🧵 Introduction: The Most Common Fabric, The Most Common Mistakes

Poplin is the “white bread” of the shirting world—it is the most fundamental, versatile, and essential fabric in any collection. Yet, precisely because it is so common, it is also the fabric where buyers make the most frequent and costly mistakes.

⚠️ The Cost of Cutting Corners

I’ve seen it happen countless times: a buyer pushes for a lower price, the factory swaps the density from 133×72 to 110×70, and the final shirts arrive looking thin, cheap, and prone to seam slippage. Or, a brand orders a “standard soft finish” for a dress shirt, only to find it lacks the crisp, professional hand-feel their customers expect.

This Sourcing Poplin Fabric Guide: Specs, Cost & Quality is designed to stop those mistakes before they happen. As a textile manufacturer, I’ll walk you through poplin sourcing from the factory floor: we’ll decode the “Poplin Code” of yarn counts and density, analyze the cost implications of CVC vs TC vs cotton, and explain why advanced finishes like liquid ammonia are worth the investment.

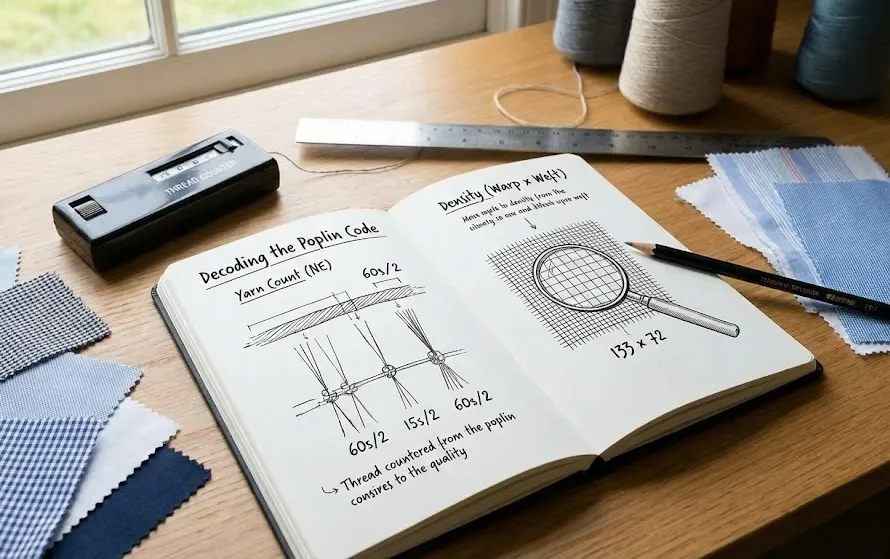

🔢 Consideration #1: Decoding the “Poplin Code” (Yarn Count & Density)

When you look at a supplier’s swatch card, you’ll see a string of numbers like “40s x 40s / 133 x 72”. This isn’t just technical jargon; it’s the DNA of the fabric’s quality and cost. Understanding this code is the single most important skill in poplin fabric wholesale sourcing.

🏆 The Golden Standard: 40s x 40s / 133 x 72

This specific specification—40s cotton poplin with a density of 133×72—is the global benchmark for a quality, mid-range dress shirt.

- 40s x 40s: Refers to the yarn count (thickness) of the warp and weft.

- 133 x 72: Refers to the density. There are 133 warp threads and 72 weft threads per inch.

🏭 (Factory Experience)

In our factory, “133×72” is the baseline for quality. If a supplier offers you a “40s poplin” at a significantly lower price, check the density. They are likely offering 110×70 or 120×60.

While these are still poplin, the difference in poplin fabric density means the fabric will be more transparent, have a looser structure, and is highly prone to ‘Seam Slippage’ (where the fabric pulls apart at the seams under stress). For a professional shirt, never go below 133×72.

High-End Specs: 60s, 80s, and 2-Ply

When should you upgrade your specs? It depends on your market positioning.

- 50s Poplin Fabric (140×80): A step up from the standard 40s. It feels slightly silkier and is less transparent. Ideal for better department store brands.

- 60s Poplin (140×90 or higher): This is the entry point for true “high-end” business shirts. The yarn is finer, requiring high-quality cotton fibers.

- 80s/2 or 100s/2 (2-Ply Poplin Fabric): This is the luxury tier. “2-Ply” means two ultra-fine yarns are twisted together to make one strong thread. 80s 2 ply poplin has an incredibly smooth, silky hand-feel and superior durability compared to single yarns. It creates a shirt that feels substantial yet breathable.

(For a deeper understanding of these numbers, see our fabric-weight-guide-yarn-count-gsm guide.)

🧬 Consideration #2: Composition Strategy (Cotton vs. Blends)

The fiber composition dictates the price point, wrinkle resistance, and target audience. Here is a breakdown to help you choose.

| Composition | Characteristics | Best For |

|---|---|---|

| 100% Cotton Poplin | Breathable, soft, natural luxury. Prone to wrinkling unless treated. | Mid-to-High End Retail Brands, Luxury Shirting. |

| CVC (Chief Value Cotton) | Typically 60% Cotton / 40% Poly. Better wrinkle resistance than pure cotton, cheaper price. | Corporate Uniforms, School Wear, Mid-Range Retail. |

| TC (Tetoron Cotton) | Typically 65% Poly / 35% Cotton. Extremely durable, no wrinkles, very cheap, but less breathable. | Industrial Workwear, Low-Cost Promotions, Budget Uniforms. |

🔍 Deep Dive

100% Cotton Poplin Fabric Wholesale

This is the standard for fashion. Brands prioritize the hand-feel and breathability. However, you must consider a “Wrinkle-Free” finish to satisfy modern consumers.

CVC Fabric Meaning

CVC stands for “Chief Value Cotton,” meaning cotton makes up more than 50% of the blend. It’s a strategic “middle ground.” You get some of the comfort of cotton with the strength of polyester.

TC Fabric / TC Poplin

This is a volume driver. It is incredibly stable and colorfast. If you are sourcing for a supermarket uniform program where longevity and cost are the only metrics, TC fabric is the correct choice.

(Still deciding on the blend? Read our detailed comparison: cotton-vs-polyester-fabric-expert-comparison)

✋ Consideration #3: The “Hand-Feel” Factor (Finishing Technologies)

This is the secret weapon of shirt fabric manufacturers. You can take the exact same greige (raw) fabric and make it feel like a $5 shirt or a $50 shirt just by changing the finishing process.

1. Regular Soft Finish vs. Silicon Finish

- Regular Soft: A basic mechanical softening. Good for budget items.

- Silicon Finish: Adds a chemical softener that gives the fabric a “slippery,” silky hand-feel. This is standard for most fashion shirts but can reduce absorbency.

2. Mercerization (The High-End Standard)

Mercerized poplin fabric is treated with caustic soda to swell the fibers, making them rounder and smoother.

Why it matters: It increases luster (shine) and color depth. For any 100% cotton poplin fabric wholesale order intended for a premium brand, we highly recommend mercerization. It transforms a matte cotton into something that looks lively and expensive.

3. Liquid Ammonia Finish (The “Ferrari” of Finishes)

If you are looking for the absolute best, ask for a liquid ammonia finish fabric.

- What it is: A chemical treatment that modifies the cotton fiber structure, reducing internal stress.

- The Result: The fabric becomes incredibly soft, smooth, and has a “memory” effect that resists wrinkling naturally. It feels cool to the touch, almost like silk-cotton. This is the secret behind many top-tier “Non-Iron” shirts.

4. Wrinkle-Free / Easy Care

For business shirts, wrinkle free poplin fabric is often a requirement, not an option. This is usually achieved through a resin cross-linking process (often called “Easy Care” or “DP Rating 3.5”). Be aware that heavy resin can reduce tear strength, so it must be balanced carefully.

🕵️♀️ Consideration #4: Quality Control Checkpoints for Poplin

Poplin is unforgiving. Its flat, smooth surface highlights every defect. Here is what our factory QC team looks for, and what you should check.

1. Weaving Bars (Run-Ins/Stop Marks)

Fabric weaving bars are horizontal lines across the width of the fabric caused by the loom stopping and starting or inconsistent tension.

The Check: Hold the fabric up to a light source. The density should be perfectly uniform. Any horizontal bands are a major defect in poplin.

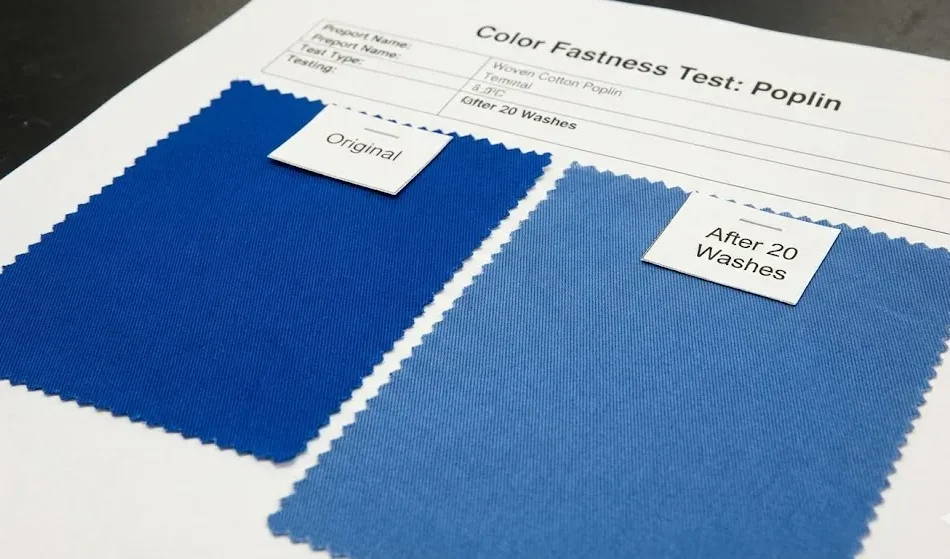

2. Color Fastness (Rubbing)

Poplin, especially in dark colors like Navy or Black, can be prone to “frosting” or white abrasion marks if the dye doesn’t penetrate well.

The Check: We require a Colorfastness to Crocking grade of 3-4 (Wet) and 4 (Dry). Ask your supplier for this test report specifically for dark poplin.

3. Whiteness (For White Shirts)

White is the most popular poplin color, but there are many shades of white.

The Check: Specify if you need “Bleached White” (cool, bluish undertone, achieved with optical brighteners) or “Natural White/Milk White” (warmer, creamy undertone). Confusing these is a common sourcing error.

⏳ Consideration #5: Cost & Lead Time Reality

Understanding the market reality helps you plan your “Critical Path.”

1. Stock Service (Ready Goods)

Many poplin fabric suppliers, including us, keep “running items” in stock.

- Specs: Typically 40s/133×72 and 50s/144×80 in standard colors (White, Blue, Black).

- Pros: Low MOQ (often 1 roll/100m), immediate shipment.

- Cons: Higher unit price, limited to standard specs.

2. Fresh Order (Make-to-Order)

- Specs: Anything you want (e.g., stretch poplin fabric with 3% spandex, or 80s 2 ply).

- Lead Time: Typically 45-60 days. Yarn procurement takes 20 days, weaving 15 days, finishing 10 days.

- MOQ: Usually 3000m per color for custom dyeing.

(For a step-by-step guide on negotiating these terms, please read our strategic-cotton-sourcing-guide.)

📝 Conclusion: How to Build Your Poplin Tech Pack

Sourcing the perfect poplin isn’t about luck; it’s about specification. To get an accurate quote and the right quality, your Tech Pack or inquiry must be precise.

✅ The Perfect Poplin Inquiry Template:

- Fabric: 100% Cotton Poplin (or CVC 60/40)

- Yarn Count: 40s x 40s (or 80s/2 x 80s/2)

- Density: 133 x 72 (Must specify to avoid low-density substitutes)

- Weight: 120 GSM (+/- 5%)

- Finish: Mercerized + Liquid Ammonia (or Regular Soft)

- Color: Pantone 19-4052 TCX

By defining these parameters, you filter out low-end traders and engage directly with professional manufacturers who speak your language.

🚀 Ready to source your next shirt collection?

Whether you need a budget-friendly TC workwear poplin or a luxury Liquid Ammonia 100s/2 cotton fabric, we have the production capability to meet your target price and quality. contact-us today to request our “Poplin Master Card” featuring our full range of weights and finishes.

❓ FAQ (Frequently Asked Questions)

What is the best weight (GSM) for a white poplin shirt?

The standard poplin weight for a high-quality white dress shirt is 115-125 GSM. Anything below 110 GSM will likely be too transparent (see-through) without an undershirt. A poplin fabric gsm of 130+ is considered heavy and very opaque, good for winter or unlined casual shirts.

Is poplin better than twill for summer?

Yes, poplin vs oxford vs twill for summer? Poplin wins. Its plain weave structure creates a thinner, lighter fabric that allows for better airflow compared to the denser diagonal weave of twill or the heavier basket weave of Oxford. It is the definitive summer shirting choice.

Can I print on poplin?

Yes, absolutely. Because poplin has a flat, smooth surface (no texture like Oxford or ridges like Twill), it is the ideal base for printing. It allows for extremely fine detail and sharp lines, making it perfect for intricate digital or screen prints.