88 |

| 80s | 7.4 | 67 |

| 100s | 5.9 | 53 |

Use Case: Use this yarn count conversion Ne to Tex for shirts table when dealing with synthetic blends or European suppliers who use Tex.

🚫 Common Misconception

Is higher thread count always better for shirts?

No. Ultra-high thread counts (like 200s/2) are extremely delicate, wrinkle instantly, and are hard to iron. 80s/2 to 100s/2 is the practical limit for most users.

⚖️ Is Yarn Count or GSM More Important for Opacity?

Opacity is controlled more by cover factor (yarn thickness + fabric density) than by GSM alone. GSM is an outcome; two poplins can share the same GSM but differ in opacity because one uses tighter density or different yarn size/finishing.

🧩 The “Cover Factor” Explained

Does poplin GSM affect opacity? Yes, but density affects it more. Cover Factor calculates how much of the fabric surface area is covered by yarn versus open space.

🔬 Scenario: Same Weight (110 GSM), Different Result

- Weight: 110 GSM

- Yarn: 40s (Coarse)

- Weave: Loose (100×60)

- Result: ❌ Sheer / See-through

- Weight: 110 GSM

- Yarn: 60s (Fine)

- Weave: Tight (150×90)

- Result: ✅ Opaque / Solid

💡 Pro Tips for Opacity

- White Shirts: For poplin GSM for white shirts, specify a High Cover Factor. This usually means increasing the “Ends Per Inch” (EPI) density significantly.

- Finishing Warning: Be careful with “Full Bleach.” Bleaching removes natural impurities but also thins the fiber, reducing opacity. Specifying “Optical White” on semi-bleached fabric is often a safer choice for coverage.

🔗 See our guide on Combed vs. Carded Cotton to understand how yarn choice affects cover.

🏗️ What’s a Common Poplin Construction for Shirts?

A common shirting poplin construction is written as warp yarn × weft yarn / warp density × weft density (EPI × PPI).

Example: 45×45 133×72

This means 45s yarn in both warp and weft, with 133 ends per inch and 72 picks per inch—a classic “crisp shirting” style.

📊 Table: Construction → Feel → Use

| Construction example | What it tends to feel like | Typical shirt use |

|---|---|---|

| 40s x 40s / 133 x 72 | Balanced, everyday crisp | Casual shirts, Uniforms |

| 60s x 60s / 90 x 88 | Smoother, cleaner surface | Dress shirts (Standard) |

| 80s/2 x 80s/2 / 144 x 80 | Silky, high density, premium | Luxury Dress Shirts |

| 45s x 45s / 110 x 70 | Airy, slight texture, budget | Summer Prints, Cheap Promo |

📖 Reading the Spec

133×72 poplin for shirts is the global benchmark. If you see numbers like 110×70, expect a looser, potentially sheerer fabric.

🏭 Factory Insight

We often suggest 80s/2 x 80s/2 for white shirts because the 2-ply yarn provides significantly better coverage (opacity) than a single 40s yarn of the same weight.

👔 Poplin vs. Broadcloth: Are They the Same?

They’re related but not always identical: both can be plain-weave shirting fabrics, but the terminology often signals a difference in handfeel and formality.

🔗 Note: For a detailed breakdown of regional naming differences (US vs UK) and sourcing pitfalls, please refer to our dedicated guide: Poplin vs. Broadcloth Sourcing Guide.

✅ Quick Rule of Thumb

- If you want “crisp structure,” ask for Poplin.

- If you want “smooth luster,” ask for Broadcloth (or High-Count Poplin).

👔 Why Does Poplin Wrinkle—and How Do Buyers Reduce It?

Poplin wrinkles mainly because cotton fibers crease and a crisp plain weave shows folds clearly. Buyers reduce wrinkles by specifying one (or more) of these key levers:

- 1. Easy-care / wrinkle-resistant finish: (The Buyer’s favorite lever).

- 2. Cotton-poly blend: Using synthetic fibers for better crease recovery.

- 3. Construction change: Adjusting density or ply to stabilize the fabric.

- 4. Sanforized / Pre-shrunk: Controls post-wash distortion.

🔬 The “Crispness” Trade-off

Why does poplin wrinkle?

Because the plain weave structure (1-over-1-under) locks the yarns in place. Unlike a twill weave, the yarns can’t slide to absorb the energy of a fold, so the crease sets.

💎 Premium Option (100% Cotton)

Specify a “Liquid Ammonia” (LA) or “Moist Cure” (SSP) finish in your poplin fabric spec sheet. This chemically alters the cotton fiber to resist memory creases without losing the natural feel.

💰 Budget Option

Use CVC (60% Cotton / 40% Poly). The polyester content adds natural resilience and spring-back to the fabric, significantly reducing wrinkling at a lower cost.

🌬️ Is Poplin Breathable for Summer?

Yes—poplin is typically breathable because it’s a plain weave and often used in lighter shirting weights. However, breathability drops if you push density extremely high for opacity, so you must balance airflow vs. coverage.

⚖️ Balancing the Spec

Is poplin breathable for summer shirts? Absolutely. It is the #1 choice.

💨 The Physics: Air Permeability

Breathability is effectively Air Permeability. A standard 133×72 poplin breathes well because air can pass through the weave. A 170×120 poplin (very high density) breathes significantly less because the yarns are packed too tightly.

☀️ Summer Spec Recommendation

- Stick to 100-115 GSM.

- Avoid “Heavy Starch” finishes which can block the pores of the fabric.

Industry Data: According to CottonWorks™ fabric performance data, plain weave fabrics like poplin generally exhibit higher air permeability compared to twills of the same weight because the yarn interlacing points prevent the fabric from packing too tightly, allowing air to pass through.

👻 Is Poplin See-Through? How to Avoid Sheerness

Poplin can be see-through, especially in white/light colors or very light specs.

🛡️ General Strategies to Reduce Sheerness

- Increase cover factor (slightly heavier yarn or tighter density).

- Choose mid-weight instead of ultra-lightweight.

- Avoid overly aggressive singeing/finishing that thins the look.

- Use lining or double-layer design (specifically for whites).

- Confirm with approved swatches under daylight + flash test.

👔 The White Shirt Protocol

How to avoid sheer poplin shirts:

🚫 Don’t just increase GSM

Increasing weight with the same loose weave just makes a heavy, see-through shirt. It does not fix the gaps between yarns.

✅ Increase Density

Move from standard specs (like 110×70) to higher density constructions like 133×72 or 144×80 to close the gaps.

🧵 Use 2-Ply Yarns

80s/2 covers better than 40s. The twisted yarn structure provides more physical bulk and opacity than a single ply.

📰 QC Test: The Newspaper Method

Place the fabric over a printed text (like a newspaper). If you can read the text clearly through the fabric, it is too sheer for an unlined white shirt.

🛡️ Core Fabrics: A “Safe Spec” Strategy

Below is a quick “safe spec thinking” that buyers use: use-case first, then GSM + yarn count + density, then lock tolerances in the PO.

👔 Dress Shirt

Smoothness

115 GSM, 60s x 60s, 144×80 Density

👕 Casual Shirt

Coverage

125 GSM, 40s x 40s, 133×72 Density

⚪ White Shirt

Opacity

120 GSM, 80s/2 x 80s/2, High Density

🏭 Uniform

Repeatability

CVC 45s, 115 GSM, strict shade band

⚖️ How to Test GSM and Confirm Bulk Consistency

🧪 The Lab Standard Method

- Condition: Lay the fabric flat (no tension) to acclimatize.

- Cut: Use a standard GSM cutter to cut a precise area.

- Weigh: Weigh the sample accurately on a digital scale.

- Calculate: Convert weight to GSM (tool-based cutters do this automatically).

- Validate: Repeat 3–5 points per roll (start/middle/end). Record results and compare to the GSM tolerance in the PO.

🏠 How to Measure Fabric GSM at Home

If you don’t have a factory cutter, use this simple formula:

- Cut a precise 10cm x 10cm square.

- Weigh it on a digital jewelry scale (in grams).

- Multiply weight by 100.

Example: 1.2g × 100 = 120 GSM

🏭 Critical Factory Warning

Poplin rolls are woven under high tension.

Always let the sample “relax” on the table for 15 minutes before cutting. Cutting under tension results in the fabric shrinking slightly after the cut, creating a smaller sample that weighs less—giving you a false low GSM reading.

📉 What Shrinkage Spec Should I Put in the PO for Poplin Shirts?

Use a clear clause that states test method + max shrinkage + direction (warp/weft) + responsibility.

👔 Why it matters: Shirts are extremely sensitive to shrinkage because even small changes (like 3%) affect fit, collar sizing, and button placket alignment.

📋 Shrinkage Clause Template (Copy/Paste)

Max -3.0% / -3.0%

AATCC 135 (US) or ISO 6330 (EU/Asia)

After 3 wash cycles at 40°C, tumble dry low

Bulk must meet spec; out-of-spec rolls (>3%) must be replaced or credited.

🎨 What Colorfastness Tests Matter for Poplin Shirts?

For shirting poplin, buyers usually care most about colorfastness to washing, rubbing/crocking (dry & wet), perspiration, and light.

💦 Perspiration

Critical for shirts (armpits/collar). Acid/Alkali perspiration can chemically react with dyes, notoriously causing blue poplin to turn pink over time.

🖐️ Crocking (Rubbing)

Poplin for printing (especially dark prints) needs a Wet Crocking grade of 3.0+ to prevent dye from rubbing off onto other garments (like white pants) or upholstery.

🔗 Learn More: For detailed test methods, read our full guide on Colorfastness to Crocking.

📚 Poplin Shirting Technical Reference Guide

1. The “Holy Trinity” of Poplin Specs

To understand why 95 GSM vs 110 GSM vs 140 GSM poplin for shirts feels different, you must look at how these three levers interact:

| Lever | Controls | Buyer Goal |

|---|---|---|

| GSM (Weight) | Thickness, Warmth, Drape | Seasonality (Summer vs All-Season) |

| Yarn Count | Smoothness, Refinement, Strength | Handfeel (Crisp vs Silky) |

| Density (EPI x PPI) | Opacity (Cover), Stability | Visuals (See-through vs Solid) |

2. Shirt Type → GSM Goal → Buyer Note

| Shirt Type | GSM Goal | What you’ll notice | Buyer Note |

|---|---|---|---|

| Dress shirt (crisp/clean) | Light–mid (105-120) | smooth, sharp look | prioritize yarn count (smoothness) + density |

| Casual shirt (coverage) | Mid (115-135) | less see-through, sturdier | prioritize cover factor + shrink control |

| Uniform/work shirt | Mid–higher (125-150) | durable, consistent | prioritize inspection + shade control |

3. Yarn Count Quick Conversion Table (Approx.)

Formula: Tex = 590.5 / Ne; Denier = Tex × 9

| Cotton count (Ne) | Tex (≈) | Denier (≈) |

|---|---|---|

| 40s | 14.8 | 133 |

| 60s | 9.8 | 88 |

| 80s | 7.4 | 67 |

| 100s | 5.9 | 53 |

4. Construction Library (Construction → Feel → Use)

| Construction example | What it tends to feel like | Typical shirt use |

|---|---|---|

| 40s x 40s / 133 x 72 | Balanced, everyday crisp | Casual shirts, Uniforms |

| 60s x 60s / 90 x 88 | Smoother, cleaner surface | Dress shirts (Standard) |

| 80s/2 x 80s/2 / 144 x 80 | Silky, high density, premium | Luxury Dress Shirts |

| 45s x 45s / 110 x 70 | Airy, slight texture, budget | Summer Prints, Cheap Promo |

📋 A Ready-to-Copy PO Spec Template for Poplin Shirts

Use this template to professionalize your “how to write PO spec for poplin shirts” process:

Poplin Fabric Purchase Order Spec

- Fabric: Poplin (Plain Weave) for Shirts

- Fiber Content: __% Cotton / __% Poly / __% Elastane

- Yarn Count: Warp ___ x Weft ___ (e.g., 60s x 60s)

- Density (EPI x PPI): ___ x ___ (e.g., 144 x 80)

- GSM: ___ gsm (Tolerance ± 5%)

- Width: ___ cm/inch (Cuttable)

- Finish: ___ (e.g., Mercerized + Easy Care)

- Shrinkage: Max 3% Warp / 3% Weft (AATCC 135)

- Colorfastness: Wash 4.0 / Wet Crock 3.0 / Light 4.0

- Shade Control: Poplin shade band approval required

- Inspection: Poplin 4-point inspection; Max points: 20/100yds

🏁 Conclusion

Sourcing the “best” poplin isn’t about finding a magic GSM number. It’s about matching the spec to the shirt.

📝 Sourcing Cheat Sheet

- 105 GSM is your summer best friend.

- 133×72 is your opacity insurance.

- 80s/2 is your luxury ticket.

🛑 Stop Ordering

“Standard Poplin”

✅ Start Ordering

“120 GSM, 80s/2, 144×80 Poplin”

The difference in your final product will be undeniable.

Ready to source precise poplin specs?

Request our “Poplin Construction Master Kit”

Featuring swatches of 40s, 60s, and 80s/2 weights for immediate comparison.