🧵 Introduction: The “Poplin vs Broadcloth” Confusion

In the global textile trade, few terms cause as much confusion as poplin vs broadcloth.

⚠️ The Real-World Risk

I have seen purchase orders held up for weeks because a US buyer requested “Broadcloth” and a UK supplier insisted on calling it “Poplin,” even though they were talking about the exact same roll of white fabric.

For garment factories and B2B buyers, this isn’t just a linguistic debate—it’s a sourcing risk. If you don’t understand the regional and technical nuances, you risk ordering a fabric that is too heavy, too sheer, or made of the wrong fiber entirely.

This guide is written from the factory floor. We will strip away the marketing jargon and look at the difference between poplin and broadcloth through the lens of construction specs, regional terminology, and B2B procurement standards. We will provide you with the exact poplin fabric spec sheet data and PO templates you need to source safely.

🤔 Are Poplin Fabric and Broadcloth Fabric the Same?

Although poplin and broadcloth are often both referred to as “shirting fabrics,” they are not always identical.

Because poplin fabric usually describes a plain-weave fabric with a subtle rib and a crisp feel, while broadcloth fabric often refers to a smoother, tightly woven plain fabric—definitions can vary by region, fiber content, and end use.

💡 Buyer Tip: The safest approach is to specify the weave, weight, yarn count, and finish instead of relying on the name alone.

The Same vs. Similar vs. Interchangeable Matrix

To understand poplin vs broadcloth are they the same, we must look at three layers of reality:

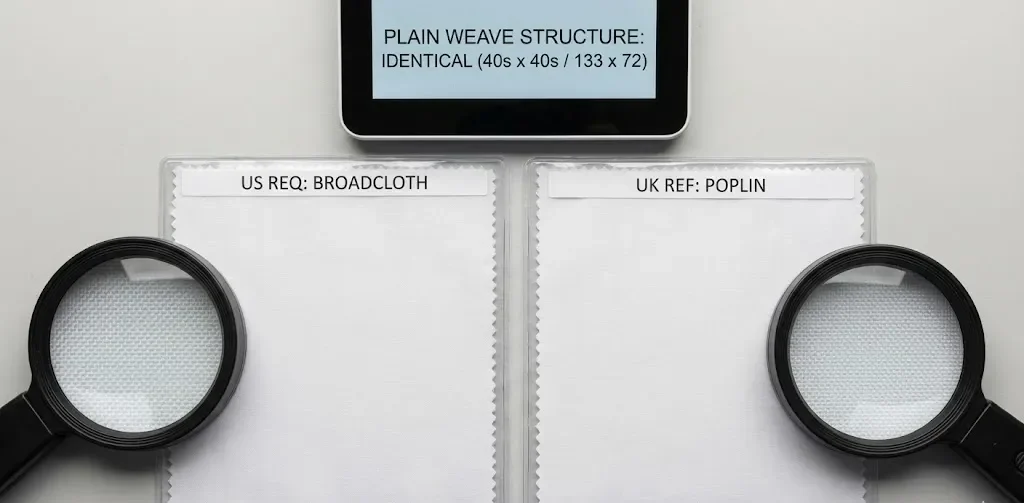

🛠️ Technically Same

In terms of basic weave structure, yes. Both are Plain Weaves (1-up, 1-down structure). In many Asian manufacturing hubs (like our factory in China), the loom setup for a standard 40s x 40s / 133 x 72 construction is identical whether the customer calls it poplin or broadcloth.

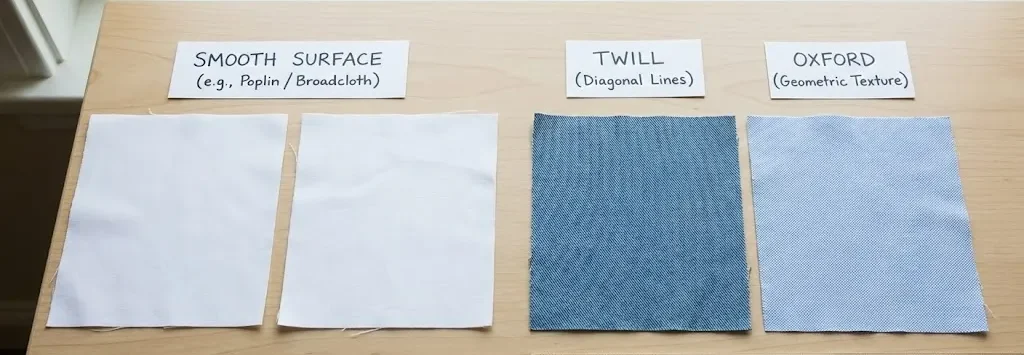

👁️ Visually Similar

Both have a smooth surface without the diagonal lines of twill or the geometric texture of oxford.

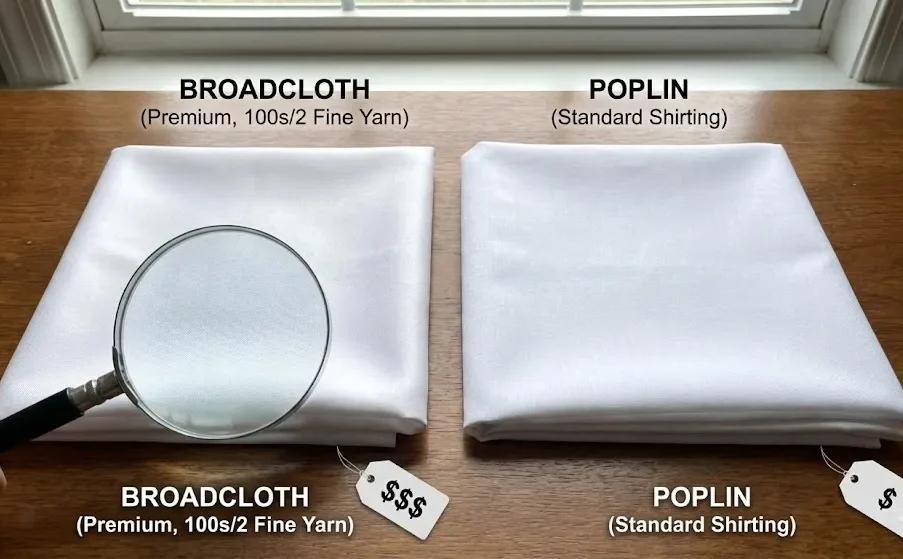

🏷️ Commercially Distinct

In the high-end shirting market, “Broadcloth” is often marketed as a premium, silkier version of poplin, often using finer yarns (like 100s/2).

Why One Fabric Has Two Names?

The confusion largely stems from the evolution of textile trade. Suppliers often use Broadcloth to elevate the perceived value of a standard poplin.

If a fabric is mercerized and has a high thread count, a brand might label it Broadcloth to distinguish it from a basic, crisp Poplin used for school uniforms. However, without a spec sheet, these are just marketing labels.

🤷♂️ Why Do People Mix Up Poplin Fabric and Broadcloth Fabric?

Because both are typically plain weaves used for shirts and uniforms, and many suppliers use the names as “trade labels” rather than strict technical definitions.

In different countries, broadcloth may refer to different fibers or finishes, which adds more confusion.

1. Regional Terminology (The Atlantic Divide)

This is the biggest source of the difference between poplin and broadcloth:

- The US Market: Buyers tend to use “Broadcloth” to describe a high-quality, dressy, plain-weave cotton shirting. “Poplin” is often reserved for slightly heavier or more casual plain weaves.

- The UK/European Market: “Poplin” is the standard term for almost all plain-weave shirting. If you ask for “Broadcloth” in the UK, you might be led to the wool section.

2. The Historical “Wool” Trap

Historically, the term “Broadcloth” referred to a dense, fulled wool fabric produced on wide looms.

In modern shirting, this meaning has shifted entirely to cotton, creating a linguistic trap for those expecting wool.

💡 Sourcing Pro Tip:

This historical context is why what is broadcloth fabric can be a dangerous question if you don’t specify the fiber. In the suiting industry, “Broadcloth” still refers to a dense, felted wool. In the shirting industry, it refers to sleek cotton. Always specify “Cotton Broadcloth” or “Broadcloth Shirting” in your inquiries.

🧵 What Is Poplin Fabric?

Poplin fabric is usually a plain-weave fabric known for a clean look, a slightly crisp hand, and (in many cases) a subtle crosswise rib created by yarn selection and density. In sourcing, poplin is often chosen for shirts, linings, and uniforms where a neat, structured appearance is preferred.

Key Characteristics

- Structure: Is poplin plain weave? Yes. It typically has a higher number of warp threads than weft threads (e.g., 133 warp vs. 72 weft).

- The Rib Effect: Traditionally, poplin used a coarser weft yarn, which created a visible horizontal rib. Modern shirting poplin uses finer yarns, so the rib is very subtle, but the crispness remains.

Variations

- Cotton Poplin: The standard for breathable shirts.

- Poly-Poplin: Common for medical scrubs and durable uniforms.

- Stretch Poplin: Blends 3% elastane for comfort.

👔 What Is Broadcloth?

Broadcloth fabric commonly refers to a tightly woven plain fabric with a smoother surface and a refined, even appearance. Depending on the market, broadcloth may be cotton-based for shirting or a different fiber blend for uniform and lining applications.

Key Characteristics

- Cotton Broadcloth Fabric Meaning: In the context of dress shirts, it implies a fabric where the warp and weft yarns are of similar size and very tightly packed. This reduces the “rib” effect seen in poplin, creating a smoother, flatter surface.

- Broadcloth Fabric for Shirts: It is the go-to for formal events (black tie, weddings) because it typically has more luster than poplin.

- Poly-Cotton Broadcloth: Often used as a cheaper, wrinkle-resistant alternative for corporate wear.

Is broadcloth cotton or polyester? It can be either, or a blend. Always check the composition label.

🔄 Is Broadcloth a Type of Poplin?

In modern trade, broadcloth is not a guaranteed subset of poplin, even though the two can look similar and share plain-weave roots.

The overlap happens when suppliers use broadcloth as a commercial name for poplin-like shirting fabrics, so you should confirm by construction and specs.

Overlapping Specs

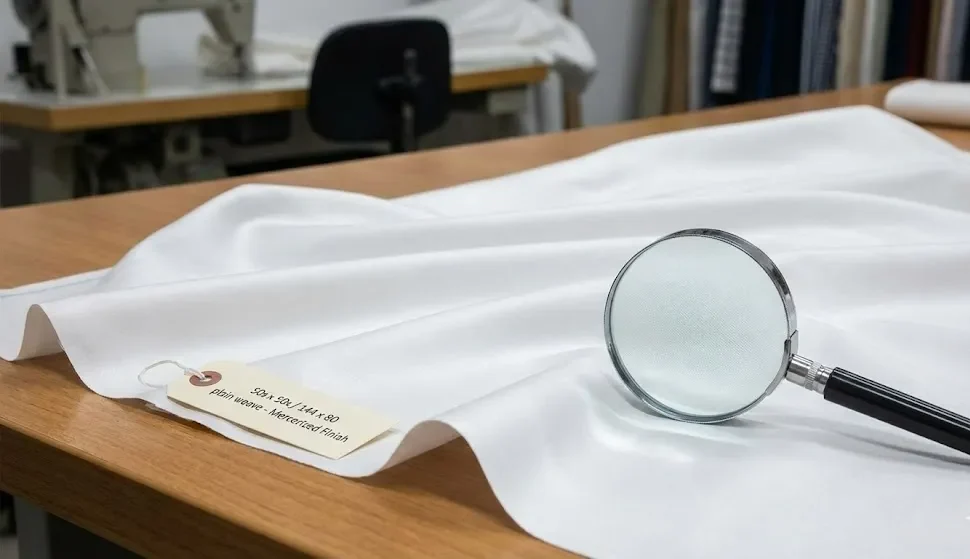

Many B2B buyers ask: is broadcloth a type of poplin? Commercially, they often overlap. A fabric mill might weave a 50s x 50s / 144 x 80 plain weave:

- Brand A (US) sells it as “Premium Broadcloth.”

- Brand B (UK) sells it as “High-Count Poplin.”

- Factory C (Us) calls it simply “144×80 Plain.”

The “Verification” List

Instead of arguing about the name, look for these signs:

- Yarn Count: Broadcloth usually implies finer yarns (50s, 60s, 80s, 100s).

- Finish: Broadcloth often implies a high-luster finish (Mercerized or Liquid Ammonia).

- Density: Both should have high thread counts.

⚖️ Poplin vs Broadcloth—What’s the Key Difference Buyers Should Care About?

The most practical difference is the surface character and handfeel: poplin is often described as crisper with a faint rib, while broadcloth is often described as smoother and more uniform.

For buyers, the deciding factors should be density, finish, and performance specs rather than the label alone.

📋 The Buyer’s Priority List:

- Density: Does the fabric cover the body without being see-through? (See poplin gsm for shirts).

- Finish: Do you need the silkiness of broadcloth or the crispness of poplin?

- Performance: Does broadcloth shrink? Does poplin pill? These are determined by the finishing process, not the name.

☁️ Which One Is Smoother: Poplin or Broadcloth?

Broadcloth is more commonly the smoother option in sourcing, because the term is frequently used for tightly packed, even-surfaced plain fabrics. That said, a finely made poplin with the right finish can feel just as smooth, so sampling is essential.

The Source of Smoothness

When answering poplin vs broadcloth which is smoother, realize that smoothness comes from three factors:

- Yarn Quality: Combed cotton vs. Carded cotton. [Internal Link: /combed-cotton-vs-carded-cotton-differences/]

- Singeing (Gassing): Burning off the fuzz from the yarn surface.

- Mercerization: A chemical treatment that smooths the fiber.

💡 Sourcing Reality: A “Poplin” that is double-mercerized will be smoother than a “Broadcloth” that is only semi-bleached.

📐 Which One Feels Crisper or More Structured?

Poplin is more often associated with a crisp, structured hand that holds shape well, especially in classic shirting. However, broadcloth can also be crisp if the finish and density are built for structure, so confirm by spec and hand evaluation.

The Structure Factor

- Poplin Handfeel: Famous for being crisp. This makes it ideal for sharp collars and cuffs. If you want a shirt that stands up on its own and looks freshly pressed (even if it wrinkles later), Poplin is the traditional choice.

- Broadcloth Handfeel: Being slightly drapier and silkier, it is less stiff and flows better over the body.

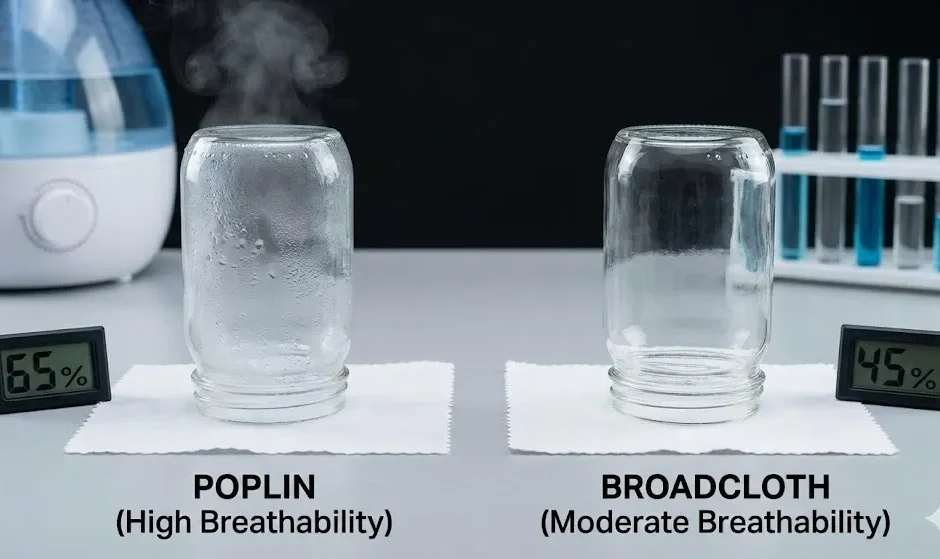

🌬️ Which Is More Breathable for Shirts?

Breathability depends more on fiber content, yarn size, and fabric density than on whether it’s called poplin or broadcloth. A lighter, more open cotton construction will typically breathe better than a denser fabric, regardless of the label.

🧪 The Physics of Airflow

Breathability isn’t just a feeling; it’s physics. According to CottonWorks™ technical guides on fabric performance, air permeability is directly inversely proportional to the ‘Cover Factor’ (density).

A high-density broadcloth (e.g., 100s/2 with high thread count) will naturally be less breathable than a standard 40s poplin, regardless of the name. If breathability is your #1 goal, look for lower density, not a specific name.

(Learn how yarn count affects airflow in our guide: yarn-count-and-weight-quick-guide)

The Checklist for Breathability

- Is poplin breathable? Yes, very.

- Is broadcloth breathable? Yes, but slightly less than poplin if it is very high density.

- Fiber: 100% Cotton breathes best. CVC blends breathe well. High-poly blends trap heat.

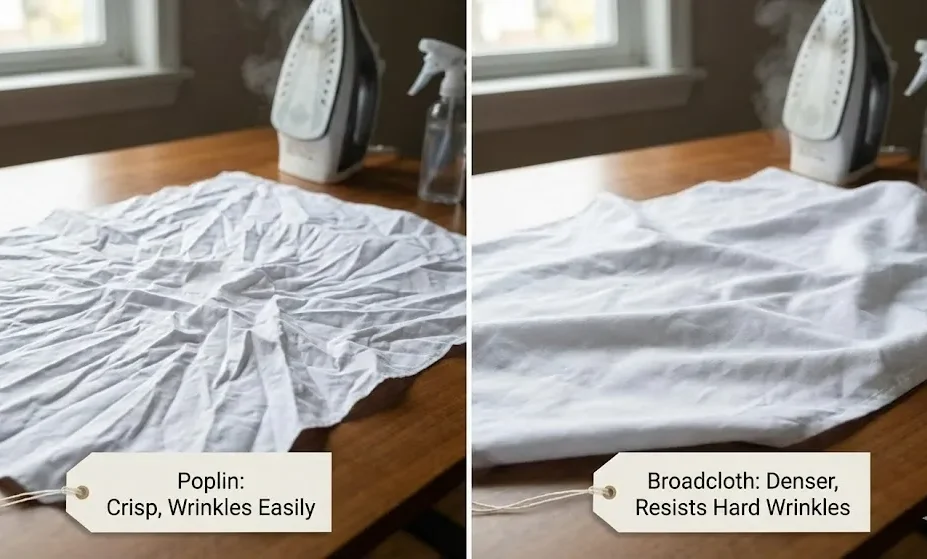

🧺 Which Wrinkles More—Poplin or Broadcloth?

Wrinkling is mainly controlled by fiber and finish, not the name. Cotton versions of both fabrics can wrinkle noticeably, while easy-care finishes or blended fibers can reduce wrinkling for either poplin or broadcloth.

Managing the Wrinkle Risk

Buyers often ask: does poplin wrinkle? or does broadcloth wrinkle?

The answer for both is YES, if they are untreated 100% cotton. The plain weave structure (one-over-one-under) is the most prone to wrinkling because the yarns are locked tight and cannot shift to absorb stress.

✅ Solution:

Specify an Easy-Care, Wrinkle-Free, or Liquid Ammonia finish in your PO.

🎨 Which Is Better for Printing and Solid Dyeing?

A smoother, more uniform surface tends to print cleaner and show solid shades more evenly, which is why many buyers prefer broadcloth-style surfaces for certain prints. Still, well-finished poplin can also perform great—request strike-offs or lab dips to confirm.

Surface Uniformity

- Solid Dyeing: Broadcloth is often preferred for solid dark colors (Navy, Black) because its smooth surface reflects light evenly, creating a richer color depth.

- Printing: Both are excellent for Digital Printing (DTG) or Screen Printing.

✅ Action Item:

Always request a Lab Dip (for solid) or Strike-Off (for print) to check clarity before bulk production.

👮 Poplin vs Broadcloth for Uniforms—What Should You Choose?

For uniforms, choose based on durability, appearance retention, and care requirements rather than the fabric name. A denser plain weave with stable finishing and clear performance specs usually outperforms a loosely specified “poplin/broadcloth” label.

✈️ Industry Case Study

We once worked with a major airline uniform project that initially requested “Poplin” for their pilot shirts. However, after 3 months of wear trials, the shirts showed signs of pilling and transparency.

We switched them to a high-twist “Broadcloth” spec (CVC 60/40) with a Liquid Ammonia finish. The result? Pilling complaints dropped by 90%, and the shirts maintained their whiteness longer.

📋 The Uniform Buyer’s Priority List:

- Pilling: Does poplin pill? Does broadcloth pill? If the yarn is short-staple, yes. Specify “Combed Cotton” or “Vortex Spun Poly-Cotton” to prevent this.

- Opacity: Uniforms must not be see-through. Broadcloth (being generally denser) often wins here.

- Durability: Poplin vs broadcloth for uniforms often comes down to the blend. A CVC Broadcloth is the industry workhorse.

⏱️ How to Choose in 30 Seconds—3 Buyer Rules

Use poplin when you want a neat, crisp look with a slightly structured feel, and use broadcloth when you want a smoother, more uniform surface. If you’re unsure, buy by fiber + weight/density + finish, then approve by sample and test results.

Here are the rules to simplify how to choose your fabric:

Rule 1: Define the End Use

- School Uniform / Basic Shirt → Poplin (Cost-effective, crisp).

- Tuxedo Shirt / Executive Wear → Broadcloth (Lustrous, smooth).

Rule 2: Define the Performance

- Hot Climate → Poplin (Generally lighter/more breathable).

- Opaque / Durable → Broadcloth (Higher density).

Rule 3: Ignore the Label, Trust the Hand

Request samples of both. Blind test them. Choose the one that feels right for your brand.

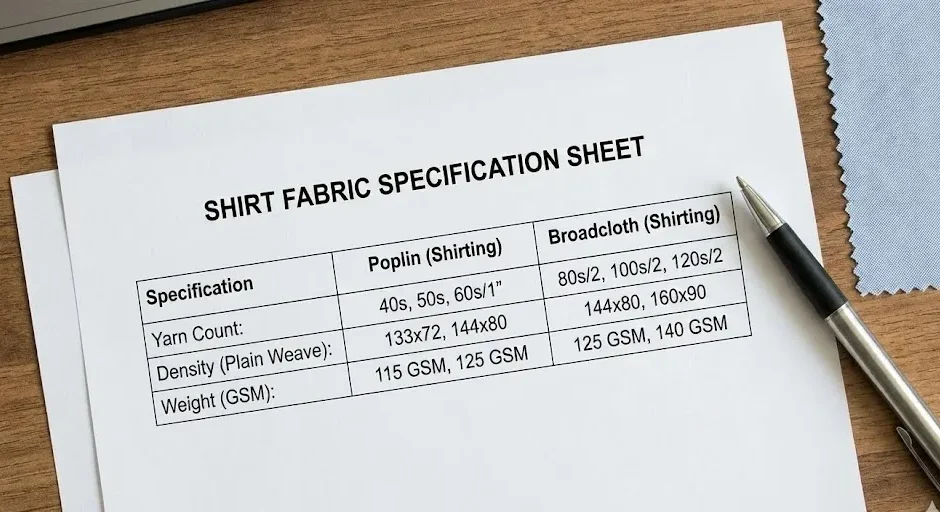

🛡️ The Safest Way to Buy—Specs That Matter More Than the Name

Names are inconsistent across suppliers, but specs are measurable and enforceable. If you lock fiber content, construction basics, finishing requirements, shrinkage tolerance, and colorfastness targets, you can source consistently even when suppliers label fabrics differently.

📊 Industry Data

Data from ASTM International testing standards (specifically ASTM D3775 for Warp and Filling Count) shows that commercial “Poplin” and “Broadcloth” samples often have identical thread counts (e.g., 144×80).

Relying on the name alone has a 0% correlation with technical performance in blind tests. You must buy based on the poplin fabric spec sheet data.

The Key Specs:

- Yarn Count: e.g., 40s, 50s, 80s/2. (poplin yarn count for shirting)

- Density: e.g., 133×72, 144×80. (shirt fabric plain weave specs)

- Weight: e.g., 115 GSM, 125 GSM. (poplin gsm for shirts, broadcloth gsm for shirts)

(Detailed sourcing strategies found here: strategic-cotton-sourcing-guide)

📝 What to Write in Your PO—Poplin/Broadcloth Spec Template

A good PO avoids relying on the word “poplin” or “broadcloth” alone and instead specifies construction, finish, and measurable performance targets. When suppliers quote with the same specs, you prevent “same name, different fabric” problems at bulk production.

Copy this template to professionalize your how to write PO for poplin fabric process:

📄 PO Specification Template

- Fabric Name:

Poplin / Broadcloth (Plain Weave) - Fiber Content:

___% Cotton / ___% Polyester / ___% Elastane - Yarn Count:

Warp ___ x Weft ___ (e.g., 40s x 40s) - Density:

Warp ___ x Weft ___ (e.g., 133 x 72) - Construction Notes:

Plain Weave; Surface Requirement (Smooth / Slight Rib Acceptable) - Weight:

Target ___ GSM + Tolerance +/- 5% - Width:

Usable Width ___ inches + Tolerance - Finish:

Singed / Mercerized / Easy-Care / Liquid Ammonia - Shrinkage:

Test Method (ISO 6330) + Max Allowance (e.g., +/- 3%) - Colorfastness:

Method (AATCC/ISO) + Target Grade (e.g., Grade 4) - Pilling/Abrasion:

Method + Target - Shade Control:

Shade Band / Lot Control Required - Inspection:

4-Point System / AQL 2.5 - Approval:

Lab Dip / Strike-Off / Pre-Production Sample Required

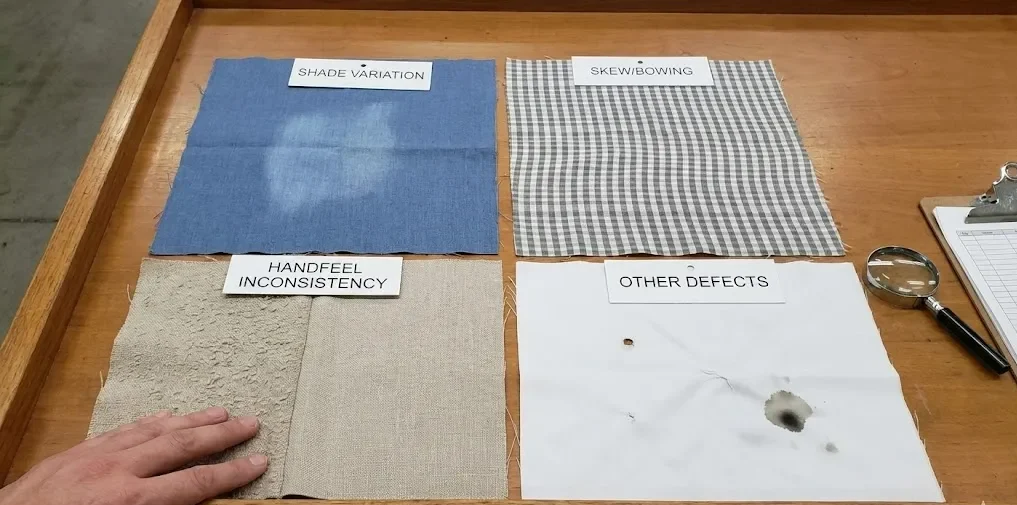

🔍 Common Quality Issues and How to Inspect Quickly

Most “poplin/broadcloth problems” are actually spec or process issues: shade variation, skew/bowing, inconsistent handfeel, and unexpected shrinkage are the most common. A quick roll inspection plus clear test requirements catches these early before cutting and sewing.

(See our full guide on inspection: common-denim-fabric-defects-guide)

The Quick Inspection Checklist

- Shade Variation: Check the “Center-to-Selvedge” (CSV) shading. Poplin/Broadcloth is prone to shading if the dyeing padder pressure isn’t even.

- Skew/Bowing: Because plain weaves are tight, they can distort. Check if the weft yarn is perpendicular to the selvedge.

- Handfeel Consistency: Compare the bulk roll to your approved “Handle Sample.”

- Defects: Look for “Weaving Bars” (horizontal lines) which are very visible on smooth broadcloth.

🏁 Conclusion: Semantics vs. Science

In the end, the battle of poplin vs broadcloth is a battle of semantics, not science.

Poplin

Usually implies crisp, practical, and standard.

Broadcloth

Usually implies smooth, lustrous, and premium.

The Reality

But to a loom, they are both plain weaves. As a smart buyer, your job is to ignore the label and focus on the specs. Define your yarn count, set your density, and choose your finish.

Whether you call it Poplin, Broadcloth, or simply “Code 13372,” we have the machinery to weave it to your exact standard.