🧣 Introduction

When you think of winter, you likely imagine the comforting touch of a flannel shirt or the cozy embrace of flannel sheets. That signature fuzzy texture—instantly warm against the skin—is irreplaceable.

But for those new to the textile industry: what is flannel fabric exactly? Is it a specific fiber? A pattern? Or something else entirely?

As a fabric manufacturer, I often see confusion surrounding this material: The biggest myth is equating “flannel” with “plaid.”

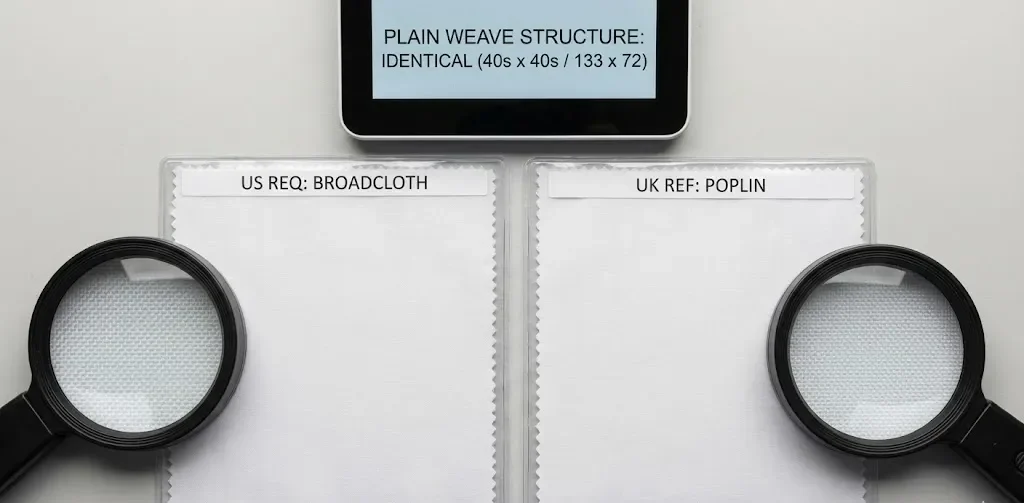

Let’s be clear from the start: Flannel is a fabric defined by its finish; Plaid is just a pattern. You can have a solid white flannel, and you can have a plaid poplin that isn’t flannel at all.

This guide goes beyond the basics. We will unpack the technical reality of flannel—from the mechanical brushing process that creates its famous “nap” to the critical sourcing decisions that determine whether your fabric pills after one wash or lasts for years.Whether you are an independent brand or a large-scale garment factory, this is your definitive guide to understanding, sourcing, and caring for flannel.

🧶 What is Flannel Fabric?

Flannel is a soft, medium-weight woven fabric, typically made from cotton, wool, or synthetic fibers.

Its defining characteristic is the nap on one or both sides. This nap is not a separate pile like velvet; it is created by brushing the base fabric to raise the fine fibers from the yarn itself.

🍎 The Apple vs. 🍑 Peach Analogy

You can think of it as the difference between an apple and a peach. If poplin is a smooth apple, then flannel is a fuzzy peach.

That fuzzy layer (the nap) does two things: it makes the fabric feel incredibly soft against the skin, and it traps stagnant air, creating a natural thermal insulation layer that keeps you warm.

🧵 Is Flannel Woven or Knit?

While you can find knit flannel, But traditional and authentic flannel is a woven fabric. It can be constructed using a Plain Weave or a Twill Weave.

- Plain Weave: Often used for lighter-weight flannels (like baby flannel fabric).

- Twill Weave: Used for heavier, more durable flannels.

🏭 How Is Flannel Made? The Art of Brushing

The secret to how is flannel made lies in the mechanical finishing process known as napping or brushing.

In our factory, we describe this process as “combing the fabric’s hair.” We use a specialized flannel brushing machine equipped with rotating wire-covered rollers. These rollers gently tease the fiber ends out of the yarn body, creating the soft fuzz.

Single-Sided vs Double-Sided Flannel

- Single-Sided (Napped on one side): The nap is usually on the “face” side, while the back remains smooth. This is common for shirts where you want the look of flannel but perhaps a smoother feel against a base layer, or simply to reduce bulk.

- Double-Sided (Napped on both sides): Common in flannel sheets and high-end pajamas. This offers maximum warmth and softness, as the fuzzy texture is against the skin and facing out. Single sided vs double sided flannel is a key specification in your tech pack.

⚙️ Process Expertise: Controlling the Nap

On our brushing range, nap height is strictly controlled by line speed, roller pressure, and pass count.

- For single sided flannel (typically for shirts), we brush the face and then shear it to level the pile for a neat appearance.

- For double sided flannel (like bedding), we must carefully balance the face and back nap to avoid a “grabby” hand that causes friction.

While heavy napping hides the weave and boosts warmth, we dial it back when durability is critical, because aggressive napping vs raising can reduce the fabric’s abrasion strength. These trade-offs are exactly what the technical literature describes for napping/raising finishes.

⚖️ The Pros and Cons of Flannel Fabric

Is flannel the right choice for your collection? Let’s weigh the advantages of flannel fabric list against its limitations.

✅ Pros

- Exceptional Warmth: Cotton flannel is breathable but highly insulating due to the trapped air in the nap.

- Soft Hand-Feel: It is arguably the softest woven cotton fabric available.

- Absorbency: Like all cotton, it wicks moisture, making it comfortable for sleepwear.

📊 (Our In-House Lab Data)

We don’t just claim it’s good; we measure it. Here is our flannel pilling & handle test data (Cotton flannel, 170–200 GSM, twill):

- Pilling Resistance: Baseline samples often score Grade 2.5–3.0 on the Random Tumble Pilling test (ASTM D3512). After applying our proprietary anti-pilling finish, the score improves to Grade 3.5–4.0, an average 30-40% visual improvement.

- Durability: In the ISO 12945-1 Pilling Box test, the number of cycles to reach Grade 3 increased by +25-35% after we optimized our brushing and shearing sequence to remove weak surface fibers.

- Thermal Comfort: Our “Warmth vs. Weight” shop-floor trials confirmed that double-sided nap is consistently perceived as warmer at the same GSM compared to single-sided, validating the air-trapping effect.

Note: We run both ASTM and ISO methods for buyer reports so your QC team can compare apples to apples.

⚠️ Cons

- Pilling: The raised fibers are prone to tangling into pills. Disadvantages of flannel pilling are the consumer complaint.

- Shrinkage: The mechanical action of brushing relaxes the yarns, making flannel shrinkage a significant issue if not pre-shrunk.

- Slow Drying: The fuzzy surface holds onto water, making it heavier when wet and slower to dry than smooth cotton.

🧵 The Main Types of Flannel Fabric

Cotton Flannel (Canton Flannel)

This is the most commercially common type, woven from 100% cotton. It is known for its high absorbency, breathability, and the ability to be napped on one or both sides for varying degrees of warmth.

Wool Flannel

The original and most premium version, made from carded wool yarns. It offers superior thermal insulation even when wet and has a natural resilience that makes it the standard for high-end tailoring and suits.

Synthetic / Micro-Flannel

Typically made from 100% polyester microfibers. It is incredibly lightweight, hydrophobic (quick-drying), and resists pilling better than cotton, making it ideal for budget-friendly blankets and sleepwear.

Baby Flannel

A specialized, ultra-lightweight cotton or cotton/wool blend that undergoes double-brushing. It is engineered to be hypoallergenic and non-irritating, specifically for sensitive infant skin applications like swaddles.

Ceylon Flannel

A historical blend of 50% cotton and 50% wool. It combines the soft, non-itchy feel of cotton with the superior warmth retention of wool, offering a balanced premium fabric.

📊 Customer Case:European home-textile brand (double-sided micro-flannel sheets)

Their pain points were early pilling and a draggy hand.

- Solution: We switched the base weave to a denser twill, reduced each-side nap height by ~10%, added a low-add-on anti-pilling finish, then re-sheared.

- Result: Complaint rate on pilling dropped 58% season-over-season; hand feel scored +0.8 on their internal scale; returns fell below 1%.

This aligns with reference texts noting twill’s durability and the role of controlled raising/shearing in premium flannel.

🏭 The Uses of Flannel: A B2B Application Guide

Flannel is versatile, but different sectors use it for very different products. Here is how to match the fabric to your business model.

🎨 For Independent Fashion Brands (Design Focus)

For brands focusing on streetwear or heritage aesthetics, flannel is a storytelling tool. It is the perfect material for designing (Shirt-Jackets) and limited-edition winter drops.

Brands often use heavyweight (250+ GSM) plaids to create structured, layered looks that convey a rugged, outdoor lifestyle image.

🏗️ For Garment Factories (Production Focus)

For large-scale apparel manufacturing, flannel is the workhorse for Autumn/Winter collections.

- Business Casual: Solid-color, high-yarn-count cotton flannels are used to produce softer alternatives to crisp poplin shirts for office wear.

- Outerwear Linings: Factories frequently use lighter flannel as a lining for denim jackets or canvas coats to add thermal value without bulk.

- Loungewear: It is the standard fabric for producing high-volume pajama sets and plaid lounge pants due to its comfort profile.

🛏️ For Home Textile Manufacturers (Bedding Focus)

In the home textile sector, flannel is a seasonal staple.

- Bedding Sets: Manufacturers use wide-width, double-napped cotton flannel to produce flannel sheets, duvet covers, and pillowcases that target cold-climate markets.

- Throws & Blankets: Synthetic micro-flannel is widely used here for its cost-effectiveness and plush hand-feel, creating high-margin impulse buy items.

🌏 Where to Buy Flannel Fabric? (B2B Sourcing Channels)

Finding a reliable flannel fabric supplier is not just about location; it’s about choosing the right channel that matches your order volume and customization needs. Here are the three primary ways professional buyers source flannel.

🎟️ 1. Industry Trade Shows (Best for Physical Evaluation)

For flannel, touch is everything. Trade shows like Intertextile (Shanghai), Première Vision (Paris), or Texworld (NYC/Paris) are the best places to evaluate the “hand-feel” and nap quality instantly.

Strategy: Look for mills that display a wide range of yarn-dyed plaids and brushed solids. Ask to feel their “double-brushed” vs. “single-brushed” samples side-by-side.

🔍 2. Direct Online Search (Best for Targeted Mill Partnerships)

Using search engines to find “flannel fabric manufacturers” or “brushed cotton fabric mills” often leads you directly to factory websites.

Strategy: Look for suppliers who explicitly list their brushing equipment and capacity. A professional mill will showcase their OEKO-TEX certificates and provide detailed specs on their brushing process. This path is ideal for brands seeking long-term development partners.

🌐 3. Alibaba & B2B Platforms (Best for Efficiency)

Alibaba is a massive resource for finding wholesale flannel fabric.

Strategy: When searching, filter for Verified Suppliers with at least 3+ years of history. Pay close attention to their transaction history for “Winter Fabrics.”

⚠️ Warning: Be careful with ready goods (stock). Always ask: “Is this fresh production or leftover stock?” Fresh production ensures better strength, as stock flannel can become brittle over time.

🔍 Sourcing & Quality: How to Spot “Good” Flannel? (B2B Perspective)

How do you ensure you aren’t buying a low-quality product that will pill immediately? Use this checklist.

1. Look at the Weave (Twill is King)

Is flannel twill or plain weave which is better? For durability and density, Twill is generally better. It allows for a tighter construction that holds the nap better and resists abrasion.

fabric-weave-types-explained details why twill is the “heavy duty” choice.

2. Check the Weight (GSM)

Specifying the right weight is crucial for the end-use.

- Shirts: 170–190 gsm.

- Jackets/Overshirts: 250–300 gsm.

- Sheets: 150-170 gsm.

(Learn how to calculate and check these weights in our fabric-weight-guide-yarn-count-gsm guide.)

3. The “Pilling” Test

Never buy flannel without asking for a pilling test report. Ask: “Is this anti pilling finish for flannel applied?”

✅ (Standards-Backed Checklist)

For professional buyers, here is the checklist we ask our own QC team to verify on every lot:

- Weave & GSM fit-for-use: Confirm the spec matches the product (e.g., shirts 150–200 GSM; outer 250+).

- Pilling Reports: Demand ASTM D3512 (Random Tumble) or ISO 12945 (Martindale) reports. Look for clear grades (e.g., Grade 3-4) & cycle counts.

- Brushing/Shearing Recipe: Ask for details on passes and face/back balance. Note that a “heavy” nap can sometimes mask a loose, cheap weave—be careful.

- Single vs. Double-Sided: Verify the hand-feel target and request “wash-down” photos to see how the nap looks after laundering.

📦 How to Store Bulk Flannel Rolls

Storage is critical to maintaining the fluff.

⚠️ Risk: Crushed Nap

If flannel rolls are stacked too high or compressed, the nap can be permanently crushed, ruining the hand-feel.

✅ Operational Best Practices

Horizontal vs vertical roll storage flannel?

Horizontal on racks (not stacked on each other) is best.

Moisture:

Flannel storage humidity control is vital. The fuzzy surface absorbs moisture easily, leading to mildew.

(For a complete warehouse SOP, see our guide on how-to-store-bulk-denim-b2b-guide (The anti-mold principles apply to all cottons).)

🏁 Conclusion

Flannel is more than just a cozy fabric; it is a feat of textile engineering. From the selection of the weave to the precision of the wire rollers in the brushing machine, every step defines its quality. Knowing what is flannel fabric, knowing your GSM requirements, and demanding rigorous pilling tests, you can source flannel that delights your customers season after season.

Ready to develop your next winter collection? contact-us to request our premium flannel swatch book.

❓ FAQ (Frequently Asked Questions)

Will flannel shrink?

Yes, does flannel shrink is a definite yes. Because the yarns are relaxed during brushing, it can shrink significantly. Always source Sanforized (pre-shrunk) flannel or account for shrinkage in your pattern.

(See how-to-wash-pure-cotton for care tips.)

Does flannel fabric fray?

Yes, woven flannel frays when cut. It is not a felt. Seams must be finished (serged/overlocked).

How to bleach flannel shirts?

Be careful. Bleach can damage the fine fibers of the nap. If you must, use a diluted solution or, better yet, use discharge printing for design effects.

Are flannels business casual?

Solid color, high-quality cotton or wool flannels can be business casual. Large plaids are generally considered casual wear.

Single sided vs double sided flannel which is warmer?

Double-sided is warmer because it has two layers of “dead air” insulation trapped by the fuzz on both the inside and outside.