👔 Introduction: The “Big Three” of Shirt Fabrics

In the global menswear market, over 90% of dress shirts are made from just three fundamental fabrics.

For a startup brand or a seasoned sourcing manager, choosing between Poplin, Oxford, and Twill is the first and most critical decision in product development. As a factory with 20 years of fabric manufacturing experience, we understand how fabric determines the success or failure of a product line.

Why it matters: Choosing the wrong fabric as the base for clothing not only means sacrificing comfort but also significantly reducing quality, losing customer reputation, and even weakening the entire line’s market competitiveness.

🏭 Factory Insight

When a customer asks “What fabric is the shirt made of?” our answer isn’t just “cotton.” Our answer should be: “What really gives the shirt its soul is the specific structure of the yarns interwoven – the weave.”

Today I will combine my experience in fabric production over the past 20 years to give you an in-depth analysis of Poplin vs Oxford vs Twill. I will start with the basic definition, then move on to the fundamental differences, and finally explain how garment factories should make bulk purchases based on their cost structure, production efficiency, and market demand.

🧶 Definitions: Decoding the Weave Structure

Before comparing costs, we must define the technical architecture. Understanding the different types of weave is essential for writing an accurate Tech Pack.

1. What is Poplin? (The Crisp Plain Weave)

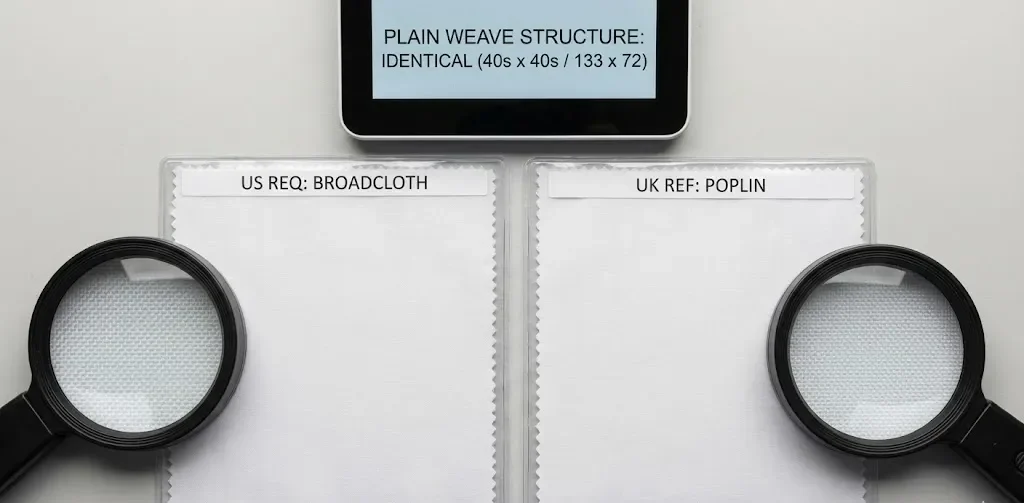

Poplin shirt meaning: Poplin (also known as Broadcloth in the US) is the quintessential dress shirt fabric. It features a tight Plain Weave.

Structure: It uses a simple “one over, one under” interlacing pattern. The key characteristic is that the warp density is significantly higher than the weft density (often double). This creates a very fine, almost invisible horizontal rib or ridge.

The Result: A poplin textile is smooth, cool to the touch, and structurally stable. It is the standard for formal business wear.

(For a deep dive into its production, read our dedicated guide: what-is-poplin-fabric)

2. What is Oxford? (The Basket Weave)

Oxford cloth characteristics: Oxford is defined by a Basket Weave.

Structure: Instead of a single thread, pairs of warp threads cross over pairs of weft threads (usually 2×2). Crucially, Oxford is almost always a “Yarn-Dyed” fabric, meaning the warp threads are dyed a color (like blue) and the weft threads are left white.

The Result: This creates the iconic “dot” texture or checkerboard appearance. It is generally heavier and more substantial than poplin.

Variations:

- Pinpoint Oxford Fabric: Uses finer yarns and a tighter 2×1 weave. It bridges the gap between casual Oxford and formal Poplin. Pinpoint oxford weave is smoother and more suitable for business casual.

- Royal Oxford Fabric: The most complex and textured, using a fancy weave that creates a diamond-like effect. It is incredibly soft and lustrous.

3. What is Twill? (The Diagonal Weave)

Twill shirt definition: Twill is easily identified by its diagonal lines or “wales” on the fabric surface.

Structure: The weft thread passes over one or more warp threads and then under two or more, with an offset in each row. Common twill fabric types for shirts include Fine Twill, Herringbone, and Cavalry Twill.

The Result: Because the yarns can be packed closer together, it creates a durable twill fabric that is thicker, softer, and drapes better than poplin.

(Understand the mechanics of this weave in our fabric-machine-weaving-types-plain-twill-satin-jacquard-explained guide.)

⚖️ The Core Comparison: Poplin vs Oxford vs Twill

To choose the best fabric for dress shirts for your line, you need to compare their physical performance.

| Feature | Poplin | Oxford | Twill |

|---|---|---|---|

| Weave Structure | Plain Weave (1×1) | Basket Weave (2×2) | Diagonal Weave (2×1, 3×1) |

| Texture | Smooth, flat, crisp | Textured, dotted, matte | Soft, diagonal lines, slight sheen |

| Breathability | Excellent (Highest) | Good (Pinpoint is better) | Moderate (Denser) |

| Weight (GSM) | Light (100-120 GSM) | Medium/Heavy (140-180 GSM) | Medium (120-150 GSM) |

| Wrinkle Resistance | Poor (Wrinkles easily) | Fair (Resists creases better) | Good (Resists wrinkles best) |

| Transparency | Can be sheer (especially white) | Opaque | Opaque |

| Durability | Good | Excellent (Very strong) | Very Good |

| Best Season | Summer / Hot Climates | All Season / Winter | All Season / Cooler Climates |

Analysis:

☁️ Softness

If you need a soft shirt material, Twill is generally the winner due to the lower interlacing points allowing yarns to move freely. Royal Oxford is also exceptionally soft. Poplin is crisp, not soft.

🌬️ Breathability

For a breathable shirt fabric or breathable material for shirts, Poplin is the undisputed king. Its thin structure allows maximum airflow. Heavy Oxford can be too warm for summer.

🎨 Texture

If you want shirts with texture, Oxford provides a visual “dot” effect, while Twill provides a subtle sheen and depth. Poplin is flat.

💰 The Economics of Sourcing: Cost, Price & Production

This section is for the buyers. The price on the tag starts with the cost of the weave. We will break down the financial implications of poplin vs oxford shirt production.

Raw Material Costs

Poplin (Lowest to Medium Cost):

Poplin is often Piece-Dyed (woven white, then dyed). This allows for lower yarn inventory costs. We can use standard 40s or 50s single yarns for mass market, or 80s/2-ply for high-end. The versatility keeps costs manageable.

Twill (Medium Cost):

Twill requires a higher thread count (density) to maintain its structure compared to a plain weave. More yarn per meter = higher raw material cost. It also often requires higher quality, cleaner cotton to show off the diagonal line clearly.

Oxford (Highest Cost for Same Count):

Why is Oxford often more expensive? Because it is primarily Yarn-Dyed. We must dye the yarn before weaving. This increases the lead time and the MOQ (Minimum Order Quantity). Furthermore, Oxford often uses specific, thick-and-thin yarns to achieve its texture, which can be costlier to spin. Heavy oxford cloth shirts use significantly more cotton by weight (higher GSM).

Processing & Finishing Costs

Poplin: To answer “is a poplin shirt great quality?”, it depends on the finish. High-end poplin almost requires Mercerization and Liquid Ammonia finishing to reduce wrinkling and add luster. These finishes add $0.30-$0.50 per meter to the cost.

Twill: Often requires less aggressive finishing because it naturally resists wrinkles and drapes well. However, “Non-Iron” dips are common for twill corporate wear, adding cost.

Oxford: Usually undergoes a simple soft wash or enzyme wash. The processing cost is generally lower than a high-spec silky poplin.

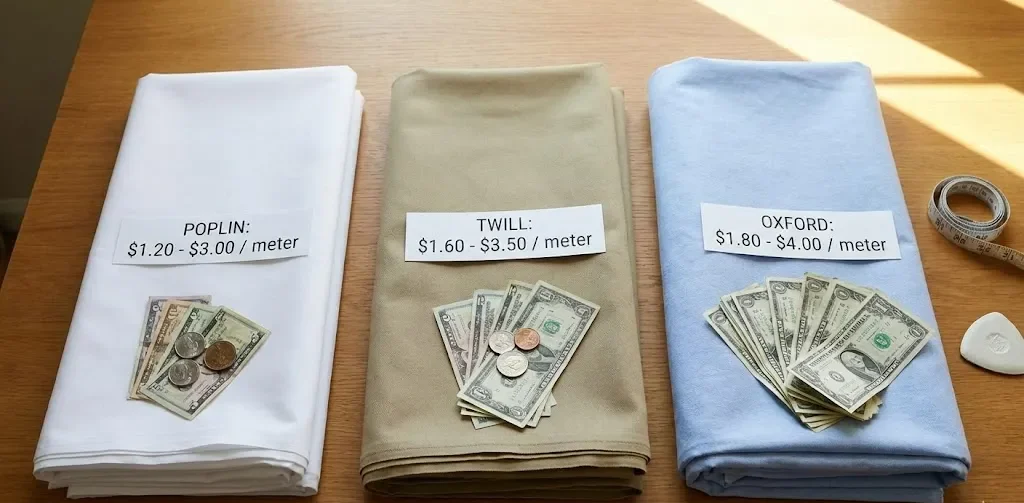

Wholesale Price Range (Estimates)

- Poplin: $1.20 – $3.00 / meter (Wide range due to yarn count variations).

- Twill: $1.60 – $3.50 / meter.

- Oxford: $1.80 – $4.00 / meter (Pinpoint and Royal Oxford command premiums).

🏭 Industry Application Scenarios: Poplin vs Oxford vs Twill

How do you match the fabric to the specific industry need?

1. Poplin

- Target Industry: Formal Business Wear, Banking, Uniforms (Aviation/Hospitality).

- Procurement Requirement: High yarn count (80s/2, 100s/2) for executives; Standard (40s, 50s) for staff. Must specify “Wrinkle-Free” or “Easy Care.”

- Suggested Cooperation: Plan for large volume, piece-dyed programs. You can book greige fabric in advance and dye colors as trends change.

💼 Client Case: When Poplin Was Too Sheer for a Corporate Uniform

A few years ago, a European corporate uniform client approached us with a brief for white business shirts for a financial institution. The original Tech Pack specified a lightweight Poplin because the team wanted “a very cool, breathable shirt fabric for summer.”

⚠️ The Hidden Issue

On paper, the spec looked fine. The fabric passed all lab tests for strength and shrinkage. But when we cut full-size samples and tried them under office lighting, a problem became obvious: the shirts were simply too sheer for a conservative corporate environment. The underwear was clearly visible through the fabric, which was inconsistent with the brand image.

🛠️ Our Consulting Approach

Instead of forcing the original Poplin through production, we sat down with the client and re-worked the base quality:

- We slightly increased the gsm.

- We adjusted the yarn count and density.

- We explored a fine Twill option as a backup.

✅ The Outcome

In the end, they chose a slightly heavier Poplin for summer and a fine Twill for cooler months. The result: the line kept the crisp, formal look they wanted, but complaints about transparency dropped to almost zero after launch.

2. Oxford

- Target Industry: Tech Industry Uniforms, Casual Retail Brands (e.g., Ralph Lauren style), University Merch.

- Procurement Requirement: Focus on the “Yarn-Dyed” look. For premium lines, source Pinpoint Oxford weave. For rugged looks, source Heavy oxford cloth shirts.

- Suggested Cooperation: Requires longer lead times due to yarn dyeing. Plan seasonal colors 3 months in advance.

3. Twill

- Target Industry: Corporate Uniforms (Sales teams), Luxury Winter Shirts, Brands focusing on Non-Iron.

- Procurement Requirement: Focus on opacity (white shirts that aren’t see-through). Durable twill fabric is key for uniforms that are washed daily. Look for Herringbone variations for differentiation.

- Suggested Cooperation: Ideal for “Never Out of Stock” (NOOS) programs due to its durability and timeless appeal.

🔍 Sourcing Tips: How to Check Quality for Each

When you receive samples, what defects should you look for?

1. Poplin QC: The “Weaving Bar” Check

Because Poplin is a flat, plain weave, it hides nothing. The most common defect is “Weaving Bars” (horizontal lines caused by uneven tension).

Tip: Hold the poplin dress shirt fabric up to the light. The texture should be perfectly uniform. Any slubs or knots will be immediately visible and are considered defects in formal poplin.

2. Oxford QC: The “Color Consistency” Check

Since Oxford is yarn-dyed, color consistency between batches is the biggest risk.

Tip: Check for “striping” or uneven color mixing. Ensure the white weft yarn is clean and not stained by the colored warp.

3. Twill QC: The “Skewing” Check

Twill fabric has natural internal tension due to the diagonal weave. It wants to twist.

Tip: Check the “Spirality” or Skewing. After washing, the side seam of a twill shirt can twist to the front. Ensure the factory has “Sanforized” and skewed-set the fabric.

🏁 Conclusion

In the battle of Poplin vs Oxford vs Twill, there is no single winner.

- Choose Poplin if you want a crisp, formal, breathable shirt for suits.

- Choose Oxford if you want a durable, textured, versatile shirt for business casual.

- Choose Twill if you want a soft, opaque, drape-heavy shirt that resists wrinkles.

As a buyer, your job is to align the fabric’s DNA with your customer’s expectations.

Don’t put a heavy Oxford in a summer collection, and don’t use a sheer Poplin for a winter uniform.

Ready to source your next shirt collection?

We produce all three weaves in-house, from 40s standard to 120s luxury grades. contact-us today to request our “Shirt Fabric Master Kit” containing swatches of Poplin, Oxford, and Twill for immediate comparison.

❓Frequently Asked Questions

Is a poplin shirt great quality?

Yes, but “quality” depends on the yarn count and finish. A cheap 40s carded poplin can feel paper-like. A luxury 100s two-ply mercerized poplin feels like silk. Poplin is the standard for high-quality formalwear.

Which is better, Oxford vs Twill?

For durability and casual style, Oxford is better. For softness, drape, and formality, Twill is better. A twillory shirt (a brand famous for non-iron) often uses twill because it holds the non-iron chemical finish better than the open weave of an Oxford.

What is dress shirt texture?

Dress shirt texture refers to the surface feel and visual pattern created by the weave. Poplin has no texture (smooth). Oxford has a “dot” or “basket” texture. Twill has a diagonal line texture. Herringbone has a zigzag texture.

Is Oxford vs Poplin shirt cooler for summer?

Poplin is generally cooler. Its fine yarns and single-layer weave allow maximum heat to escape. While Oxford is breathable due to its porous weave, the fabric itself is thicker and heavier, making it warmer than Poplin.

Does Oxford cloth wrinkle easily?

Standard Oxford cloth resists wrinkles better than Poplin because the fabric is heavier and the basket weave is more relaxed. However, Twill is the most wrinkle-resistant of the three.

What is royal oxford fabric?

Royal Oxford is a variation of the Oxford weave that uses finer yarns and a more complex weaving pattern. It results in a fabric that is much shinier, softer, and more textured than standard Oxford cloth, making it suitable for formal occasions.