✨ Introduction

Have you ever noticed that some 100% cotton t-shirts look faded and fuzzy after just a few washes, while others—like high-end polo shirts or luxury dress shirts—retain a silky shine and vibrant color for years? The secret isn’t necessarily a different plant; it lies in a transformative finishing process with over 170 years of history: mercerization.

For many consumers and even some junior buyers, mercerized cotton is a term often seen on labels but rarely understood. Is it synthetic? Is it a blend? What is mercerized cotton and why does it matter?

This article will decode the science and value of this premium textile. Written from the perspective of textile manufacturing experts, we will guide you through everything from the chemical changes in the fiber to the practical benefits for apparel. We will explain mercerized cotton benefits for apparel, how it compares to regular cotton (mercerized cotton vs regular cotton explained), and why that signature shine makes it a staple in luxury fashion.

🏭 Factory Insight

In our years of developing mercerized fabrics at the factory, my (Helen’s) most direct observation is this: mercerization doesn’t just change the shape of the cotton fiber (from a flat, kidney-bean shape to a rounder cross-section); it fundamentally alters its behavior. It becomes easier to dye, reflects light more uniformly, and feels “crisper” to the touch.

Before any bulk production, we always run a pilot test: using a 20–26% NaOH concentration, controlling tension on the stenter frame, and recording the K/S curves (color strength) and ΔE (color difference) with a spectrophotometer before and after dyeing. We have found that stable tension control and thorough soaping are more critical for reproducible luster and color accuracy than simply increasing alkali concentration.

This is why high-end shirtings and knitted POLOs universally adopt the mercerization process; industry data clearly shows it significantly boosts dye uptake, strength, and luster—it’s not just about “looking good.” (Reference: CottonWorks™ and Britannica definitions).

⚗️ What is the Mercerization Process?

Before explaining what mercerized cotton is, we need to understand what the mercerization process is.

Simply put, The mercerization process steps are a precise chemical engineering feat. It usually occurs during the finishing stage of textile production.

🔥 Step 1: Singeing (Optional but Recommended)

Before mercerizing, the fabric is often passed over a flame to burn off protruding surface fibers. This enhances the final smoothness.

🧪 Step 2: Impregnation (The Chemical Reaction)

The core of the process involves immersing the yarn or fabric in a bath of Sodium Hydroxide (NaOH) at a specific concentration (usually 20-26% Baumé). This is where the mercerized cotton fiber shape change happens.

📏 Step 3: Tensioning (Crucial Step)

Mercerization under tension explained: If you soak cotton in caustic soda without holding it tight, it will shrink aggressively and become thick and elastic (a process called “slack mercerization,” used for elastic bandages). To achieve luster, the fabric must be held under high tension on a stenter frame. This tension prevents shrinking and forces the fibers to align perfectly, creating the shine.

🚿 Step 4: Stabilization and Washing

While still under tension, the fabric is washed to remove the caustic soda. This “locks in” the new physical structure of the fiber.

🧼 Step 5: Neutralization and Soaping

Finally, a mercerized cotton neutralization and soaping process using weak acid ensures no alkali remains, preventing skin irritation or fiber damage over time.

🏭 Process & Standards (Expertise + Authority)

The process essentials can be summarized in one sentence: 20–26% NaOH + Wetting Agent → Tension/Stentering → Thorough Washing/Neutralization → Soaping → Re-damping.

If the tension is insufficient, the fiber “de-twisting” will be incomplete, compromising both luster and dye uptake advantages. If neutralization/soaping is inadequate, residual alkali will cause the fabric to feel stiff (“boardy”) and lead to color shifting.

Industry literature confirms the chemical mechanism of mercerization and the decisive role of tension in creating luster (History traces back to John Mercer’s invention, later refined by Horace Lowe who discovered that “tension creates luster”). (Reference: [External Link: Wikipedia]).

This is typically part of the finishing process. For a broader look at where this fits in, read how-cotton-is-made-into-fabric-process.

🧶 What Is Mercerized Cotton?

Define mercerized cotton: It is a natural cotton fiber that has been treated with a specific chemical solution (typically Sodium Hydroxide) under tension. This process causes the fibers to swell, untwist, and become rounder, resulting in a fabric that is smoother, stronger, and has a permanent, silk-like sheen.

🤔 However, here, we need to make it clear first: is mercerized cotton 100 percent cotton?

Yes. It is not a synthetic blend. It is pure cotton that has been enhanced.

💎 What is Double Mercerized Cotton?

You may see the “double mercerized” label meaning on very high-end items like luxury golf polos. This indicates that the cotton was mercerized twice: once at the yarn stage (mercerized cotton yarn) and again after it was woven or knitted into fabric. This maximizes the luster and color depth to the highest possible degree.

⚖️ The Pros and Cons of Mercerized Cotton

Why do brands pay a premium for mercerized cotton fabric? Let’s weigh the advantages of mercerized cotton list against the downsides.

✅ Advantages (Why it’s Premium)

- Lustrous Appearance: The most obvious benefit is the “silk-like” shine. It elevates a basic cotton product into the luxury category.

- Vivid Color & Dye Affinity: The structural change allows the fiber to absorb more dye. Mercerized cotton strength and dye uptake are significantly improved, meaning blacks are deeper and brights are more vibrant. This answers the question: does mercerized cotton fade less over time? Yes, the dye penetrates deeper.

- Increased Strength: Surprisingly, the process makes the cotton stronger. The swelling eliminates weak points in the fiber structure.

- Reduced Shrinkage: Because the fabric is pre-shrunk under tension during the process, does mercerized cotton shrink less than untreated cotton? Generally, yes. It offers better dimensional stability.

- Resistance to Mildew: The chemical process removes natural impurities that can attract mildew.

⚠️ Disadvantages (Things to Know)

- Cost: It requires expensive chemicals, specialized machinery, and significant water/energy. This is why mercerized cotton price per kg is higher.

- Wrinkling: While strong, the fibers lose some of their natural elasticity (if not knit). Disadvantages of mercerized cotton cost wrinkle issues are real; it can be slightly more prone to creasing than unmercerized cotton if not treated with an easy-care finish.

- Reduced Breathability (Slight): The fibers swell, closing up the gaps in the weave slightly. However, is mercerized cotton breathable and comfortable? Yes, it is still 100% cotton and very breathable, just marginally less so than a very loose, unmercerized weave.

🧪 In-House Lab Data

Our In-House Lab Data (Fabric-Supplier, 2024)

Spec: Knitted Jersey (200–240 g/m², Ring-Spun)

- Dyeing Efficiency: For the same target color depth, the dye quantity required for mercerized cotton decreased by an average of 22–28%. This saving is most obvious in deep colors like Black and Navy.

- Strength: Warp breaking strength increased by an average of 10–15%.

- Luster/Appearance: A better balance between specular and diffuse reflection, with more stable ΔE (color difference) control.

- Downside: Process costs and energy consumption increased. It demands stricter discipline in pre-treatment cleanliness, tension control, and neutralization; poor management can lead to a stiff hand-feel or secondary color shading.

Research Validation: These trends align with public research: mercerization reduces crystallinity and increases the ratio of amorphous regions, thereby enhancing fiber wettability and dyeability. Industry data also confirms significant improvements in luster, strength, and dye uptake. (Reference: PMC – PubMed Central). Some studies indicate that to achieve equivalent color depth, dye usage for mercerized fabric can drop to about 7/10ths of unmercerized fabric. (Reference: Aensi Journals).

Mercerized Cotton vs. Unmercerized Cotton (Comparison)

To clarify the mercerized vs unmercerized cotton differences, let’s look at a direct comparison. This helps in understanding mercerized cotton vs regular cotton explained in a practical sense.

| Feature | Mercerized Cotton | Unmercerized (Regular) Cotton |

|---|---|---|

| Luster | High, silk-like sheen | Matte, dull finish |

| Hand-Feel | Smooth, silky, cool touch | Soft, fuzzy, warm touch |

| Color | Vibrant, saturated, fade-resistant | Standard, can look “chalky” over time |

| Strength | Higher tensile strength | Standard strength |

| Pilling | Mercerized cotton pilling resistance is excellent (low fuzz) | Prone to pilling (surface fuzz) |

| Shrinkage | Low (chemically pre-shrunk) | High (unless Sanforized) |

| Cost | Premium price point | Standard / Economy |

👕 Common Uses of Mercerized Cotton

The unique properties of this fabric dictate its best applications.

Apparel

- Mercerized Cotton Fabric for Polo Shirts: This is the most iconic use. A double-mercerized polo has a shine that rivals silk blends.

- Dress Shirts: Mercerized cotton dress shirt fabric (poplin/sateen) is standard for high-end business wear. It looks crisp under a suit jacket.

- Premium T-Shirts: Mercerized cotton for premium t shirts offers a dressier, more “formal” t-shirt look that pairs well with blazers.

- Socks: High-end dress socks are almost always mercerized for strength and color clarity.

Home Textiles

- Bedding: Mercerized cotton sateen bedding advantages include a cool-to-the-touch feel and a hotel-luxury aesthetic.

- Table Linens: Napkins and tablecloths benefit from the stain resistance and durability.

Crafts

Threads: Mercerized thread and mercerized cotton crochet thread are preferred by crafters because they glide through fabric easily and don’t fray or fluff. Mercerized cotton embroidery floss and thread provides the necessary sheen for decorative stitching.

📊 Customer Case

A European Men’s Shirting Brand:

The client’s goal was a Navy Blue surface that was “brighter, crisper, and cleaner,” while reducing batch-to-batch ΔE (color) variations. We changed their original recipe to: “More thorough scouring → Mercerization (calibrated tension curve) → Soaping → Disperse/Reactive combination.”

After 3 mass production runs:

- Dye quantity required to hit target depth dropped by 23%.

- ΔE (variation from standard) improved from 1.60 to 0.85.

- Customer complaints regarding a “greyish/dirty” look were virtually eliminated.

- Re-order cycle shortened by 18%.

These results align with industry knowledge: the comprehensive improvement in dyeability, color clarity, and luster is the core reason high-end shirting and combed knits choose mercerization. (Reference: CottonWorks™).

🛒 Where to Buy Mercerized Cotton Fabric?

For B2B buyers asking where to buy mercerized cotton fabric wholesale, the sourcing landscape is specific.

🏭 The Sourcing Landscape

- Specialized Mills: Not all cotton mills have mercerizing ranges. It requires specific wastewater treatment facilities for the caustic soda.

- China: A mercerized cotton fabric supplier china often offers the best balance of technology and price.

- Sourcing Strategy: Look for mills that specialize in “yarn-dyed” or “high-end shirting” fabrics.

- Online: For small designers, searching for mercerized cotton by the yard online or mercerized cotton fabric by the yard is viable, but for bulk, you need a direct mill relationship.

(If you are looking for reliable suppliers, check our cotton-sourcing-guide for a step-by-step approach.)

🧐 Important Considerations When Buying (For Buyers)

How do you ensure you are getting what you pay for?

🕵️♀️ Verification

How to verify mercerized cotton authenticity?

- Visual: It should have a deep shine, not a surface glitter.

- Wash Test: Wash a sample. If the shine washes off, it was a silicone finish or calendering, not true mercerization.

- Lab Test: Request the “Barium Number” test (AATCC 89). A number between 100-150 indicates mercerization.

📏 Standards

- Colorfastness: Ensure the AATCC colorfastness tests for mercerized cotton (specifically wet rubbing) meet your standards, as deep colors can sometimes rub off if not soaped properly.

- Shrinkage: Check ISO shrinkage test requirements for mercerized cotton. It should be very stable.

- Sustainability: Look for OEKO TEX mercerized cotton suppliers to ensure the caustic soda has been neutralized and the wastewater treated responsibly.

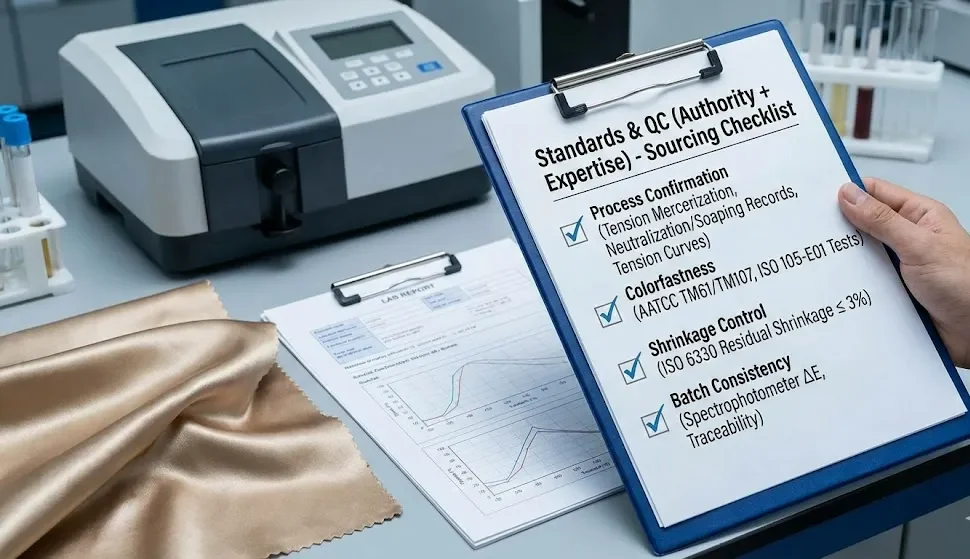

🏭 Standards & QC

We suggest this Sourcing Checklist:

- Process Confirmation: Is it tension mercerized (yarn/fabric)? Are there records of neutralization/soaping and tension curves available?

- Colorfastness: Ask the factory for Colorfastness to Washing and Water/Perspiration tests according to AATCC/ISO standards (e.g., AATCC TM61, TM107 or equivalent ISO 105-E01), performed with standard non-fluorescent detergent.

- Shrinkage Control: Re-test residual shrinkage ≤ 3% according to ISO 6330 home laundry procedures.

- Batch Consistency: Request spectrophotometer ΔE statistics and work order traceability (batch #/operator/key parameters).

These items translate “looking shiny” into acceptance technical metrics, ensuring quality and repeat orders.

🧺 How to Care for Mercerized Cotton

To keep that luxury shine, proper care is needed.

🌊 Washing

- How to wash mercerized cotton shirts: Turn inside out to protect the surface.

- Can you machine wash mercerized cotton: Yes, but use a gentle cycle with cold water (30°C). High heat can degrade the finish over many years.

- Detergent: Best detergent for mercerized cotton is a mild liquid detergent without bio-enzymes or bleaching agents, which can dull the color.

🔥 Drying & Ironing

Can mercerized cotton go in dryer: Ideally, no. Line dry or lay flat. If you must, use low heat.

💡 The Ironing Secret

Ironing tips to restore mercerized cotton luster: Iron the fabric while it is slightly damp (or use heavy steam) on a medium-hot setting. This re-aligns the fibers and makes the shine “pop” again.

(For detailed care instructions for all cotton types, refer to our how-to-wash-pure-cotton guide.)

🏁 Conclusion

Is mercerized cotton worth the premium?

For brands positioning themselves in the mid-to-high-end market, the answer is an emphatic yes. It is the “complete package” of cotton: the natural comfort of the fiber, upgraded with the aesthetics and performance of a synthetic.

🎯 Who should choose mercerized cotton fabric?

- Designers of luxury resort wear.

- Brands selling “investment piece” t-shirts.

- Hotels requiring durable, high-sheen bedding.

By understanding the process and the benefits, you can source this exceptional material with confidence.

(Ready to upgrade your fabric quality? Contact-us to request our mercerized cotton color cards and samples.)

❓ FAQ (Frequently Asked Questions)

Is mercerized cotton 100 percent cotton?

Yes. Mercerization is a treatment applied to the fiber, not a different material. It remains a natural, biodegradable fiber.

Does mercerized cotton shrink after washing?

It shrinks significantly less than regular cotton because the mercerization process pre-shrinks the fabric under tension. However, like all cotton, it may shrink slightly (1-3%) if exposed to high heat.

Is mercerized cotton breathable for summer?

Yes. Is mercerized cotton breathable? While the fibers are swollen, the fabric remains highly breathable and absorbent, making it excellent for summer wear, often feeling cooler to the touch than fuzzy regular cotton.

Mercerized cotton vs polyester which is better?

Mercerized cotton is better for breathability, natural feel, and luxury appearance. Polyester is better for extreme durability and moisture-wicking in athletic contexts.

(See our full comparison: [Internal Link: /cotton-vs-polyester-fabric-expert-comparison/])

Mercerized cotton thread vs polyester thread for sewing?

Mercerized cotton thread is preferred for sewing natural fabrics (like cotton or linen) because it shrinks at the same rate as the fabric, preventing puckering. Polyester thread is stronger but can cut through delicate cotton fibers over time.