🔬 Expert Guide: Averting Colorfastness Disasters in Fabric QC

A 20-Year QC Lead’s Most Regrettable Lesson

As a technical lead with 20 years of fabric QC experience, I’ve witnessed the most regrettable losses: brands spending heavily on custom cotton fabrics dyed with reactive dyes, where bulk production perfectly matched swatches and passed washfastness tests—yet faced widespread complaints of sweat-induced fading in tropical end markets due to heavy perspiration, severely damaging brand credibility. The root cause lies not in the colorfastness tests themselves, but in mismatched dye types and testing standards.

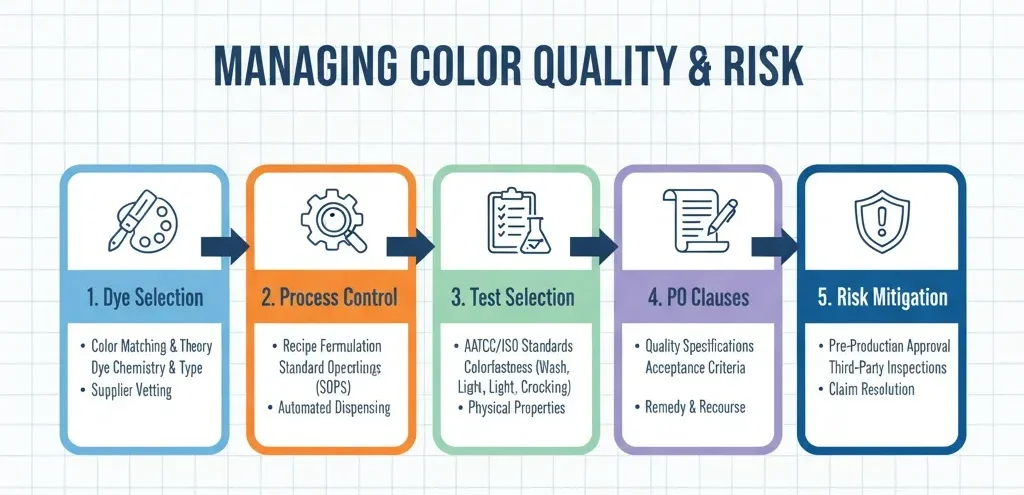

This article not only decodes AATCC/ISO test codes but also guides you through the entire chain: dye selection → process control → test selection → PO clauses → risk mitigation.

Trust me, after thoroughly reading this article, you will learn:

- How to select test items based on dye type?

- How to adjust testing standards for target markets?

- How to leverage test data to drive supplier process optimization?

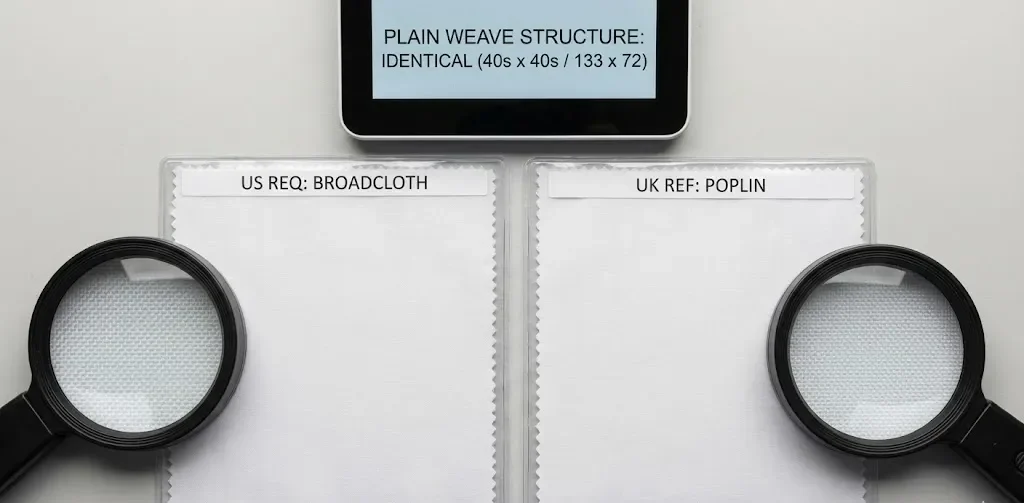

The upper limit of colorfastness is determined by dyeing processes and dyes. First understand the differences between reactive, vat, and direct dyes—then testing becomes truly meaningful: cotton-dyeing-methods-reactive-vat-pigment

🎨 What is Colorfastness? (A Core Definition)

So, what is colorfastness in textiles? The simplest colorfastness meaning is a fabric’s ability to resist fading (losing its own color) and bleeding/staining (transferring its color onto other materials). It measures how well a dye is “locked” onto a fiber when challenged by external conditions.

⚖️ How is it Graded? (The Gray Scale System)

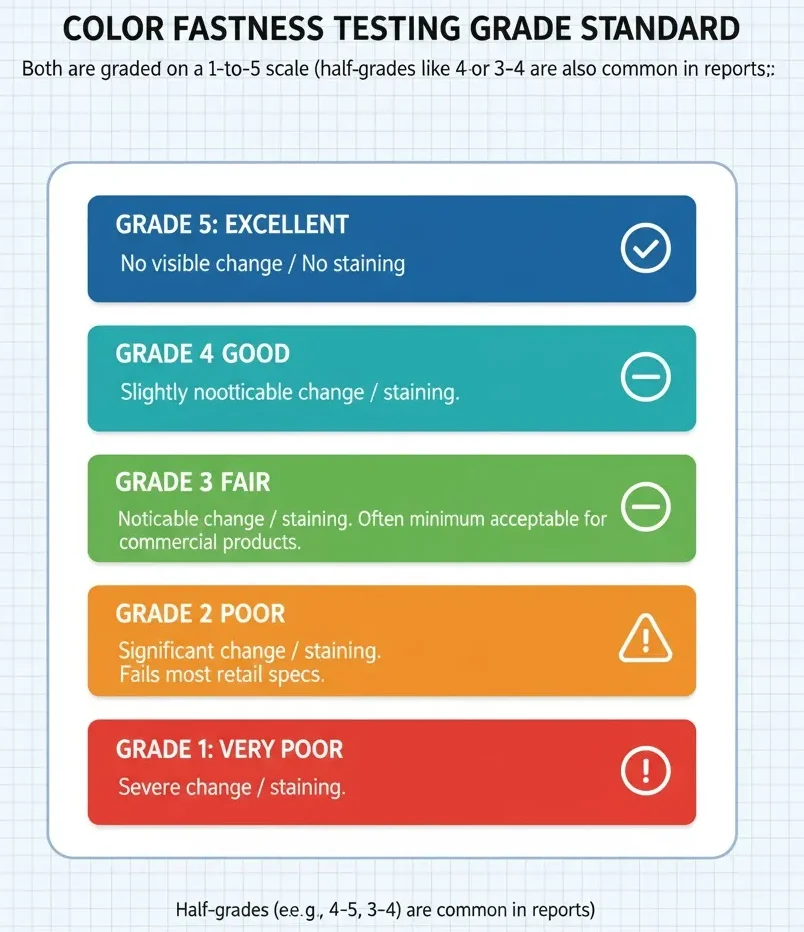

We don’t use subjective words like good or bad. Quality is measured. We use a standardized Gray Scale to assess two separate things:

- Color Change: How much the original fabric has faded.

- Staining: How much the dye has bled onto an adjacent undyed fabric.

Both are graded on a 1-to-5 scale (half-grades like 4–5 or 3–4 are also common in reports):

- Grade 5: Excellent (no visible change / no staining)

- Grade 4: Good

- Grade 3: Fair (often the minimum acceptable for commercial products)

- Grade 2: Poor (noticeable fading or staining; fails most retail specs)

- Grade 1: Very Poor (severe fading / severe staining)

Buyer takeaway: In a PO, always specify the test method + grade (e.g., AATCC 61, Grade ≥4.0 (CC/CS)). “Grade 4 or higher” is typical for mid-to-high-end brands. Babywear often targets Grade 4.5 on relevant tests.

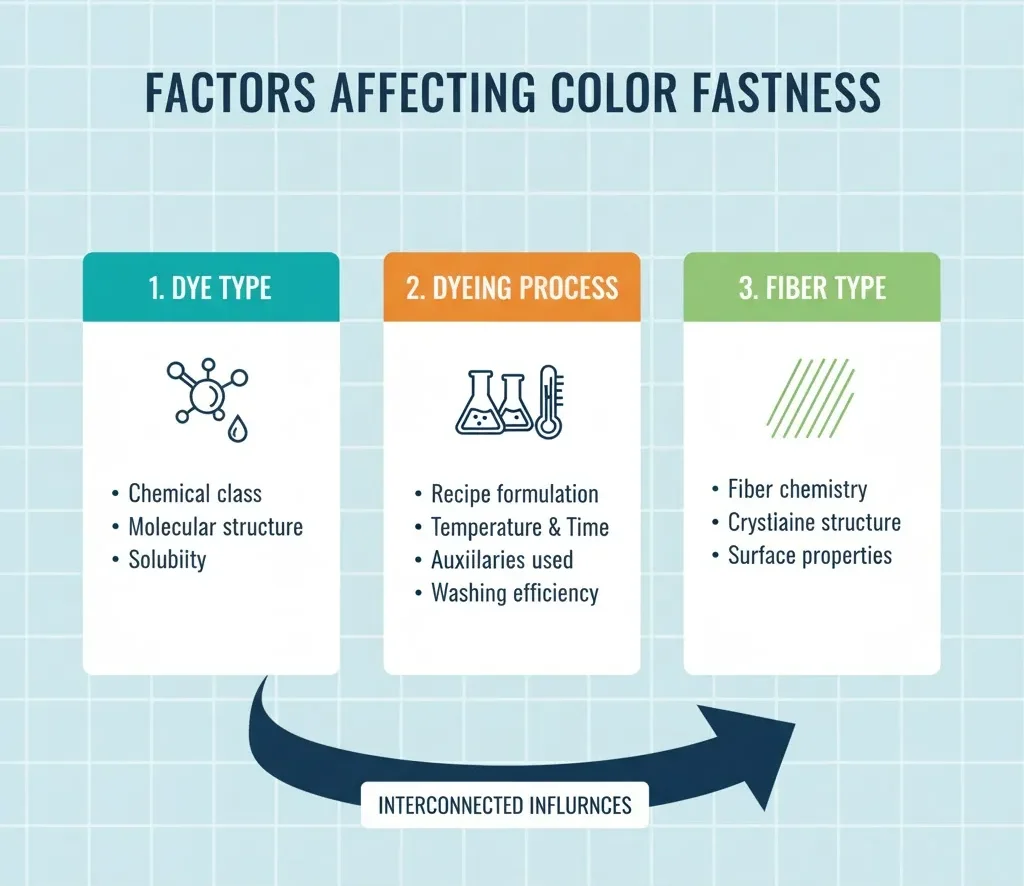

⚙️ What Factors Influence the Final Grade?

The final grade isn’t arbitrary—it’s a direct result of manufacturing choices.

- Dye Type: Reactive and vat dyes bond strongly to cotton and generally give higher fastness. Cheaper direct dyes (now largely excluded from responsible supply chains due to safety concerns) have poor fastness.

- Dyeing Process: Parameters such as temperature, time, alkali/salt levels, oxidation/soaping, and after-washing determine how completely the dye fixes.

- Fiber Type: Cotton vs. polyester vs. silk have different dye affinities; method and recipe must match the fiber.

Factory Tips: It’s a common misconception that “color fastness” vs “dye fastness” are different. They’re the same concept in textile testing.

📜 Standards Cheat-Sheet: AATCC vs ISO vs JIS

- AATCC (American Association of Textile Chemists and Colorists):US-based test methods (e.g., AATCC 61 washing, AATCC 8 crocking, AATCC 16 light). Widely used in North America.

- ISO (International Organization for Standardization):Global standards, especially common in the EU and international programs (e.g., ISO 105 series for washing/crocking/light). Default for multi-country export.

- JIS (Japanese Industrial Standards):Japan’s national test methods for textiles (e.g., JIS L series). Use when exporting to Japan or when a buyer explicitly requires JIS.

Spec tip: Choose one standard family per PO/tech pack (AATCC or ISO or JIS) to avoid disputes and mismatched test procedures.

🧪 The 7 Types of Colorfastness Every Buyer Must Know

Colorfastness is not one test; it’s a matrix of different performance scenarios. You must specify the types of fastness relevant to your product.

1. Colorfastness to Washing

What is it for?

Simulates a lifetime of consumer home laundering to see if a fabric fades or stains other clothes in the wash.

Standard Numbers:

AATCC 61 (North America) / ISO 105-C06 (International)

What it tests:

Measures both Color Change (fading) and Staining (bleeding) using a standard multi-fiber strip in a heated, agitated bath with detergent and steel balls.

Dye Matching:

Reactive dyes are excellent, which is how to improve washing fastness in reactive dyeing (the key is the process). Vat dyes are also excellent. Pigment dyes are generally fair to poor.

Procurement Decision:

This is the most fundamental test, mandatory for almost all apparel. For hotel linens requiring high-temp washes, you must specify a more aggressive test (e.g., ISO 105-C06 A2S at 60°C).

2. Colorfastness to Crocking (Rubbing)

What is it for?

Simulates color transfer from rubbing, either dry (like a blue jean on a white sofa) or wet (like a damp red shirt rubbing against a white bag).

Standard Numbers:

AATCC 8 (North America) / ISO 105-X12 (International)

What it tests:

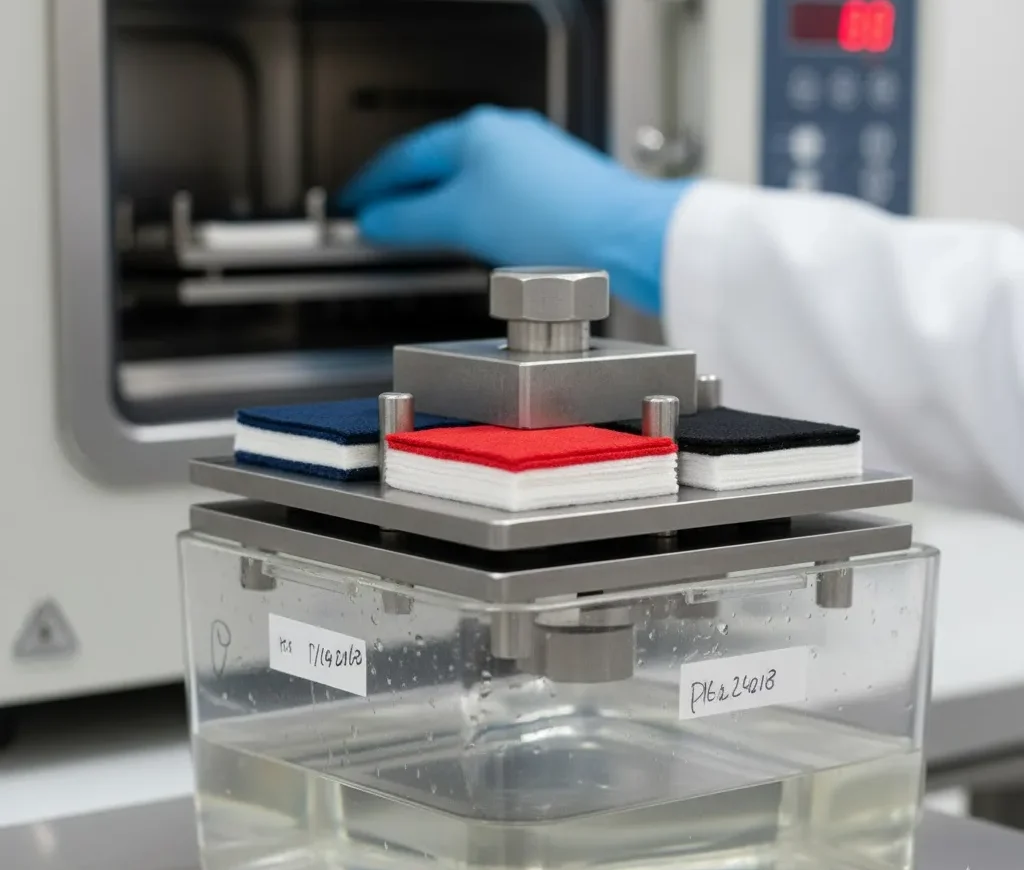

A standard white cotton cloth (a crock square) is rubbed against the fabric’s surface with a specified pressure. The amount of color transferred to the white cloth is then graded. This gives two separate grades: Dry Crockford and Wet Crockford.

Dye Matching:

This is a major challenge for pigment dyeing (where color is on the surface) and indigo vat dyeing for denim (where dye is designed to rub off).

Procurement Decision:

This is a critical pass/fail test. For dark colors, especially on items like denim or upholstery, you must specify an acceptable wet crocking grade (e.g., Wet Crockford: Grade 2.5-3.0 minimum). A low grade here leads to massive customer complaints.

3. Colorfastness to Light

What is it for?

Simulates exposure to sunlight (UV) to see if a fabric will fade over time.

Standard Numbers:

AATCC 16 (North America) / ISO 105-B02 (International)

What it tests:

Fabric samples are exposed to a high-intensity xenon arc lamp (which mimics natural sunlight) for a specific duration (e.g., 20 or 40 “AFU” – AATCC Fading Units). The fading is then compared to a standard blue wool scale.

Dye Matching:

Vat dyes are known for having the best fastness to light.

Procurement Decision:

This is a mandatory test for home textiles curtains and upholstery, outdoor garments, and swimwear. For indoor use, a Grade 4 is often sufficient. For outdoor use, Grade 5 or higher is required.

Industry Case Study:The choice of dye and finish has a direct, measurable impact. A case study from the International Textile and Apparel Association (ITAA), for example, explored how new dyeing processes (like dope dyeing) dramatically improved both colorfastness to washing (AATCC 61) and colorfastness to light (AATCC 16) results compared to traditional methods. This research, available via repositories like the Iowa State Digital Press, confirms that specifying a high grade is useless if the supplier isn’t using a process capable of achieving it. It validates the link between process selection and performance outcomes.

4. Colorfastness to Perspiration

What is it for?

Simulates the effect of human sweat on dye, which can be acidic or alkaline. This was the exact test missed in my opening story.

Standard Numbers:

AATCC 15 / ISO 105-E04

What it tests:

The fabric is soaked in two different chemical solutions (one acidic, one alkaline) and pressed against a multi-fiber strip under pressure and heat for several hours.

Dye Matching:

Reactive dyes have an inherent advantage due to their stable covalent bond, which is resistant to the pH changes in sweat.

Procurement Decision:

This is mandatory for sportswear, polos, underwear, and any performance or summer apparel. You must specify and pass both the acidic and alkaline tests.

Technical White Paper:Why do reactive dyes perform better here?

The chemical bond they form with cotton’s cellulose is stable against pH changes. Direct dyes, which rely on weaker bonds, can be broken down by the acids or salts in sweat, causing color to bleed. As technical bulletins from experts like Cotton Incorporated explain, the key is not just the dye, but the thorough soaping wash after dyeing to remove all unfixed dye particles. This is why we prioritize reactive dyeing for all high-performance, next-to-skin cotton garments.

5. Colorfastness to Dry Cleaning

What is it for?

Tests how a fabric reacts to standard dry-cleaning solvents (like perchloroethylene).

Standard Numbers:

AATCC 132 / ISO 105-D01

Procurement Decision:

Only necessary for high-end, “Dry Clean Only” garments like tailored suits, blazers, or delicate home furnishings.

6. Colorfastness to Chlorine Bleach

What is it for?

Tests a fabric’s ability to withstand household or industrial chlorine bleach.

Standard Numbers:

AATCC 61 (Procedure 5A) / ISO 105-N01

Dye Matching:

Only vat dyes are specifically engineered to offer high chlorine resistance. Reactive dyes will be stripped of their color.

Procurement Decision:

This is a critical, non-negotiable test for colorfastness standards for hotel sheets and towels and medical textiles, which must be sanitized with bleach.

7. Colorfastness to Ironing

What is it for?

Tests if the color will change, fade, or transfer to the iron or an adjacent fabric when subjected to hot pressing.

Standard Numbers:

AATCC 133 / ISO 105-X11

Procurement Decision:

A standard check for most apparel, especially shirting. It ensures the garment can be properly finished and cared for by the consumer.

✍️ Sourcing Guide: How to Use This Knowledge in Your PO & Tech Pack

Knowing the tests is only half the battle. You must use this knowledge to protect your brand in your technical documents.

Why does this precision matter at scale?

The 2025 Textile Exchange Materials Market Report shows global fiber production at nearly 124 million tonnes, with cotton as a primary natural fiber. In such a massive market, specifying your performance requirements is the only way to ensure quality consistency and manage the huge financial risks associated with returns, rejections, and brand damage from a bad batch of fabric.

📋 The Buyer’s Tech Pack Checklist 2.0

Your tech pack should include a colorfastness PO wording template. Do not write good colorfastness. Be precise.

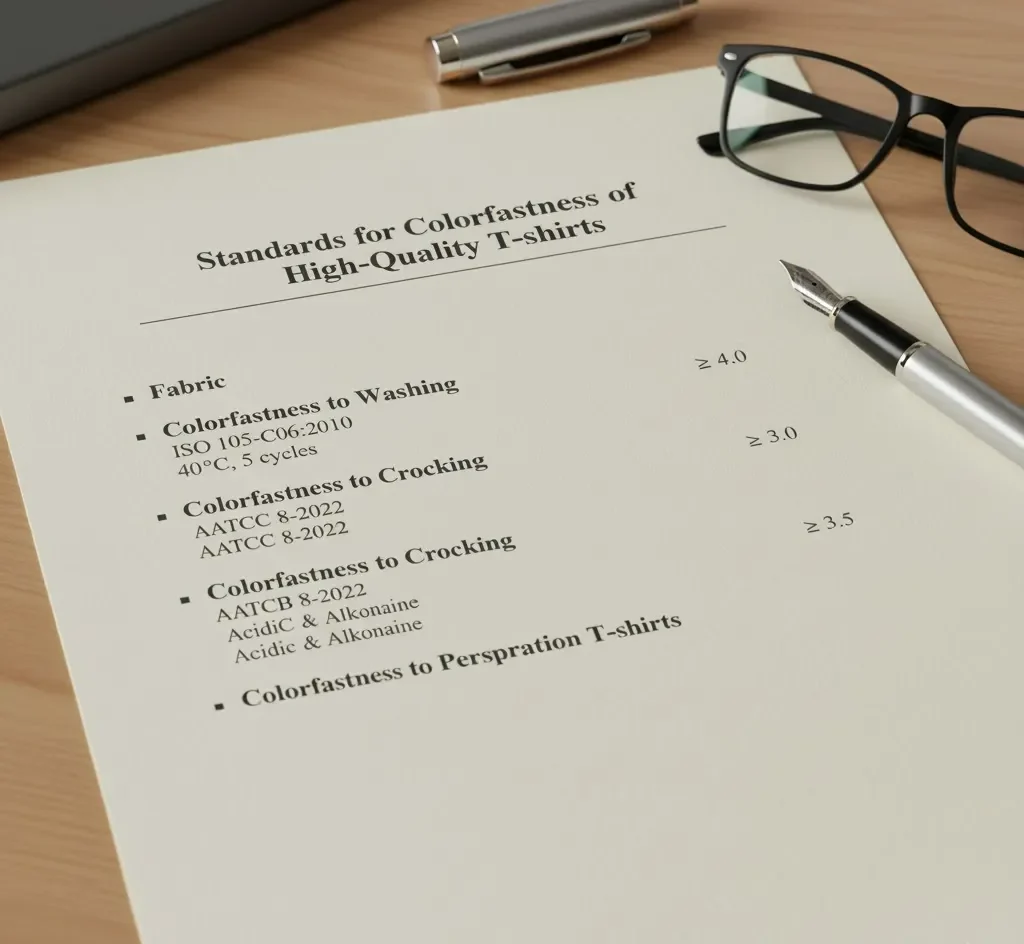

Example Clause for a Premium T-Shirt:

- Fabric must be dyed with 100% Reactive Dyes (GOTS approved).

- Colorfastness to Washing (ISO 105-C06:2010, A2S at 40°C, 5 cycles): Color Change ≥ 4.0, Staining ≥ 4.0.

- Colorfastness to Crocking (AATCC 8-2022): Dry ≥ 4.0, Wet ≥ 3.5.

- Colorfastness to Perspiration (AATCC 15-2023, Acidic & Alkaline): Color Change ≥ 4.0, Staining ≥ 4.0.

Note:Always specify that test samples must be from the bulk production lot, not a small, perfect lab sample.

❌ Common Sourcing Mistakes & How to Avoid Them

Mistake 1: Incomplete Testing. (As in my introduction) You only test for washing but your product fails from sweat.

Solution: Use the “Common Uses” section of this guide to create a test plan based on your product’s actual life cycle.

Mistake 2: Mismatched Standards & Dyes. Asking for a Grade 4 wash fastness on a cheap, direct-dyed fabric.

Solution: Ask the supplier for the dye type first, then set realistic standards.

Mistake 3: Vague Test Conditions. Only writing “Grade 4” without specifying the test method (e.g., AATCC 61 or ISO 105-C06).

Solution: Always specify the full standard, including the year and specific procedure.

Mistake 4: No Pre-Production Testing.

Solution: Make passing a third-party test report (from SGS or Intertek) a condition of approving bulk production.

(These tips are a core part of our strategic-cotton-sourcing-guide.)

🌍 AATCC vs ISO: Which Standard Should You Choose?

This is a common question from buyers.

The Core Difference:AATCC (American Association of Textile Chemists and Colorists) is the primary standard used in North America. ISO (International Organization for Standardization) is used by the rest of the world, including Europe and most of Asia. The AATCC vs ISO colorfastness standards test for the same properties (wash, rub, light), but their procedures, equipment, and test parameters (like temperature, duration, and wash cycle specifics) can differ slightly.

The Sourcing Logic

- Target Market: If you are selling primarily to the USA, specify AATCC. For Europe or global distribution, specify ISO.

- Supplier Capability: Ask your supplier which standard their in-house lab is calibrated to test for.

The Critical Rule

Never mix standards in one PO. Be consistent. Choose one system and stick to it.

Buyer Tip: Navigating the nuanced differences between, for example, AATCC 61 vs ISO 105-C06 can be complex. We recommend reviewing the detailed comparison guides published by third-party testing labs like SGS or on the AATCC.org website itself before finalizing your tech pack.

🏁 Conclusion: Quality is Measured, Not Guessed

Colorfastness is not a single attribute; it’s a multi-dimensional performance matrix. It is the measurable result of correct dye selection, precise process control, and rigorous testing. As your technical partner, our job is to help you navigate this matrix, specify the correct standards in your PO, and deliver a fabric that is safe, beautiful, and durable.

Don’t let a preventable issue like poor abrasion resistance or fastness to perspiration ruin your product launch.

(Ready to develop a fabric with guaranteed color performance? contact us and let our QC experts review your tech pack and recommend the correct testing plan.)

(Explore our finished fabrics, all of which pass rigorous testing, at our cotton fabrics page.)

❓ FAQ (Frequently Asked Questions)

What is a good colorfastness grade?

In the 1-5 grading system, Grade 4.0 is widely considered the standard for high-quality apparel and home textiles, indicating very minimal fading or bleeding. Grade 3.0 is often the minimum acceptable passing grade for challenging items, like the wet crocking on dark-wash denim. Grade 5 is the best and very rare.

Are AATCC and ISO grades interchangeable?

No. While both systems use the same 1-5 gray scale for evaluation, the test methods themselves are different. For example, AATCC 61 and ISO 105-C06 use different temperatures, container sizes, and agitation methods. A Grade 4 under one standard does not automatically equal a Grade 4 under the other. You must specify one.

Why is my t-shirt fading after washing?

This could be due to several reasons: 1) The fabric was dyed with pigment dyeing, which is designed to fade gently for a vintage look. 2) It was dyed with cheap, low-quality dyes (like direct dyes) that have poor wash fastness. 3. It was dyed with reactive dyes, but the factory’s soaping process was poor, leaving unfixed dye on the surface.

(For proper care to minimize fading, see our how to wash pure cotton guide.)

Why does my denim bleed so much (poor crocking fastness)?

This is a known characteristic of indigo, a type of vat dye used for denim. The dye is designed to sit on the surface of the yarn (“ring-dyeing”) so it can fade. This means it has naturally poor colorfastness to crocking (rubbing). While good manufacturing can reduce it, some bleeding, especially when wet, is an expected feature.

(Learn more in our what is denim fabric.)

Which colorfastness tests are mandatory for babywear?

For baby clothing, safety and quality standards are extremely high. Beyond the standard tests for washing (AATCC 61) and crocking (AATCC 8), you must also test for Colorfastness to Perspiration (AATCC 15) and Colorfastness to Saliva (e.g., DIN 53160-1). All components must also comply with chemical safety standards like OEKO-TEX® STANDARD 100, Class 1.